A vertical high-efficiency thread trimmer

A thread-end, high-efficiency technology, applied in the direction of fabric surface trimming, textile and papermaking, etc., can solve the problem of low processing efficiency of thread suction heads, and achieve the effect of good cutting effect, easy promotion and large adsorption force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

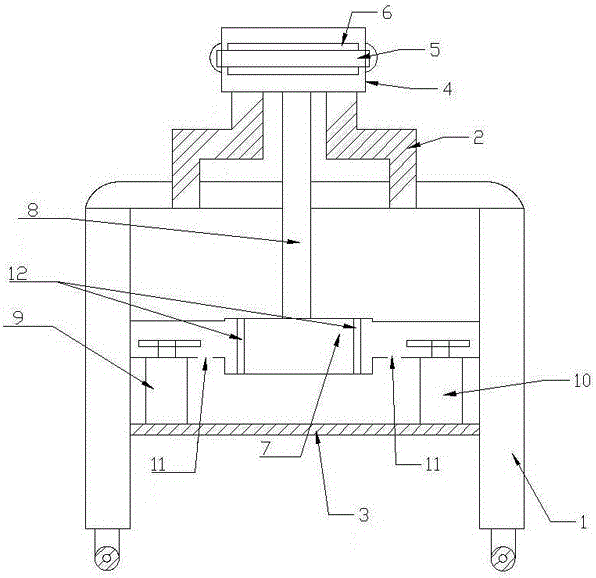

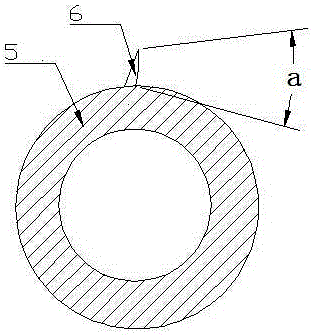

[0022] further as figure 1 As shown, the first centrifugal motor 9 and the second centrifugal motor 10 are turned on to carry out the ventilation operation (entered by the thread trimmer box 4 and flow out through the exhaust port 11), and then the rotating shaft 5 driving motor (not marked) is turned on to drive the rotating shaft 5 and The cutting knife 6 installed on the top rotates rapidly. When the clothing is close, the strong adsorption force will suck the excess thread ends on the clothing into the thread trimming box 4, and the rotating shaft 5 and the cutting knife 6 installed in the thread cutting box 4 quickly carry out the suction of the thread ends. , Precise cutting, the cut thread ends enter the thread end collection box 7 from the connecting pipe 8 under the left and right of the suction to complete the thread cutting operation, and the filter baffle plate 12 installed in it prevents the existing ones from entering the first centrifugal motor 9 and the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com