Native organic refuse integrated processing multifunctional all-in-one machine

An organic waste, multi-functional technology, applied in liquid separation, solid waste removal, chemical instruments and methods, etc., can solve the problem of oil-rich wastewater not being comprehensively treated and utilized, and achieve the effect of rapid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with accompanying drawing:

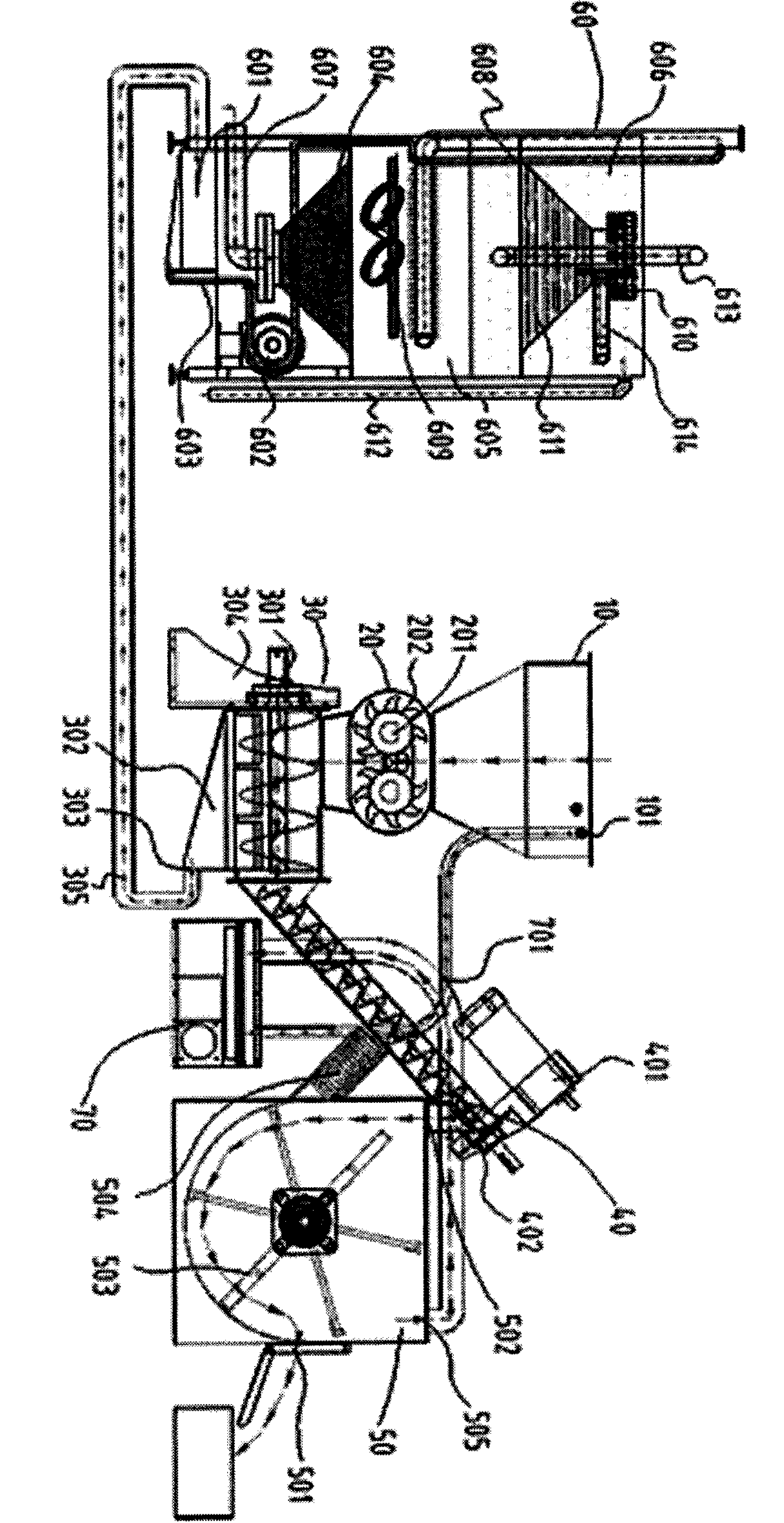

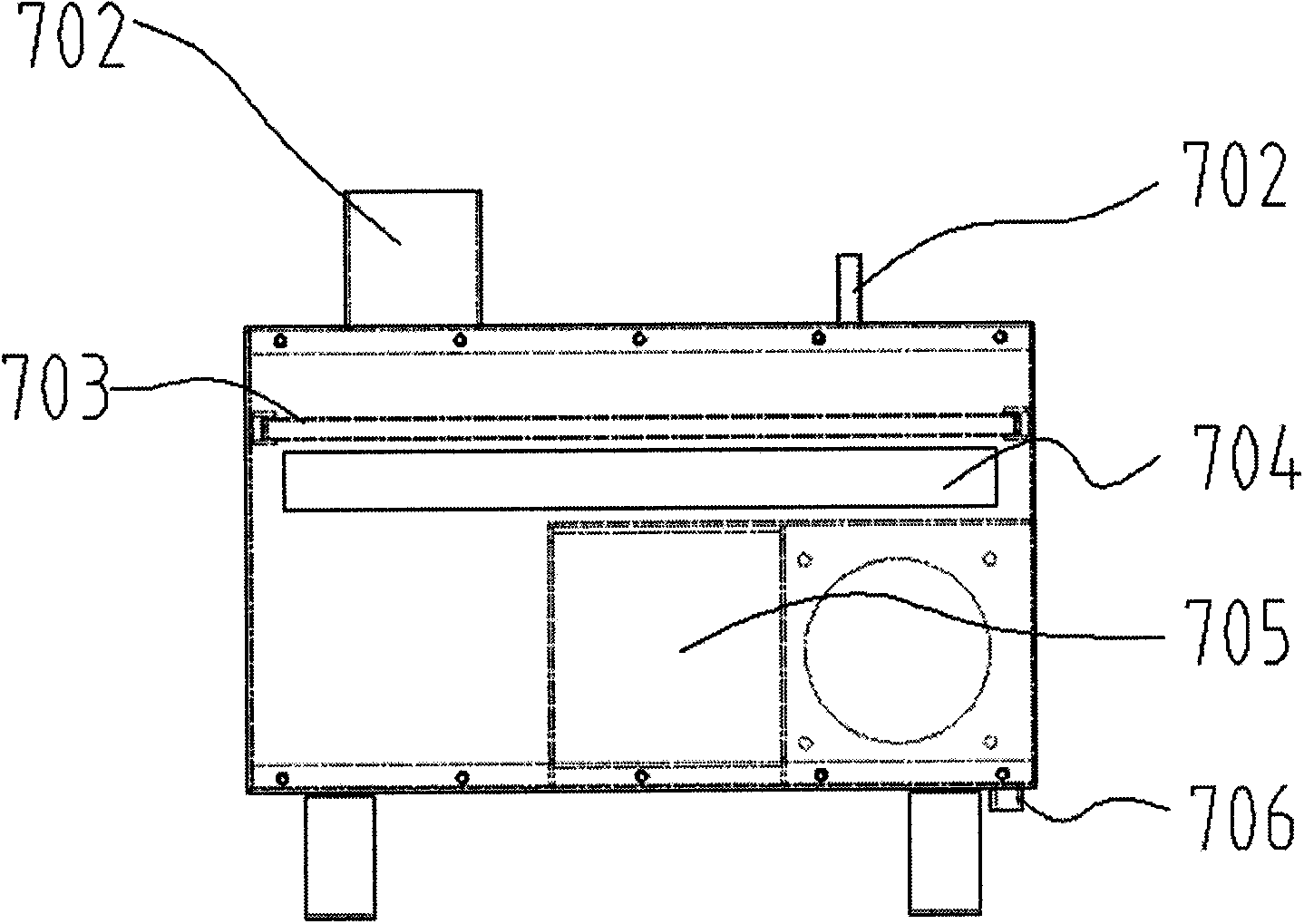

[0017] Such as figure 1 , 2 As shown in , 3: the original organic waste integrated processing multi-function machine, including the feeding box 10, the crushing mechanism 20, the dehydration mechanism 30, the lifting mechanism 40 and the drying mechanism 50 connected in sequence, the dehydration mechanism passes the waste generated in the process of processing through the pipeline The sewage is sent to the oil-water separation device 60, and the deodorizing mechanism 70 is also connected to the feed box and the drying mechanism.

[0018] Two groups of crushing knives 202 are fixed on the machine shaft 201 in the casing of the crushing mechanism 20. The crushing knives are divided into active knives and driven knives.

[0019] A shaftless spiral blade 301 is arranged in the housing of the dehydration mechanism 30, and an inclined water storage tank 302 and a water outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com