Asparagus fermented beverage and preparation method thereof

A technology for fermented beverages and asparagus, which is applied in the field of food manufacturing to achieve the effects of golden and noble color, changing taste, and elegant asparagus aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 prepares asparagus fermented beverage

[0030] (1), select fresh high-quality asparagus as raw material, clean and disinfect the asparagus, then carry out simple ultraviolet sterilization, then send it to a juicer for squeezing, and filter the asparagus juice, preferably with a 150-mesh filter.

[0031] (2), the filtered fresh asparagus juice is sent into the boiler, and the filtered pure water with a volume of 20-25% of the original asparagus juice volume is also sent into the boiler, that is, adding water to dilute the asparagus juice; then at 127 ° C, High temperature and high pressure sterilization under the condition of 1.0-1.2MPa for 5-8min.

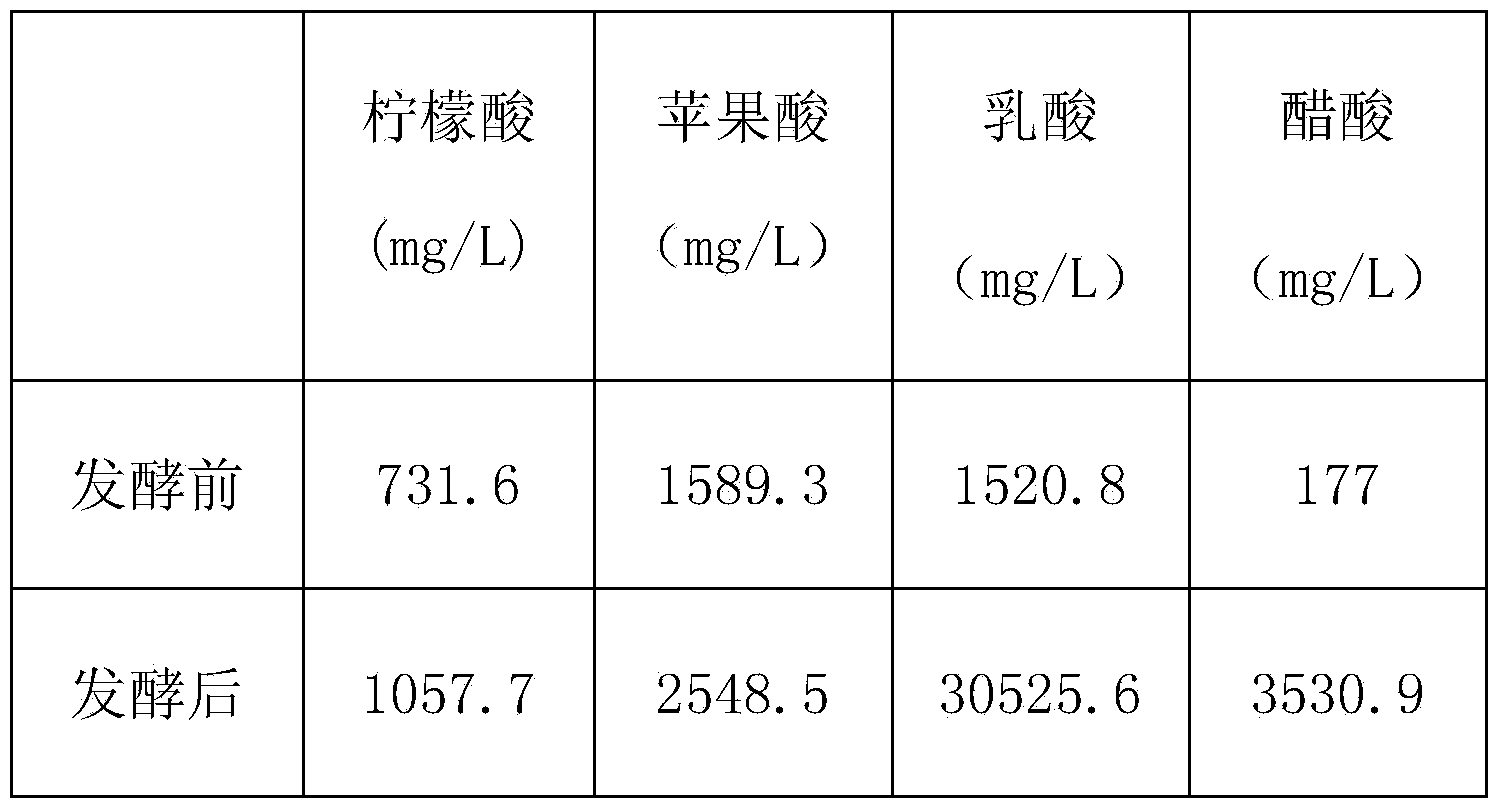

[0032] (3), in asparagus juice, add lactic acid bacteria, saccharomycetes and acetic acid bacteria simultaneously, the mass concentration of lactic acid bacteria, saccharomyces, acetic acid bacillus is successively 50%, 80%, 55%, the added amount is successively 8% of asparagus juice weight ‰, 3.6‰, 2.4‰, and t...

Embodiment 2

[0034] Embodiment 2 prepares asparagus fermented beverage

[0035] (1), select fresh high-quality asparagus as raw material, clean and disinfect the asparagus, then carry out simple ultraviolet sterilization, then send it to a juicer for squeezing, and filter the asparagus juice, preferably with a 150-mesh filter.

[0036] (2), the filtered fresh asparagus juice is sent into the boiler, and the filtered pure water with a volume of 20-25% of the original asparagus juice volume is also sent into the boiler, that is, adding water to dilute the asparagus juice; then at 127 ° C, High temperature and high pressure sterilization under the condition of 1.0-1.2MPa for 5-8min.

[0037] (3), in asparagus juice, add lactic acid bacteria, saccharomycetes and acetic acid bacteria simultaneously, the mass concentration of lactic acid bacteria, saccharomyces, acetic acid bacillus is successively 50%, 80%, 55%, the added amount is successively 8% of asparagus juice weight ‰, 3.6‰, 2.4‰, and t...

Embodiment 3

[0039] Embodiment 3 prepares asparagus fermented beverage

[0040] (1), select fresh high-quality asparagus as raw material, clean and disinfect the asparagus, then carry out simple ultraviolet sterilization, then send it to a juicer for squeezing, and filter the asparagus juice, preferably with a 150-mesh filter.

[0041] (2), the filtered fresh asparagus juice is sent into the boiler, and the filtered pure water with a volume of 20-25% of the original asparagus juice volume is also sent into the boiler, that is, adding water to dilute the asparagus juice; then at 127 ° C, High temperature and high pressure sterilization under the condition of 1.0-1.2MPa for 5-8min.

[0042] (3), in asparagus juice, add lactic acid bacteria, saccharomycetes and acetic acid bacteria simultaneously, the mass concentration of lactic acid bacteria, saccharomyces, acetic acid bacillus is successively 50%, 80%, 55%, the added amount is successively 8% of asparagus juice weight ‰, 3.6‰, 2.4‰, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com