Plasma pyrolytic coal-derived acetylene reactor

A plasma and pyrolysis reaction technology, applied in the field of reactors, can solve the problems of difficult uniform temperature in the reaction zone, large heat loss in the reactor, and generation of oxidizing atmosphere, so as to improve reaction efficiency, increase acetylene yield, and reduce heat energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

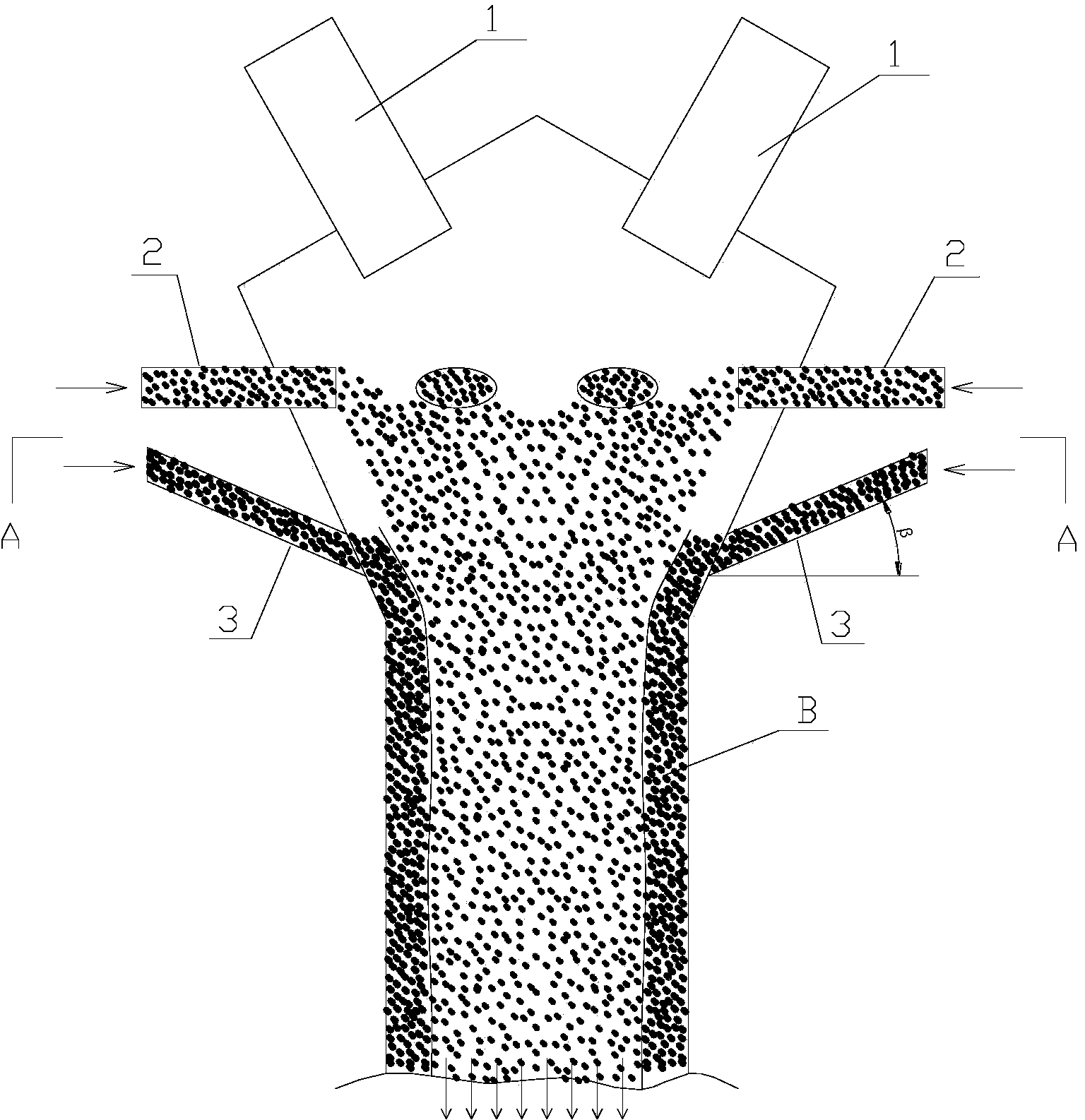

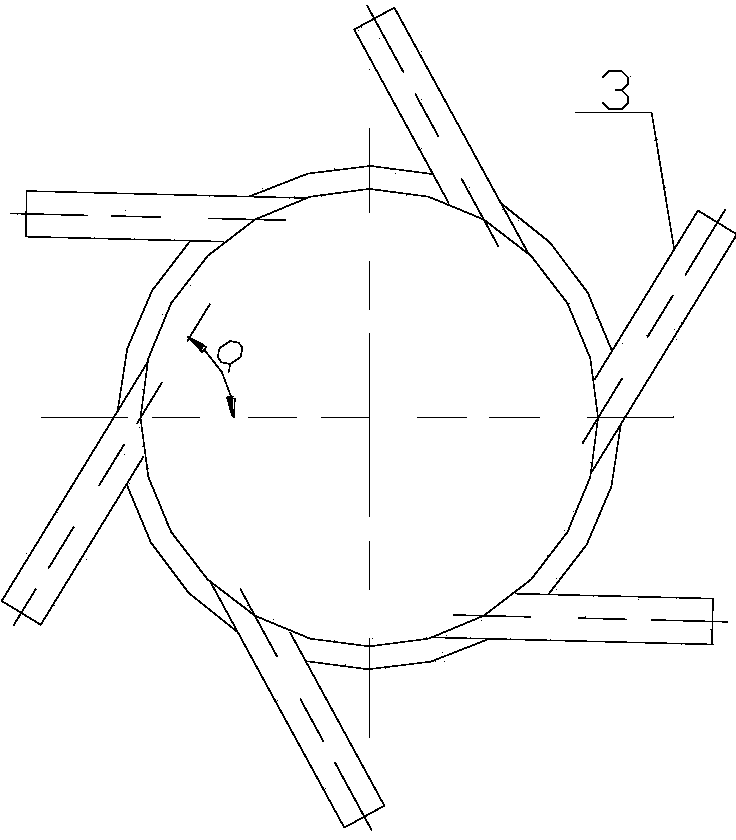

[0022] Such as Figure 1-Figure 2 as shown, figure 1 It is a structural schematic diagram of a plasma pyrolysis coal-to-acetylene reactor proposed by the present invention, figure 2 for figure 1 Middle A-A sectional view.

[0023] refer to Figure 1-2 , a plasma pyrolysis coal-to-acetylene reactor proposed by the present invention, a plurality of arc plasma generators 1 and a plurality of pulverized coal input nozzles 2 are installed above the reactor, and the high-temperature ionized gas generated by the arc plasma generator 1 It is mixed with the pulverized coal ejected from the pulverized coal input nozzle 2 to form a pulverized coal gas mixed reactant, and then flows down into the pulverized coal heating pyrolysis reaction section below the reactor, where the pulverized coal heats up the temperature rising gas rapidly in the pulverized coal heating pyrolysis reaction section and generate acetylene; multiple solid powder nozzles 3 are installed on the reactor, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com