A kind of lincomycin hydrochloride purification process

A lincomycin hydrochloride and process technology, applied in the field of lincomycin hydrochloride purification technology, can solve the problems such as the inability to reduce the B component of lincomycin hydrochloride, and achieve the effects of increasing final yield and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

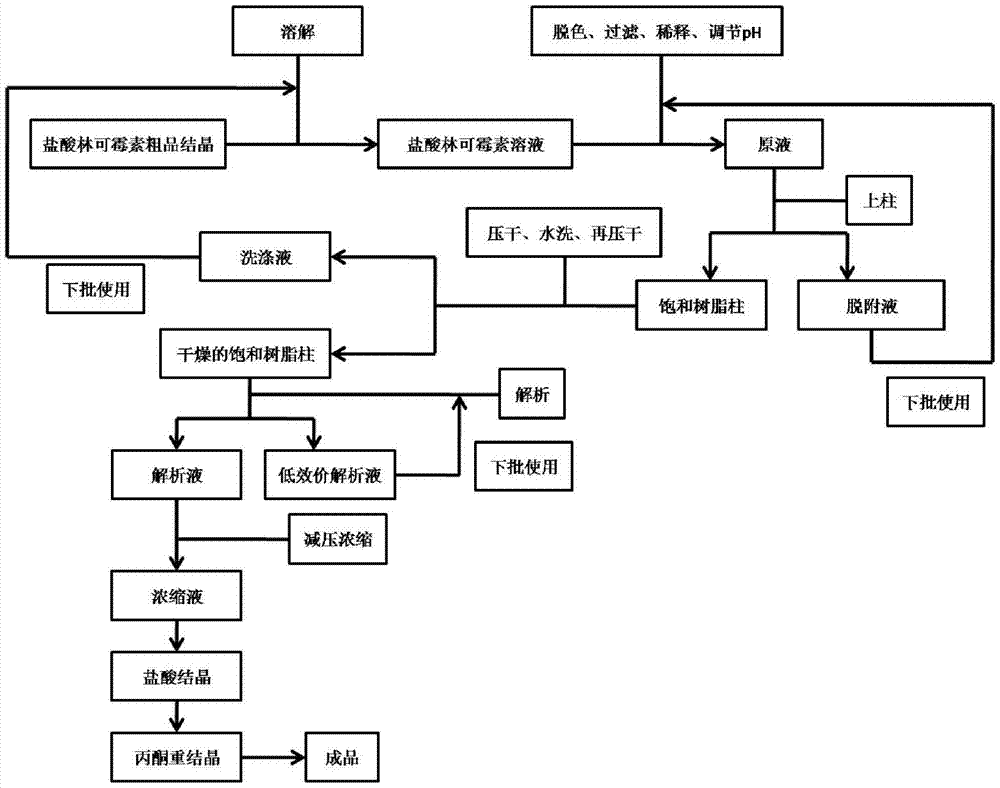

[0034] refer to figure 1 , a kind of lincomycin hydrochloride purification process, the resin column selected is or LX-20 type macroporous resin, the lincomycin A component 85wt% in the lincomycin hydrochloride crude product crystallization that selects, lincomycin B component 14wt%, other impurity 1wt%; Technology comprises the following steps:

[0035] S1. Adsorption step: Put 100 kilograms of lincomycin hydrochloride crude product crystals into a dissolving tank, add pure water to dissolve, and obtain an aqueous solution with a titer of 300,000 units, add activated carbon to decolorize the solution, and after decolorization is completed, filter and press Put it into the stock solution irrigation, add pure water to dilute it, adjust the pH of the solution to 10.5, and obtain the stock solution. / hr, detect the titer of the desorption liquid at the outlet of the resin column, and discard the ineffective desorption liquid. When it is detected that the titer of the desorption...

Embodiment 2

[0043] refer to figure 1 , a lincomycin hydrochloride purification process, the resin column selected is LSA-100 type macroporous resin column, lincomycin A component 85wt% in the lincomycin hydrochloride crude product crystallization that selects, lincomycin B Component 14wt%, other impurity 1wt%; Technology comprises the steps:

[0044]S1. Adsorption step: Put 100 kg of lincomycin hydrochloride crude product crystals into a dissolving tank, add purified water to dissolve, and obtain an aqueous solution with a titer of 320,000 units, add activated carbon to decolorize the solution, and after decolorization is completed, filter, press Put it into the stock solution irrigation, add pure water to dilute it, adjust the pH of the solution to 10.6, and obtain the stock solution. / hr, detect the titer of the desorption liquid at the outlet of the resin column, and discard the ineffective desorption liquid. When it is detected that the titer of the desorption solution is 26,000 uni...

Embodiment 3

[0052] refer to figure 1 , a lincomycin hydrochloride purification process, the resin column selected is LSA-100 type macroporous resin column, lincomycin A component 85wt% in the lincomycin hydrochloride crude product crystallization that selects, lincomycin B Component 14wt%, other impurity 1wt%; Technology comprises the steps:

[0053] S1. Adsorption step: put 100 kg of lincomycin hydrochloride crude product crystals into a dissolving tank, add pure water to dissolve, and obtain an aqueous solution with a titer of 350,000 units, add activated carbon to decolorize the solution, and after decolorization is completed, filter and press Put it into the stock solution irrigation, add pure water to dilute it, adjust the pH of the solution to 11.5, and obtain the stock solution. / hr, detect the titer of the desorption liquid at the outlet of the resin column, and discard the ineffective desorption liquid. When it is detected that the titer of the desorption solution is 40,000 uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com