Spray nozzle brick for oxy-fuel combustion spray gun, manufacturing method and spray gun and melting furnace with spray nozzle brick

An all-oxygen combustion and nozzle brick technology, which is used in manufacturing tools, glass manufacturing equipment, glass melting devices, etc., can solve the problem that the softening temperature of nozzle bricks cannot meet the requirements of long-term use of all-oxygen combustion furnaces, and all oxygen The operation cost of the combustion furnace is increased, and the stability of the furnace is reduced, so as to achieve the effects of a wide range of fuel use, high flame blackness and less NOx generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

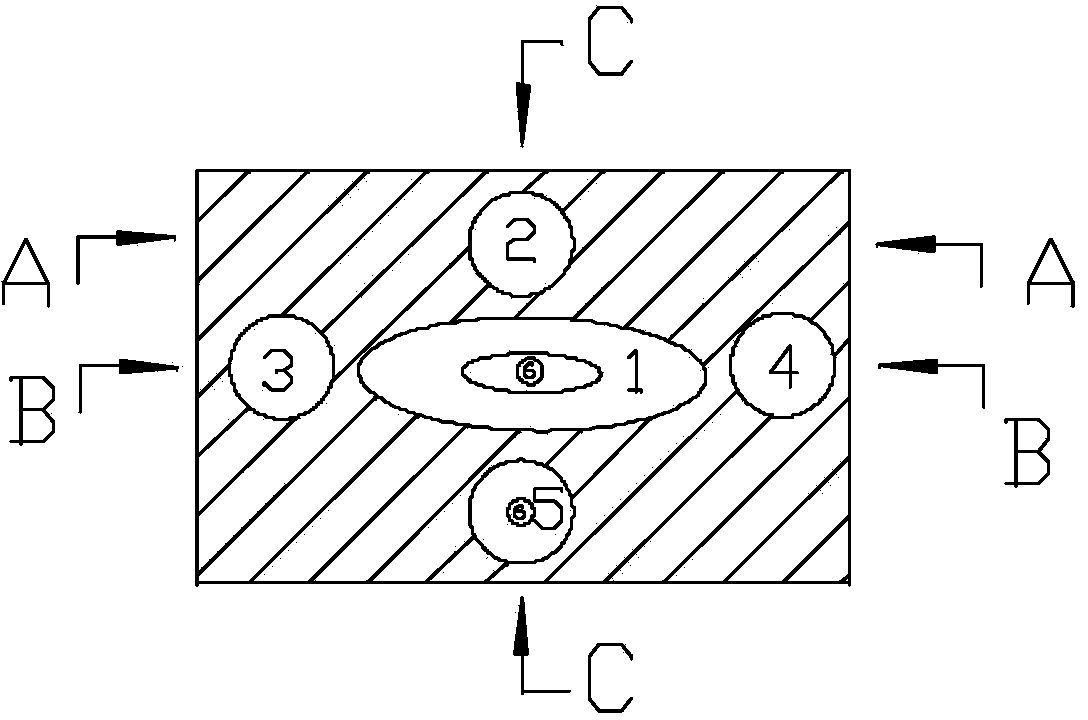

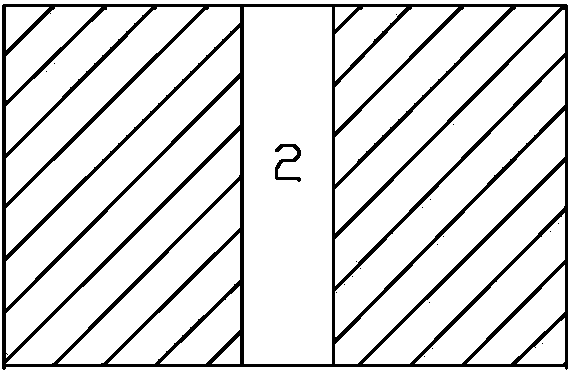

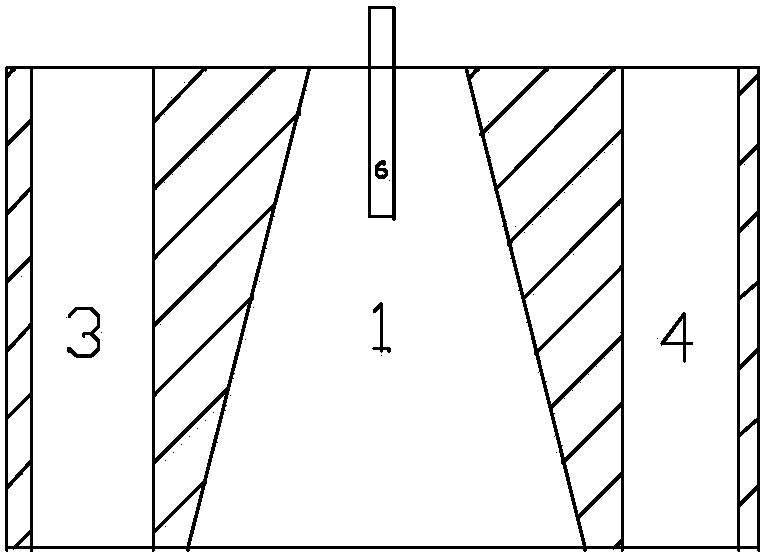

Image

Examples

Embodiment Construction

[0024] The change of the combustion system has caused a change in the structure of the glass melting furnace. The oxy-fuel combustion furnace is like a unit kiln, and the regenerator, small furnace and fire exchange system have been cancelled, but high-quality refractory materials are required. The oxy-fuel combustion oxygen lance is located in the side wall of the upper structure of the molten pool so as to burn across the surface of the molten glass; the spray lance should be arranged reasonably on the kiln, and the heat required for melting glass should be supplied according to the partition to ensure temperature uniformity across the kiln width. The combustion products pass through the furnace, leave the furnace at the other end, pass through the exhaust flue, and enter the chimney for discharge.

[0025] Oxy-fuel combustion lance and nozzle brick are one of the symbols of oxy-fuel combustion technology. At the same time, the performance and quality of oxy-fuel combustion l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com