Biodegradable antibacterial composite fibers and preparation method thereof

A composite fiber and mixed solvent technology, applied in the field of materials science, can solve the problems of high infection probability, poor patient treatment experience, and large uncertainty, and achieve good biological safety, prevent skin ulcer infection, and enhance affinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

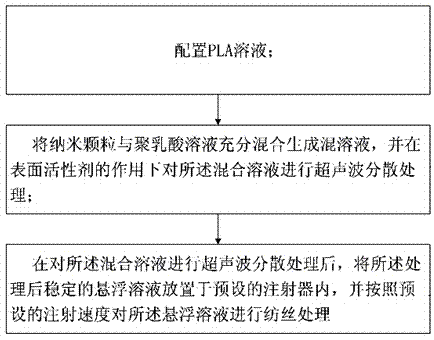

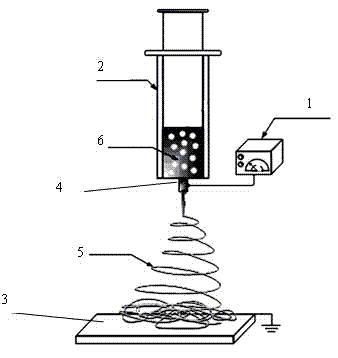

[0036] Such as figure 1 Shown, a kind of preparation method of degradable antibacterial composite fiber comprises the steps:

[0037] 1) Prepare PLA solution;

[0038] Use an electronic balance to measure 12 mg of PLA solid particles and pour them into brown jars, add 10 ml of mixed solvent, and place them on a magnetic stirrer at 25°C until the solids are completely dissolved. The molecular weight of polylactic acid is 200,000Da, and the mixed solvent is dichloromethane:N,N-dimethylformamide mixed at a ratio of 1:1.

[0039] 2) Fully mix the nanoparticles and the polylactic acid solution to form a mixed solution, and perform ultrasonic dispersion treatment on the mixed solution under the action of a surfactant;

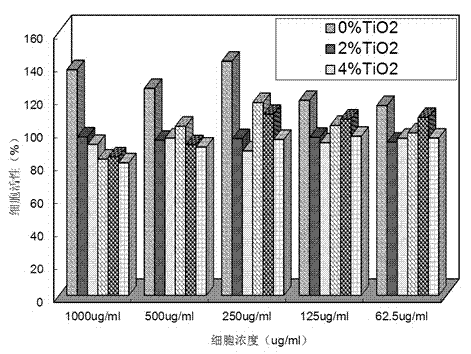

[0040] The parameters are as follows: the content of nanoparticles is respectively: 2%, 4%, 6%, 8% and 10% of the mass of polylactic acid. Surfactant: Tween Tween60 (adapted to nano-ZnO system) - 12% of the mass of ZnO; Tween Tween80 (adapted to nano-TiO 2 system...

Embodiment 2

[0046] Example 2 Test the suspension stability of nano ZnO

[0047] The suspension stability study results of ZnO / PLA solutions with Tween 60 and Tween 80 as surfactants are shown in Table 3, and Table 3 can be used to show that the content and type of surfactants affect the ZnO sedimentation situation, where, ( ×) means no sedimentation or stratification within the observation time;

[0048] (√) indicates that subsidence or stratification has occurred within the observation time;.

[0049] Table 1

[0050]

[0051] In the above table, 3 groups of well-mixed and non-stratified formulations can be selected for subsequent TEM tests. The test results are shown in Table 2, and Table 2 shows the TEM observation formulations.

[0052] type Determination of content Ultrasound time Tween60 12% 15min Tween60 12% 30min Tween80 8% 60min

Embodiment 3

[0053] Example 3 to nano TiO 2 Suspension Stability Tested

[0054] Taking Table 3 as an example, the embodiment of the present invention uses 12% PLA solution as the dispersion matrix, selects the compound system of dichloromethane and N,N-dimethylformamide (1:1) as the solvent, and mixes a certain amount of Nano-TiO 2 After being placed in the solution for a certain period of ultrasonic dispersion, the settling time of the nanoparticles in the PLA solution was observed. In this experiment, nano-TiO 2 Stable suspension in PLA solution for 4 hours as a reference basis and evaluation standard. The experimental results are shown in Table 3, and Table 3 is used to represent the effect of different surfactant types and contents on the nano-TiO 2 Influence of suspension stability, nano-TiO in the table 2 The suspension stability observation time is 240min.

[0055] table 3

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com