Raw petroleum demulsifying agent and preparation method thereof

A crude oil demulsifier and demulsifier technology, applied in the field of petroleum additives, can solve the problems of poor crude oil adaptability and low demulsification efficiency, achieve low demulsification temperature, reduce crude oil production cost, and be easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

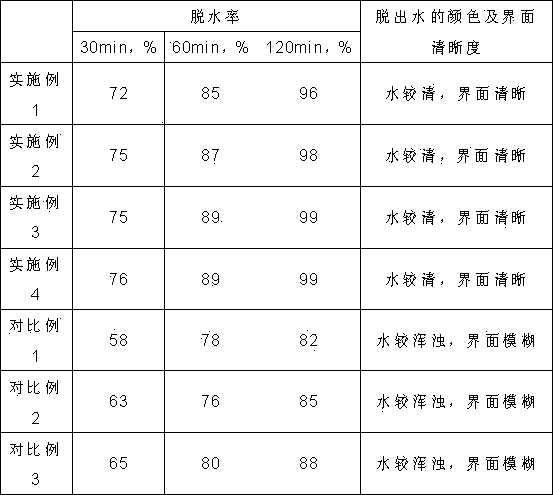

Examples

Embodiment 1

[0020] A crude oil demulsifier, comprising the following components in parts by weight: 1 part of Sangjisheng, 0.1 part of Fangji, 10 parts of polyoxypropylene-polyoxyethylene block copolymer, 0.01 part of demulsifier XH-1, three 2 parts of phosphorus oxychloride, 1 part of borax, 5 parts of hexamethylenetetramine, 0.1 part of fluorocarbon surfactant, 5 parts of ethanol, 1 part of pentaerythritol, and 80 parts of water.

[0021] The preparation method of the embodiment crude oil demulsifier of the present invention, comprises the steps:

[0022] Step (1), crush Sangjisheng and Fangji to 100-200 meshes, add water 4 times its mass, heat at 60°C for 2 hours, cool down to room temperature, centrifuge, take supernatant, pass through 0.22 microns filter membrane to obtain solution A; wherein, the centrifugation speed is 3000r / min, and the centrifugation time is 10min;

[0023] Step (2), put the polyoxypropylene-polyoxyethylene block copolymer in the reaction kettle, add phosphorus ...

Embodiment 2

[0026] A crude oil demulsifier, comprising the following components in parts by weight: 3 parts of Sangjisheng, 0.4 parts of Fangji, 15 parts of polyoxypropylene-polyoxyethylene block copolymer, 0.05 parts of demulsifier XH-1, three parts 5 parts of phosphorus oxychloride, 3 parts of borax, 8 parts of organic auxiliary agent, 0.2 part of fluorocarbon surfactant, 7 parts of ethanol, 3 parts of pentaerythritol, 100 parts of water; described organic auxiliary agent is diethylamine and monoethanolamine Mixture, its specific ratio is not required.

[0027] The preparation method of the embodiment crude oil demulsifier of the present invention, comprises the steps:

[0028] Step (1), crush Sangjisheng and Fangji to 100-200 mesh, add water 7 times its mass, heat at 80°C for 4 hours, cool down to room temperature, centrifuge, take supernatant, pass through 0.22 microns filter membrane to obtain solution A; wherein, the centrifugation speed is 3000r / min, and the centrifugation time is...

Embodiment 3

[0032] A crude oil demulsifier, comprising the following components in parts by weight:

[0033] 2 parts of Sangjisheng, 0.3 parts of Fangji, 13 parts of polyoxypropylene-polyoxyethylene block copolymer, 0.04 parts of demulsifier XH-1, 3 parts of phosphorus oxychloride, 2 parts of borax, 7 parts of organic additives, fluorine 0.14 parts of carbon surfactant, 6 parts of ethanol, 2 parts of pentaerythritol, and 87 parts of water; the organic auxiliary agent is a mixture of hexamethylenetetramine, diethylamine and triethylamine, and its specific ratio is not required.

[0034] The preparation method of the embodiment crude oil demulsifier of the present invention, comprises the steps:

[0035] Step (1), crush Sangjisheng and Fangji to 100-200 meshes, add water 6 times its mass, heat at 72°C for 3 hours, cool down to room temperature, centrifuge, take supernatant, pass through 0.22 microns filter membrane to obtain solution A; wherein, the centrifugation speed is 3000r / min, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com