A kind of preparation method of high fragrant orchid leaf instant powder

A production method and a high-fragrant pandan technology are applied in the field of food processing, which can solve the problems of aroma loss and affect the aroma of the final product, and achieve the effects of good aroma, excellent application performance and reduced aroma loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

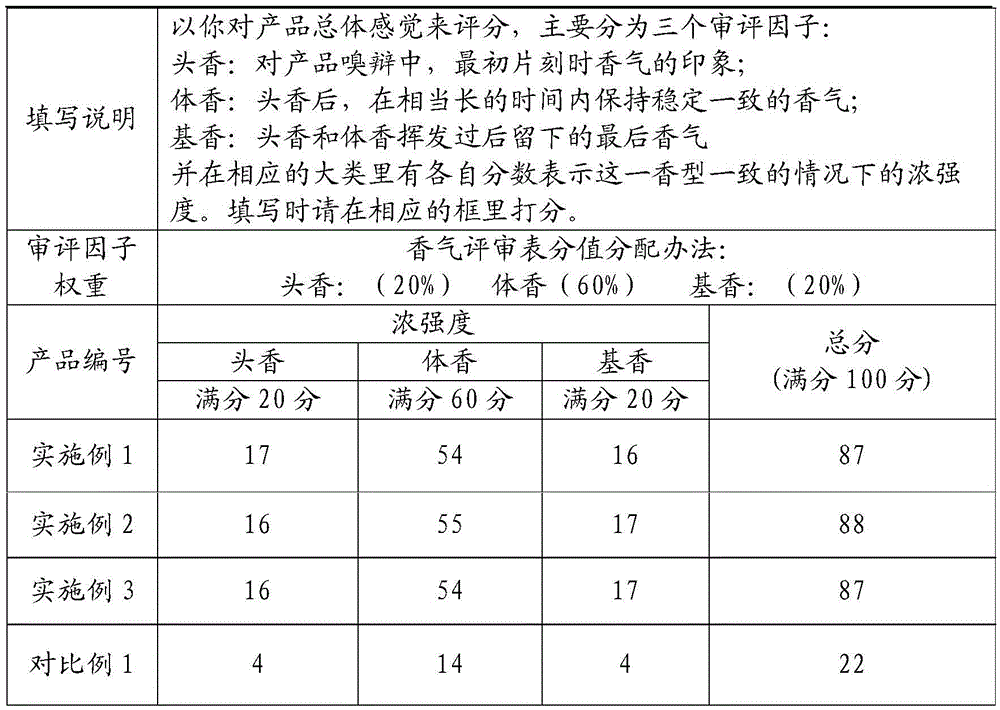

Examples

Embodiment 1

[0023] A kind of preparation method of high-sweet spot blue leaf instant powder, carry out according to the following steps:

[0024] 1) Juicing: Chopping fresh pandan leaves, adding water and squeezing to obtain juice; the amount of water added is twice the weight of fresh pandan leaves.

[0025] 2) Enzymolysis: take the squeezed juice and add cellulase and pectinase for enzymolysis to obtain an enzymolysis solution; add 200 mg of cellulase and 100 mg of pectinase to each kilogram of squeezed juice; control the pH value to 5.0 , the enzymolysis temperature is 45°C, the enzymolysis time is 40min, and the yield is 3.1%;

[0026] 3) Centrifugation: After filtering the enzymatic solution, cool and centrifuge to obtain the centrifuge; the centrifugation temperature is 30°C, the centrifugation speed is 4000rpm, and centrifugation is 10min;

[0027] 4) Concentration: concentrate the centrifugate to 5Brix through a reverse osmosis membrane to obtain a concentrate;

[0028] 5) Freez...

Embodiment 2

[0030] A kind of preparation method of high-sweet spot blue leaf instant powder, carry out according to the following steps:

[0031] 1) Juicing: Chopping fresh pandan leaves, adding water and squeezing to obtain juice; the amount of water added is three times the weight of fresh pandan leaves.

[0032] 2) Enzymolysis: take the squeezed juice and add cellulase and pectinase for enzymolysis to obtain an enzymolysis solution; add 100 mg of cellulase and 80 mg of pectinase to each kilogram of squeezed juice; control the pH value to 5.0 , the enzymolysis temperature is 45°C, the enzymolysis time is 50min, and the yield is 2.9%;

[0033] 3) Centrifugation: After filtering the enzymatic solution, cool and centrifuge to obtain the centrifuge; the centrifugation temperature is 30°C, the centrifugation speed is 4000rpm, and centrifugation is 10min;

[0034] 4) Concentration: Concentrate the centrifugate to 10Brix through a reverse osmosis membrane to obtain a concentrate;

[0035] 5)...

Embodiment 3

[0037] A kind of preparation method of high-sweet spot blue leaf instant powder, carry out according to the following steps:

[0038] 1) Juicing: Chopping fresh pandan leaves, adding water and squeezing to obtain juice; the amount of water added is twice the weight of fresh pandan leaves.

[0039] 2) Enzymolysis: Take the squeezed juice and add cellulase and pectinase for enzymolysis to obtain an enzymolysis solution; add 50 mg of cellulase and 200 mg of pectinase to each kilogram of squeezed juice; control the pH value to 5.0 , the enzymolysis temperature is 45°C, the enzymolysis time is 60min, and the yield is 3.0%;

[0040] 3) Centrifugation: After filtering the enzymatic solution, cool and centrifuge to obtain the centrifuge; the centrifugation temperature is 30°C, the centrifugation speed is 4000rpm, and centrifugation is 10min;

[0041] 4) Concentration: concentrate the centrifugate to 8Brix through a reverse osmosis membrane to obtain a concentrate;

[0042] 5) Freeze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com