Flexible pressing device for low-rigidity components and assembling and pressing method of flexible pressing device

A compression device and weak rigidity technology, applied in the direction of workpiece clamping device, assembly machine, metal processing equipment, etc., can solve the problems of high manufacturing cost, bulky, large device volume, etc., to avoid damage, avoid damage, good clamping The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the detailed description of the following embodiments, the detailed implementation and specific operation process are given on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following examples.

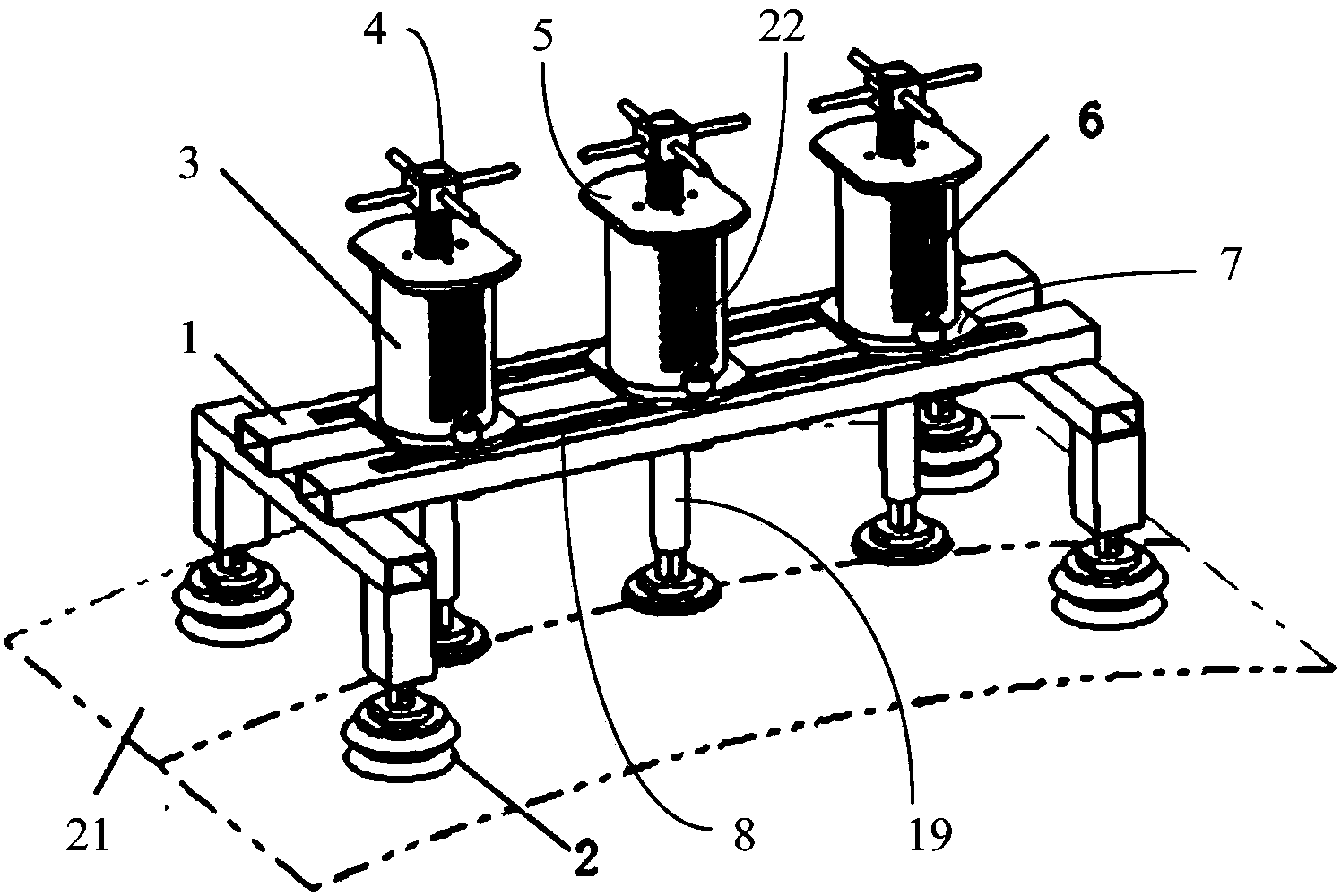

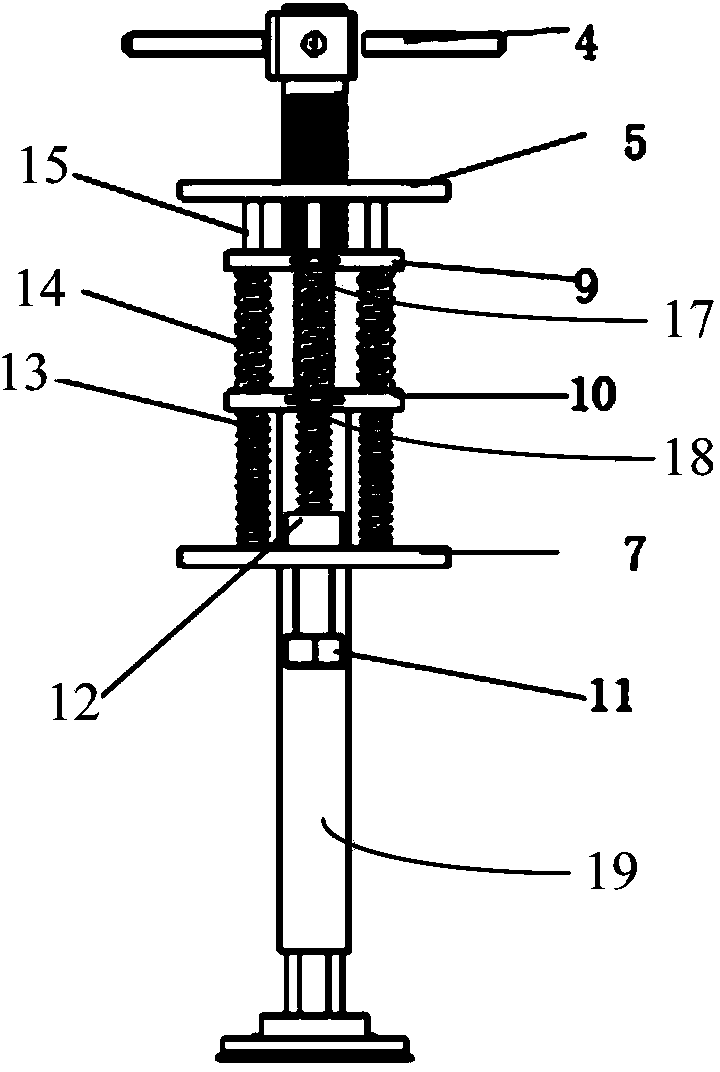

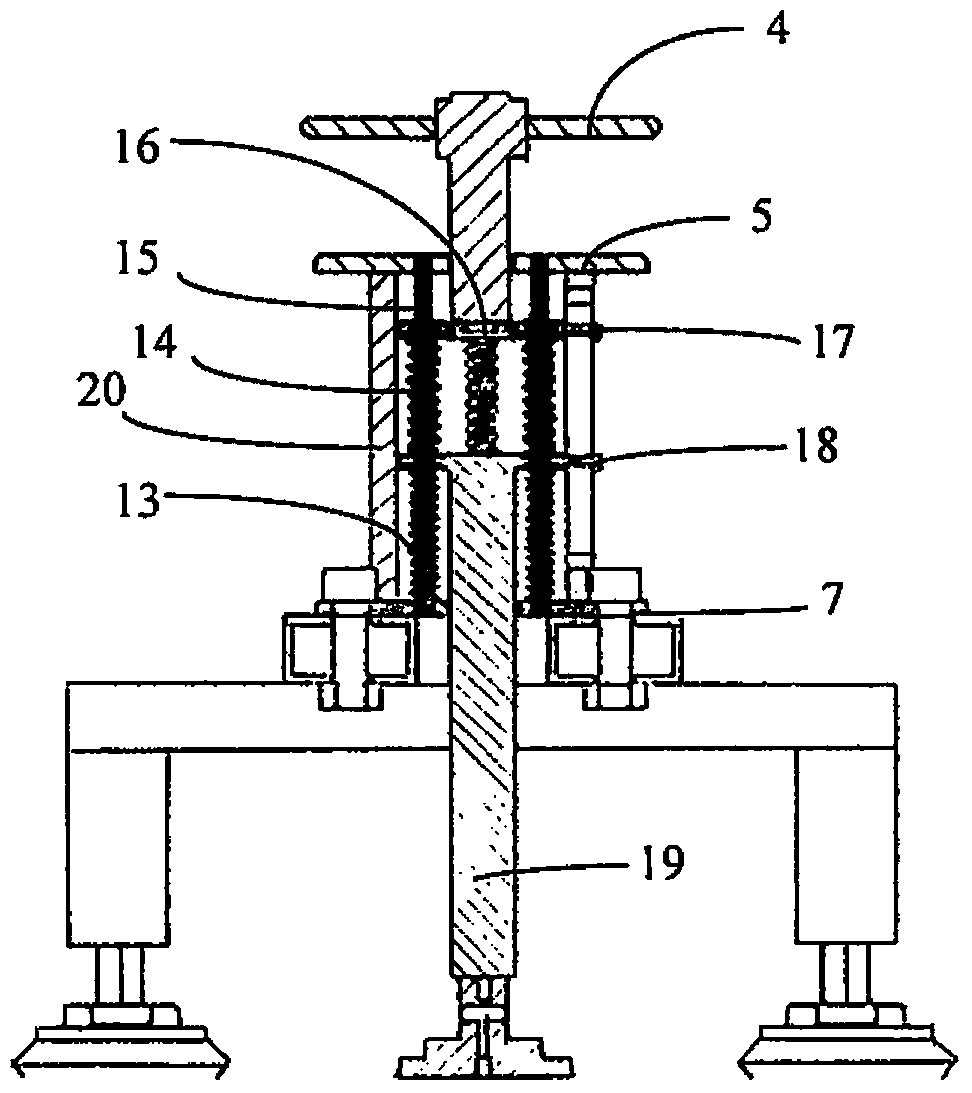

[0027] see first figure 1 , the flexible pressing device for weakly rigid parts according to the present invention is used for assembling and pressing the aircraft weakly rigid panel parts 21 exemplified by dotted lines. In the illustrated embodiment, the flexible pressing device includes a clamping assembly 2 for positioning and clamping the parts 21 to be connected or docked, and at least one pressing assembly 3 for pressing the parts 21 in the vertical direction at the connection or docking And a displacement adjustment assembly 1 that adjusts the displacement of the compression assembly 3 in the horizontal direction. Wherein, as shown in the figure, the clamping assembly 2 is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com