UV-curable polyolefin optical film and preparation method thereof

A technology of optical film and polyolefin, applied in the direction of film/sheet adhesives, adhesive additives, non-polymer adhesive additives, etc., which can solve the problems of poor insulation, poor water vapor barrier, and long-term use of electrodes, etc. problems, to achieve the effect of long service life, not easy to air bubbles, and low water vapor transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

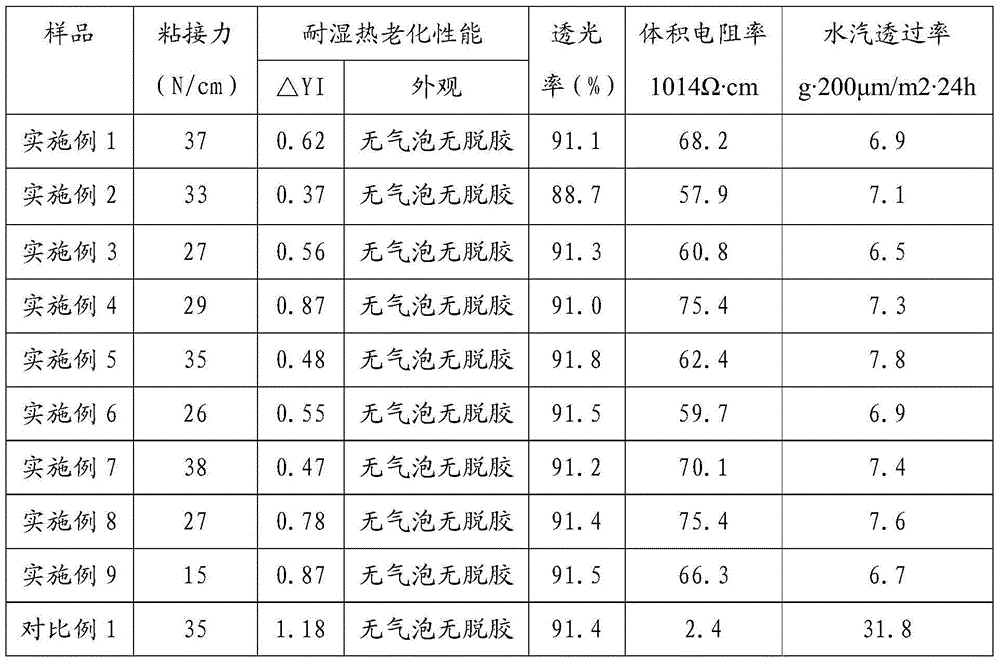

Examples

Embodiment 1

[0029] Add 0.1 part of pentaerythritol triacrylate, 0.3 part of photoinitiator benzoin dimethyl ether, 1 part of co-crosslinking agent in 100 parts by weight of octene content of 62%, melting point of ethylene-octene copolymer of 41 ° C Triallyl isocyanurate, 0.05 parts of light stabilizer 2-(2'-hydroxy-5'-methylphenyl)-benzotriazole, 0.05 parts of antioxidant tris(nonylbenzene Base) phosphite, 1.0 parts of coupling agent γ-(methacryloyloxy)propyltrimethoxysilane, mixed uniformly by a mixer, put into a casting machine, and plasticized and extruded at 80°C out, stretching, pulling, and winding to make a film with a thickness of about 0.2mm.

Embodiment 2

[0031] Add 0.1 part of ditrimethylolpropane triacrylate, 2 parts of photoinitiator benzophenone, 0.5 part of Light stabilizer 2-(2'-hydroxy-5'-methylphenyl)-benzotriazole, 0.5 parts of antioxidant tris(nonylphenyl) phosphite, 0.6 parts of coupling agent γ-(Methacryloyloxy)propyltrimethoxysilane is uniformly mixed by a mixer, put into a tape casting machine, and plasticized, extruded, stretched, drawn, and rolled at 80°C to make a thickness About 0.2mm film.

Embodiment 3

[0033] Add 2 parts of pentaerythritol triacrylate, 2 parts of photoinitiator benzoin dimethyl ether, 1 part of co-crosslinking agent in 100 parts by weight of octene content of 55% and 52 ℃ of ethylene-octene copolymers Pentaerythritol tetraacrylate, 0.2 parts of light stabilizer 2-(2'-hydroxy-5'-methylphenyl)-benzotriazole, 0.2 parts of antioxidant tris(nonylphenyl)phosphite , mixed evenly by a mixer, put into a casting machine, plasticized, extruded, stretched, drawn, and rolled at 80°C to make a film with a thickness of about 0.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com