Steel plate coiling device

A technology of steel plate coiling and tapered grooves, which is applied in the field of steel plate coiling devices to achieve the effect of flexible sliding and favorable coiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

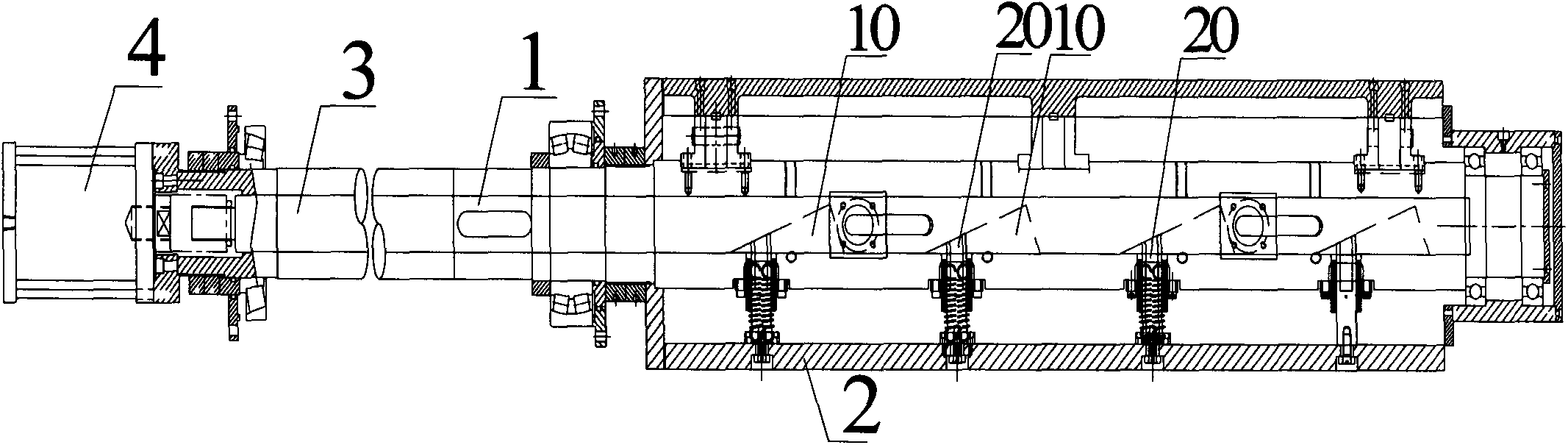

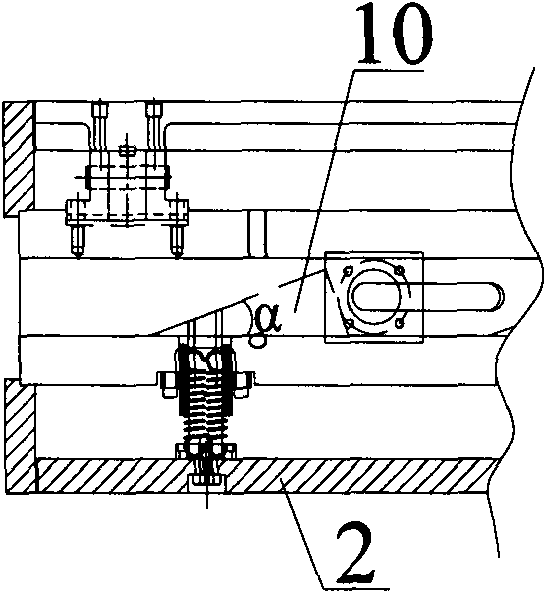

[0015] see figure 1 with figure 2 , Embodiment 1 of the present invention: a steel plate coiling device, including an oil cylinder 4, a telescopic shaft 3, a main shaft 1, and a blade 2, the blade 2 is fan-shaped, and the blade 2 is provided with four pieces, and the four fan-shaped blades 2 are combined into a cylindrical shape structure, the main shaft 1 is placed in the center of the cylindrical structure and extends out of the cylindrical structure, the telescopic shaft 3 is connected to the main shaft 1, and the telescopic shaft 3 is connected to the oil cylinder 4; the main shaft 1 is provided with a plurality of tapered grooves 10, and each blade A tapered bar 20 is provided at the position corresponding to the tapered groove 10 on the 2, and the tapered bar 20 can be embedded in the tapered groove 10 and can move along the slope of the tapered groove 10.

[0016] In this embodiment, the end of the tapered strip 20 in contact with the tapered groove 10 is provided wit...

Embodiment 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in this embodiment, the upper inner wall of the tapered groove 10 and the horizontal plane where the axis of the main shaft 1 is located form an angle α, and the degree of α is 20°; The degree of inclination provided on the end of the tapered strip 20 in contact with the 10 tapered grooves is 20°.

Embodiment 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in this embodiment, the upper inner wall of the tapered groove 10 and the horizontal plane where the axis of the main shaft 1 is located form an angle α, and the degree of α is 30°; The degree of inclination provided on the end of the tapered strip 20 in contact with the tapered groove 10 is 30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com