A green recycling method for electrolyte in waste power batteries

A power battery, recycling technology, applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of unavoidable electrolyte, pollution of the environment, physical injury of operators, etc., to achieve low cost and high recovery rate , The effect of solving the problem of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

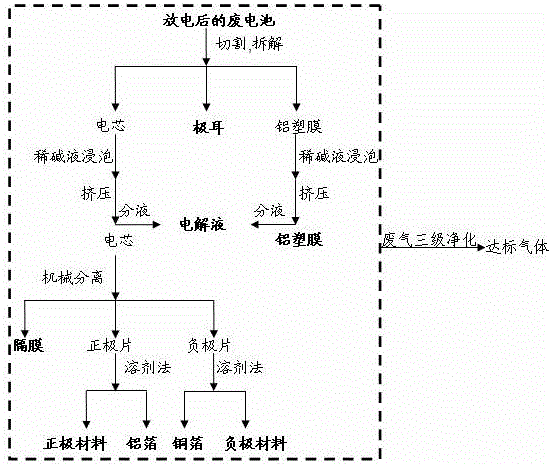

[0019] A green recycling method for electrolyte in waste power batteries, such as figure 2 described, including the following steps:

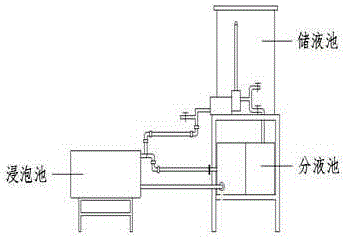

[0020] 1) Ten pieces of 25Ah waste batteries with a mass of 5690 g were discharged and disassembled in a sealed box. The exhaust gas in the box was discharged into the atmosphere after three-stage purification treatment of NMP waste liquid, dilute lye, and water. 40 g of the ears were directly recovered, and the obtained aluminum-plastic film and the electric core were respectively put into the grid frame in the immersion tank of the NaOH aqueous solution with a concentration of 60 L and 0.05mol / L and soaked for 60 minutes. During the soaking process, the grid frame continued to Rotate to facilitate the dissolution of the electrolyte, the dilute lye circulates among the system consisting of the soaking tank, the liquid separation tank and the liquid storage tank, the total amount of the dilute lye in the three pools is 200L, such as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com