Precise Positioning Control Method of DC Motor Type Electric Push Rod

A technology of electric push rods and DC motors, applied in the field of control, can solve problems such as inability to realize positioning control, and achieve the effect of low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

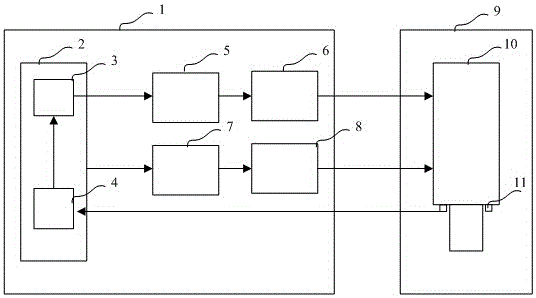

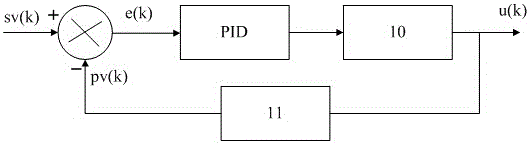

[0017] figure 1 It is a structural composition of a DC motor closed-loop control for an electric push rod. In the entire closed-loop control system, it includes: an electric push rod controller 1 and an electric push rod 9 . The electric push rod controller 1 includes a main control module 2 and a peripheral circuit module, the peripheral circuit module includes a PWM signal amplifier 5, a field effect transistor 6, a current drive chip 7 and a double-open double-throw relay 8, etc., and the main control module 2 includes a PID module 3 and A / D module 4, etc., the electric push rod 9 includes a DC motor 10 and a Hall sensor 11, etc. After the PID module 3 calculates according to the PID algorithm, it sends out PWM pulses, and after being amplified by the PWM signal amplifier 5, it drives the FET 6 to change the driving current of the DC motor 10 of the electric push rod 9, thereby realizing the control of the speed of the DC motor 10; The control module 2 outputs a TTL level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com