Plastic-aluminum film packed cylindrical lithium ion battery and making method thereof

A lithium-ion battery and aluminum-plastic film technology, which is applied in the field of lithium-ion batteries, can solve the problem of unreasonable placement of airbags for aluminum-plastic film packaging cylindrical lithium-ion batteries, affecting the size design of lithium-ion electronics, and punching holes in aluminum-plastic film packaging, etc. problems, to shorten production time, improve flexibility, and avoid air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

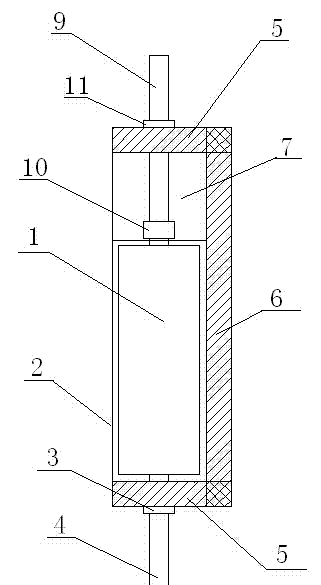

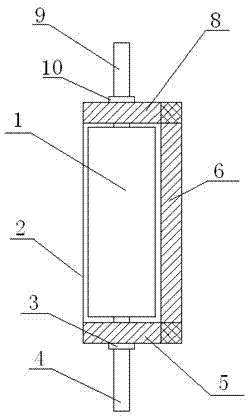

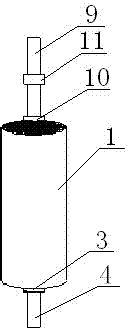

[0026] Such as Figure 1 to Figure 4 A cylindrical lithium-ion battery packaged in aluminum-plastic film is shown, which includes a cylindrical battery core 1 formed by winding a positive electrode sheet, a negative electrode sheet, and a separator. The battery cell 1 is arranged in an aluminum-plastic film bag 2, and the battery cell The two ends of 1 are the positive ear 4 and the negative ear 9 respectively, and the negative ear 9 is provided with two ear glues, that is, the first ear glue 10 and the second ear glue 11, and the second ear glue 11 is located on the negative ear 9 The distance between the first pole ear glue 10 and the second pole ear glue 11 is not less than the height of the airbag 7, and the positive pole ear 4 is provided with a pole ear glue, that is, the third pole ear glue 3 and the second pole ear glue 3. The ear gel 11 and the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com