Pebble coal collecting system

A collection system and pebble coal technology, applied in conveyors, grain processing, transportation and packaging, etc., can solve the problems of pebble coal coke clogging pipe water consumption, high production costs, saving use costs, reducing production costs, avoiding The effect of coke blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

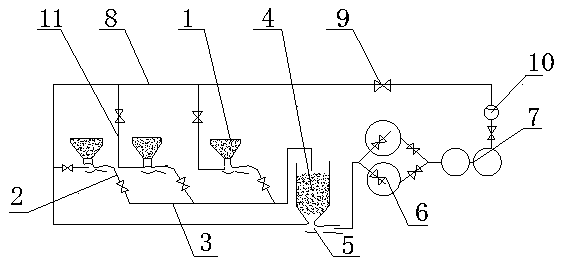

[0015] See attached figure 1 As shown, a kind of gravel coal collection system of the present invention comprises a plurality of water-sealed gravel coal hoppers 1, and the shape of the water-sealed gravel coal hoppers 1 is a square cone shape, and the discharge of the water-sealed gravel coal hoppers 1 The outlets are respectively connected to the main conveying pipeline 3 through the branch pipeline 2, and the end of the main conveying pipeline 3 is connected to the pebble coal collection bin 4. Dehydration chamber 6, the rear of dehydration chamber 6 is provided with water purification treatment and storage device 7, is connected with main water pipeline 8 on water purification treatment and storage device 7, is provided with valve 9 and high-pressure pump 10 on main water pipeline 8, main water The pipeline 8 is provided with a water diversion pipeline 11 respectively connected with the water-sealed gravel coal hopper 1 . Because the shape of the pebble coal hopper 1 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com