Installation method of comprehensive mechanized filling, coal mining and open-off cutting equipment

A comprehensive mechanized and filling coal mining technology, which is applied to mining equipment, filling materials, safety devices, etc., can solve the problems that the cutting equipment affects the production and efficiency of the working face, and the installation space of the equipment behind the cutting is insufficient and cannot be realized. Achieve the effects of wide practicability, reduced impact, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

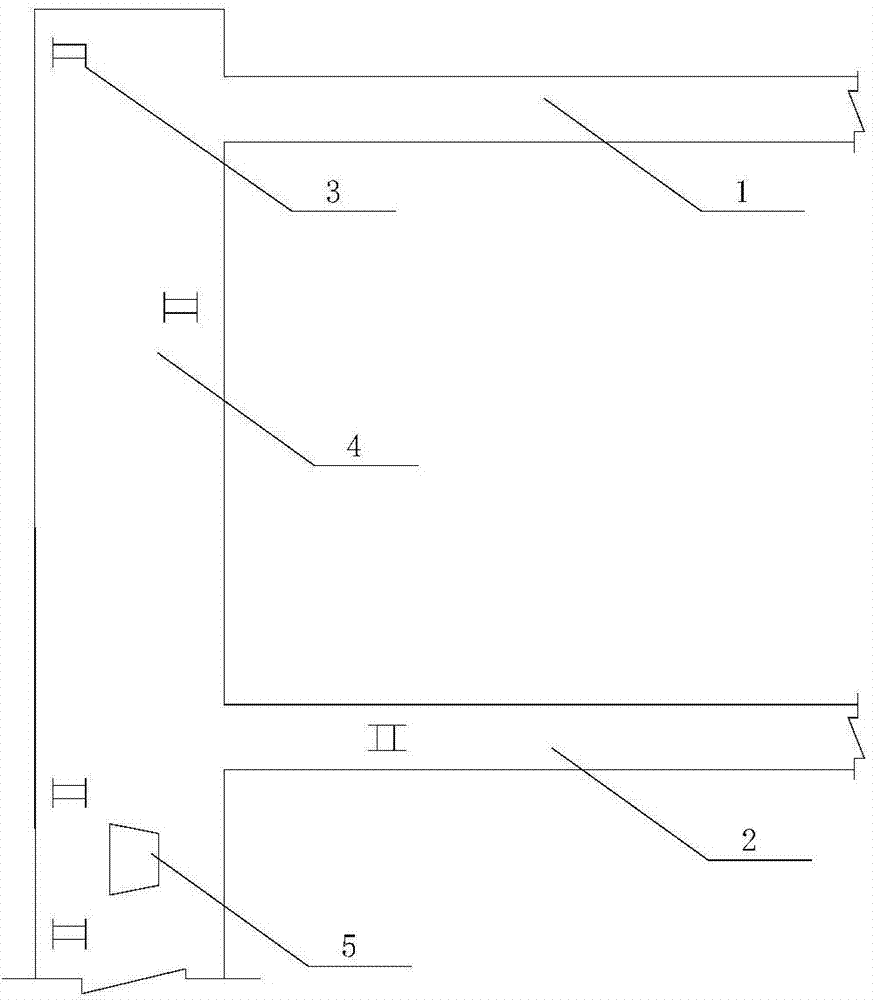

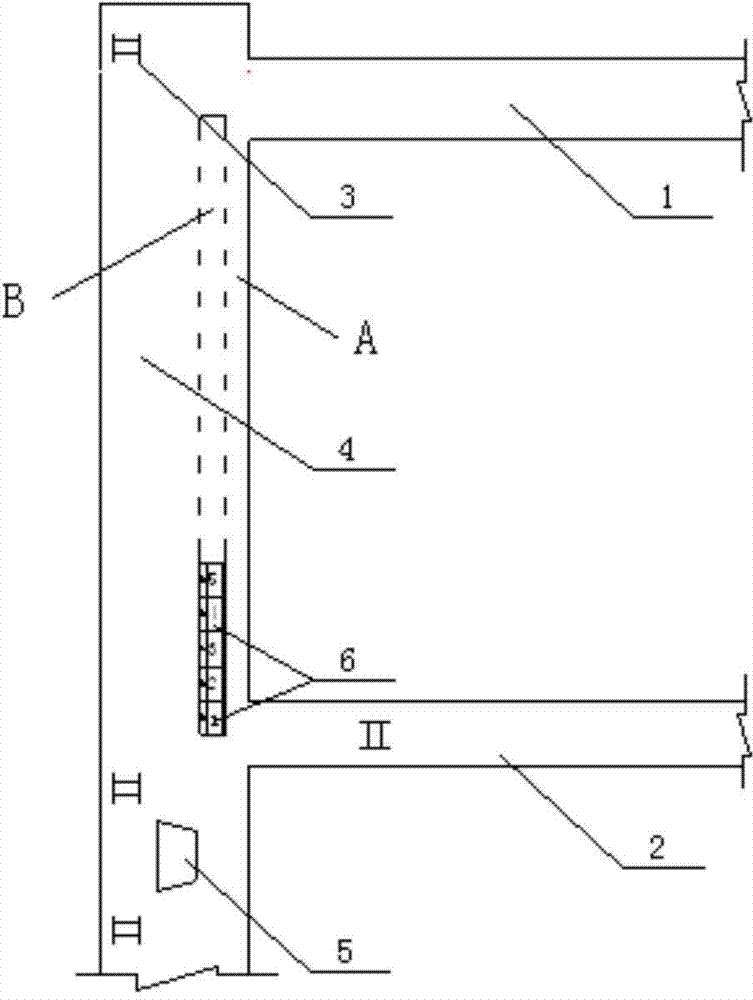

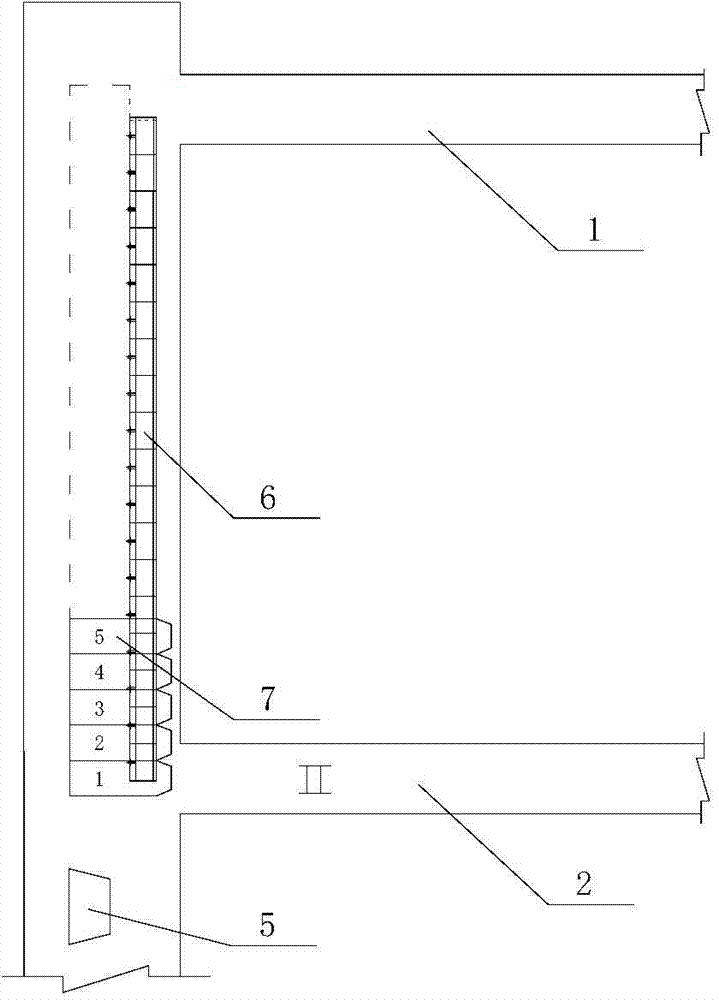

[0045] see Figure 8 , an installation method of comprehensive mechanized filling coal mining hole cutting equipment, the main operation and installation steps are as follows:

[0046] Step S11, first, according to the actual width and height of the section of the cut hole in the mine, carry out the bolt and anchor cable support for the cut hole;

[0047] Step S12, after opening the cut hole and completing the cut hole support operation, lay the first track on the side A of the coal wall; after the large part car of the scraper conveyor 6 enters the assembly room 5, use the winch 3 to move the large part Lift the car to the installation site, and install the various components of the scraper conveyor 6 along the first track;

[0048] Step S13, after the scraper conveyor 6 is installed, a second track is laid on the side of the goaf B, and the working surface support 7 is transported to the assembly room 5 for assembly;

[0049] Step S14, after the assembly of the working sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com