Testing method for testing density of coating

A testing method and coating technology, which can be used in measuring devices, specific gravity measurement, instruments, etc., can solve the problem that the coating density cannot be directly measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

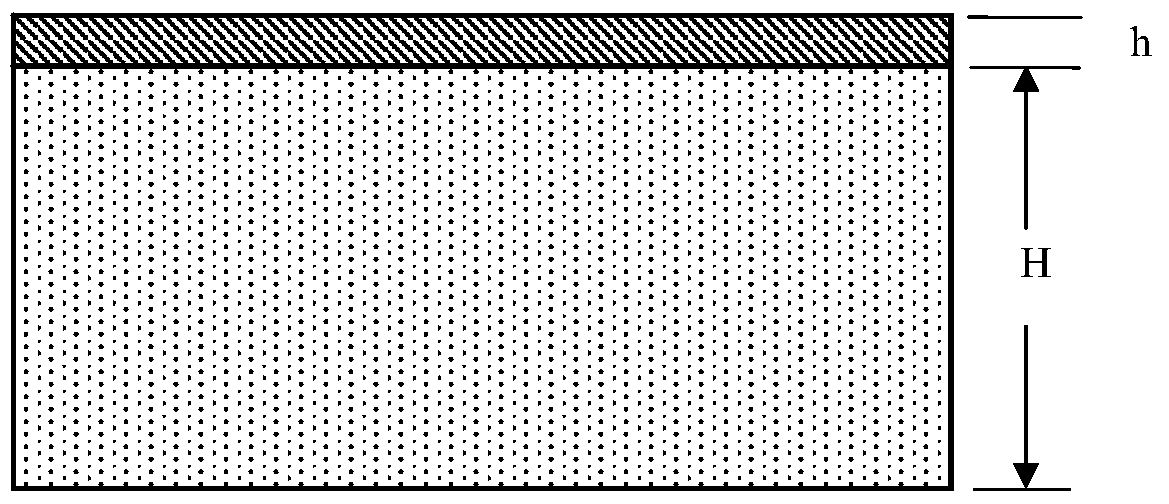

[0082] Embodiment 1: the test of monolayer ceramic coating density

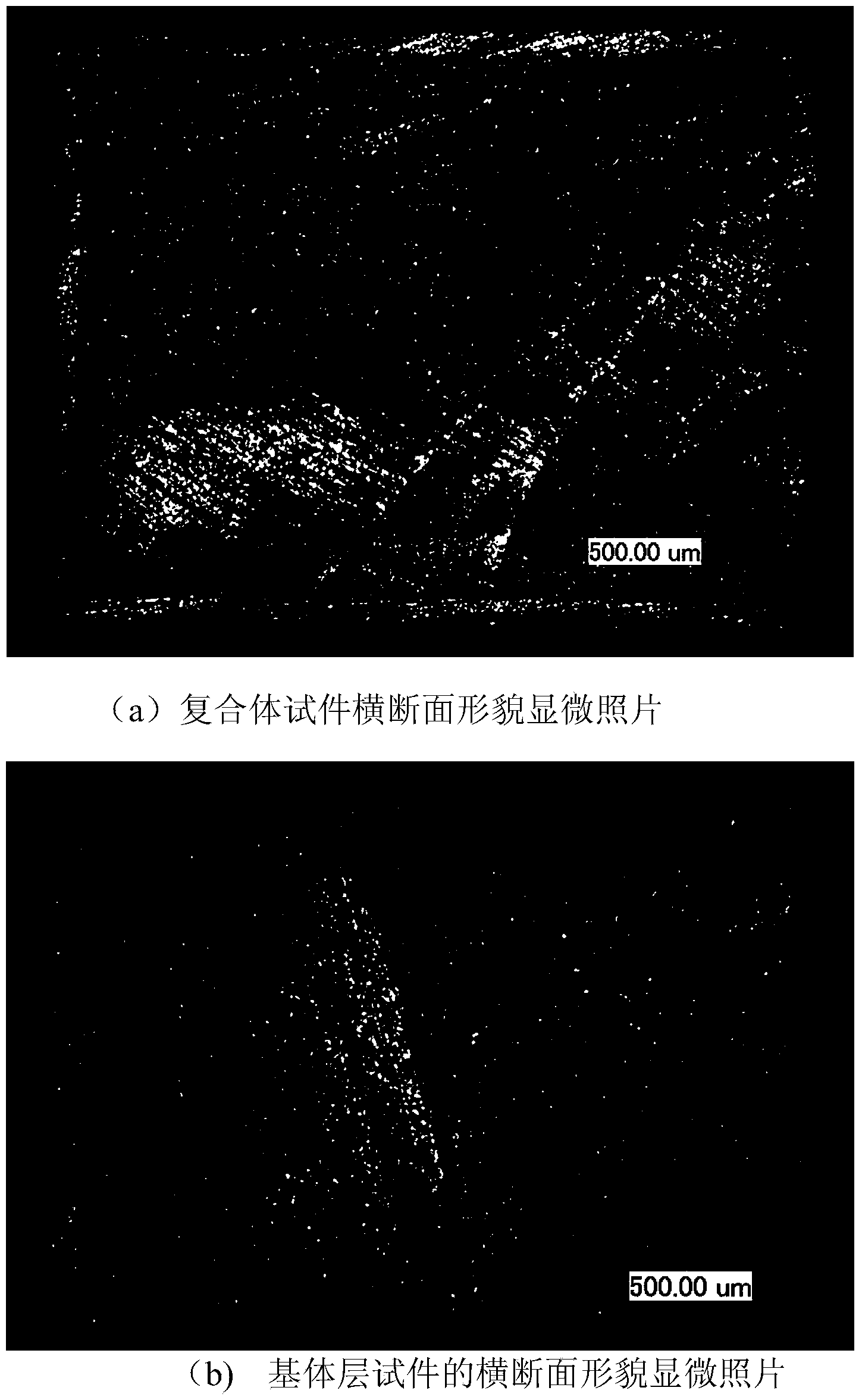

[0083] Specimen: a composite specimen of a chemical vapor deposited silicon carbide film on the surface of a graphite matrix layer.

[0084] experiment procedure:

[0085] 1) Measure and calculate the dry weight of the composite specimen and density Refer to the national standard GB / T25995-2010 to measure the dry weight of the composite specimen calculated density ρ ‾ = 2.0882 g / cm 3 ;

[0086] 2) Measure and calculate the dry weight of the substrate layer specimen and density Grind off the coating on the composite test piece to form a base layer test piece, and use the same method as step 1) to measure the dry weight m of the base layer test piece s =0.7451g, calculate the density ρ of the substrate layer specimen s =1.8539g / cm 3 ;

[0087] 3) Calculate the densi...

Embodiment 2

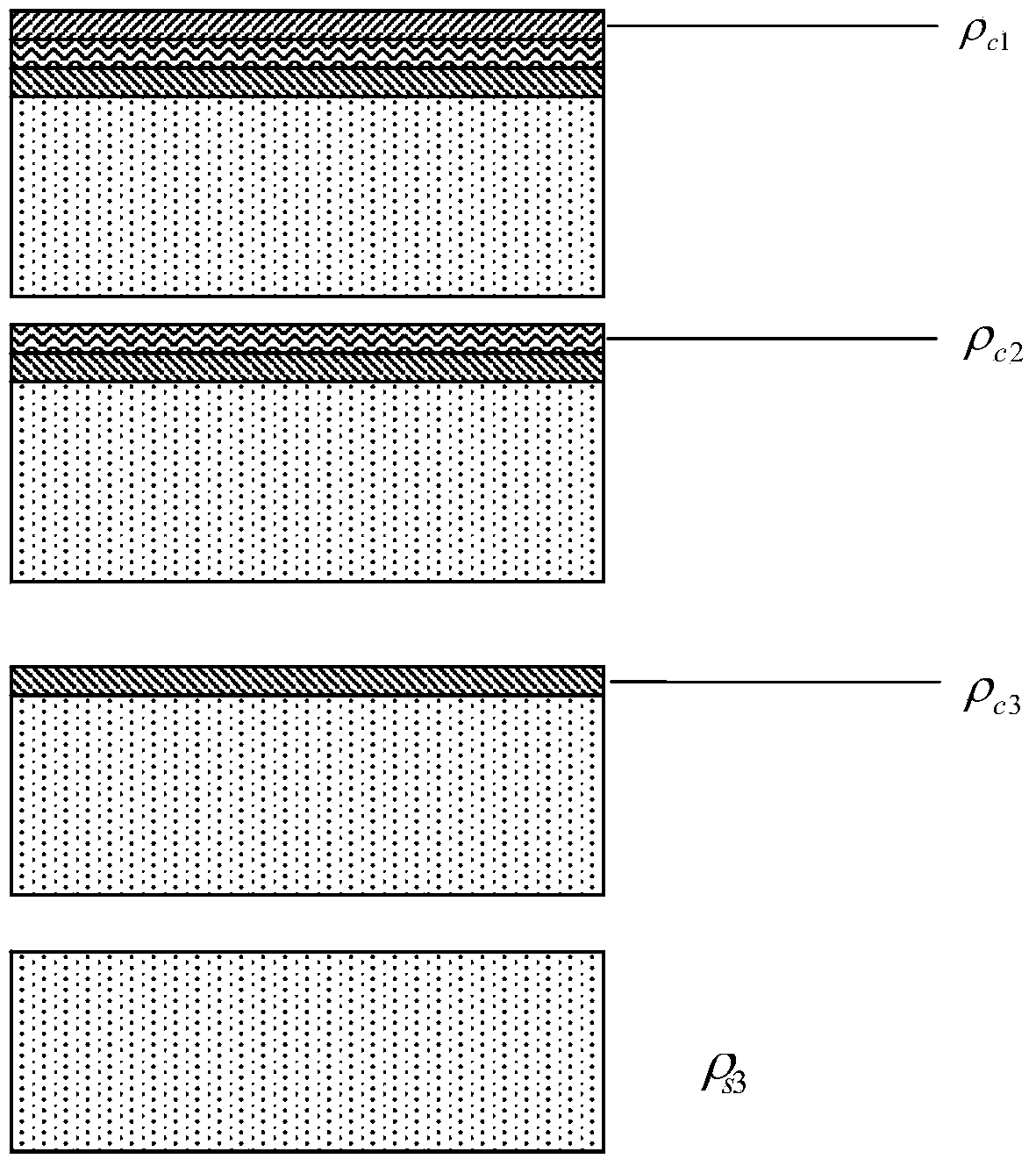

[0090] Embodiment 2: the test of multi-coat ceramic coating density

[0091] Test piece: carbon steel substrate thermal barrier coating test piece (the first layer of coating material is an anti-oxidation coating, the second layer of coating material is a zirconia coating, and the third layer of coating material is a nickel-chromium alloy coating) .

[0092] experiment procedure:

[0093] According to the same method as the above-mentioned single-coat density test, first test the dry weight and density of the initial test piece, grind off the set coating, and then test the dry weight of the remaining test piece (the remaining test piece is regarded as the base layer). Weight and density, put the relevant values into the formula (8) to calculate the density of the worn-off coating, then wear off the second layer of coating, then test the dry weight and density of the remaining specimen and calculate the density of the worn-off layer, and then By analogy, the test results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dry weight | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com