Resistive memory and manufacturing method thereof

A resistive memory, electrode technology, applied in static memory, digital memory information, information storage, etc., can solve the problems of poor reset efficiency, increase the time of applying negative bias, and achieve the effect of improving reset efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

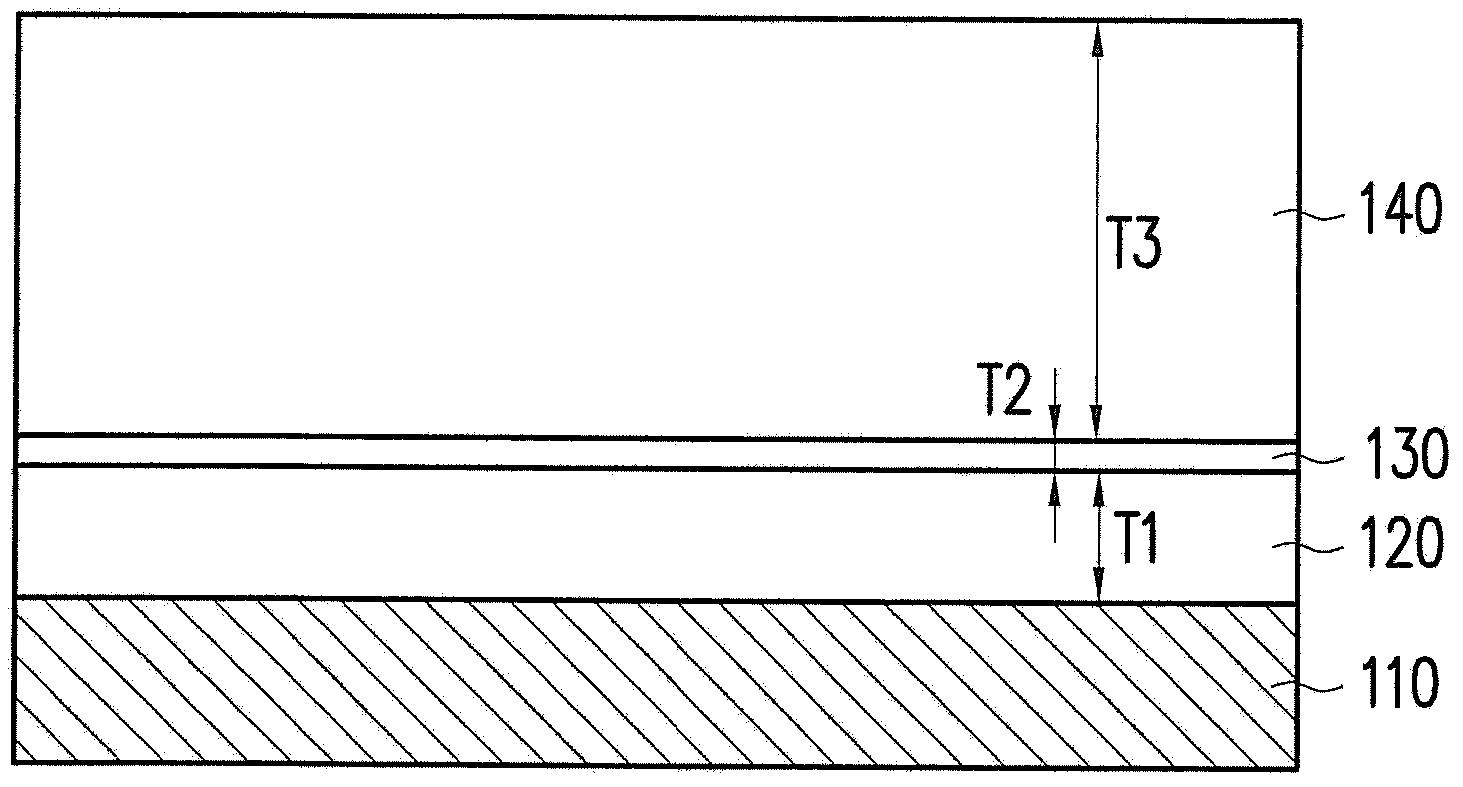

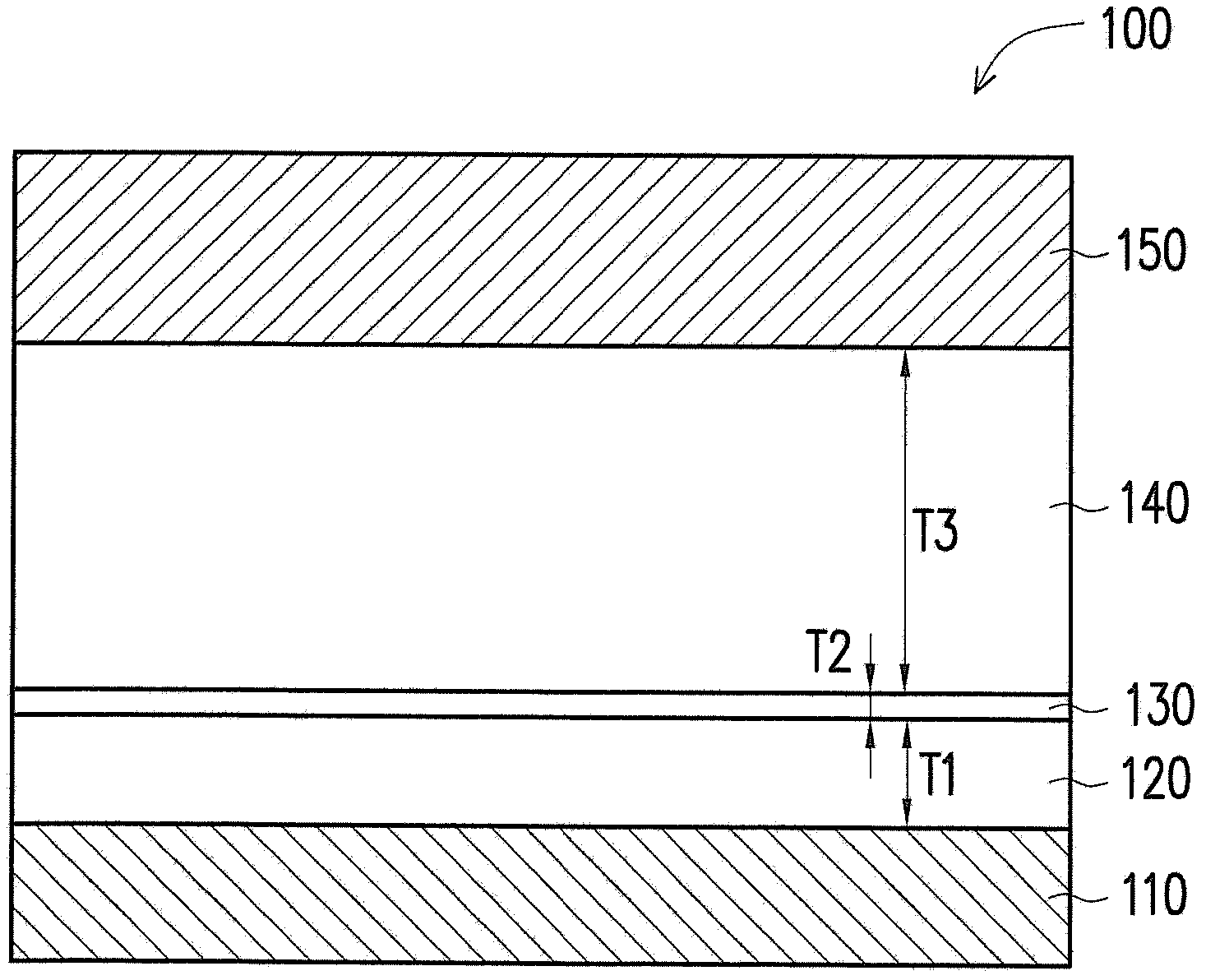

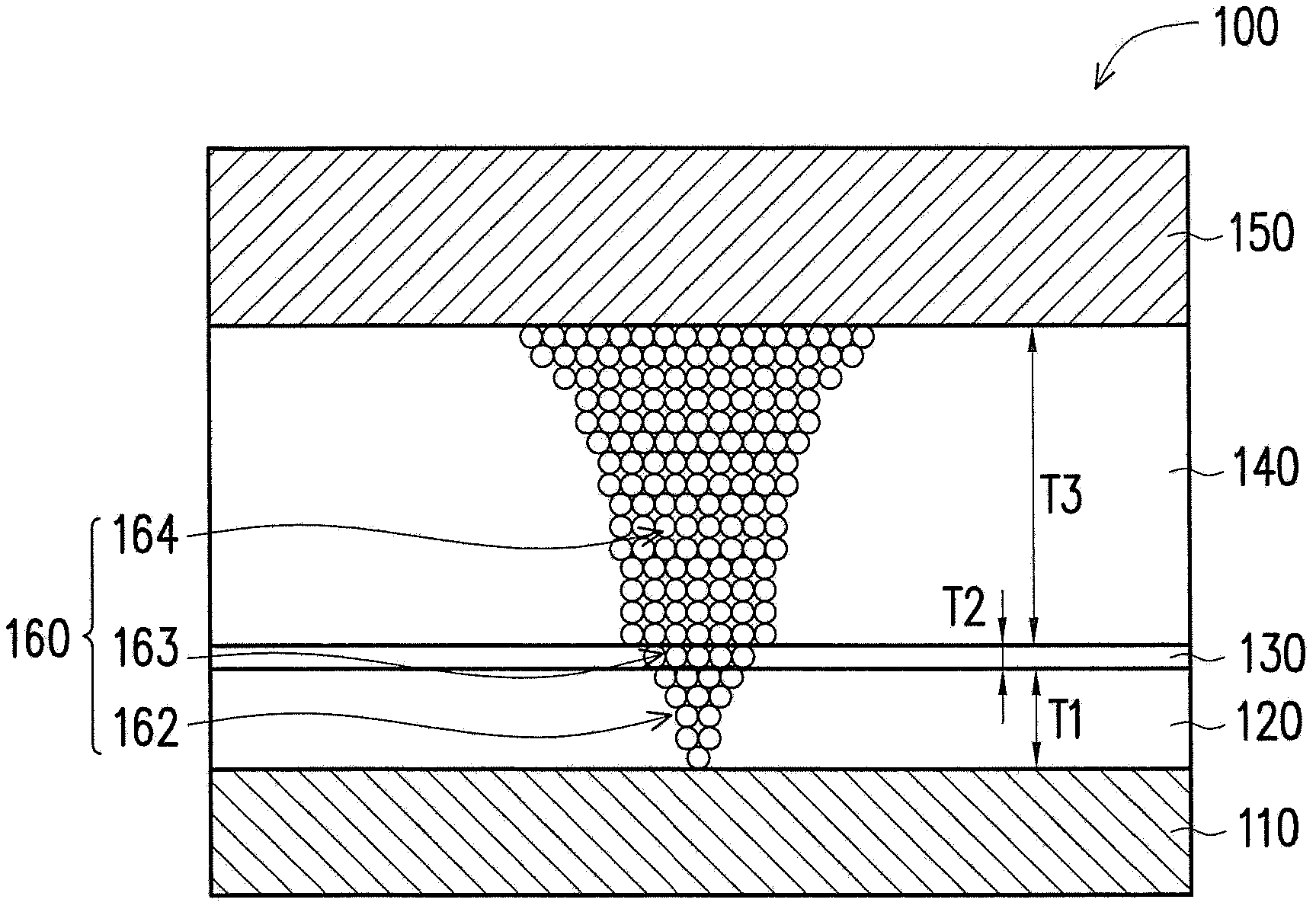

[0027] Figure 1A to Figure 1B It is a schematic cross-sectional view of a manufacturing method of the resistive memory 100 according to an embodiment of the present invention. First, please refer to Figure 1A , forming a first dielectric layer 120 on the first electrode 110 . The material of the first electrode 110 is, for example, titanium nitride (TiN), platinum (Pt), iridium (Ir), ruthenium (Ru), titanium (Ti), tungsten (W), tantalum (Ta), aluminum (Al), Zirconium (Zr), hafnium (Hf), nickel (Ni), copper (Cu), cobalt (Co), iron (Fe), gadolinium (Y) or manganese (Mo) can be formed by physical vapor deposition, for example. The material of the first dielectric layer 120 is, for example, hafnium oxide (such as HfO or HfO 2 etc.), lanthanum oxide, gadolinium oxide, yttrium oxide, zirconium oxide, titanium oxide, tantalum oxide, nickel oxide, tungsten oxide, copper oxide, cobalt oxide or iron oxide, formed by chemical vapor deposition, for example.

[0028] please refer agai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com