Charging device and method for multielement compound polycrystal material dual-temperature-region synthesis

A charging device and compound technology, applied in chemical instruments and methods, post-processing devices, crystal growth and other directions, can solve the problems of high synthesis device, difficulty in vacuuming, and high production cost, reduce time and difficulty, simplify The effect of loading link and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

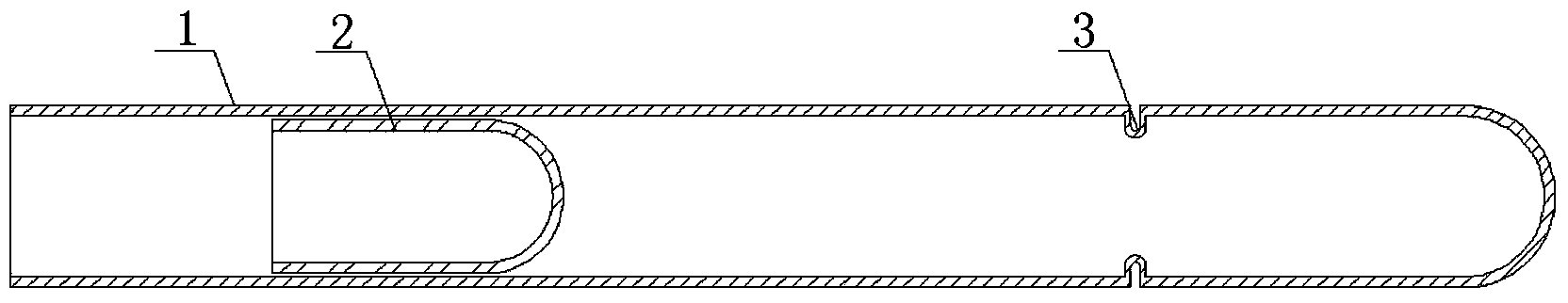

[0032] 1) Weigh the single substance of the raw material of the multi-component compound to be synthesized according to the proportion, and then put the simple substance that will not generate high vapor pressure during synthesis into the charging member of the charging device for the dual-temperature zone synthesis of the multi-component compound polycrystalline material bottom;

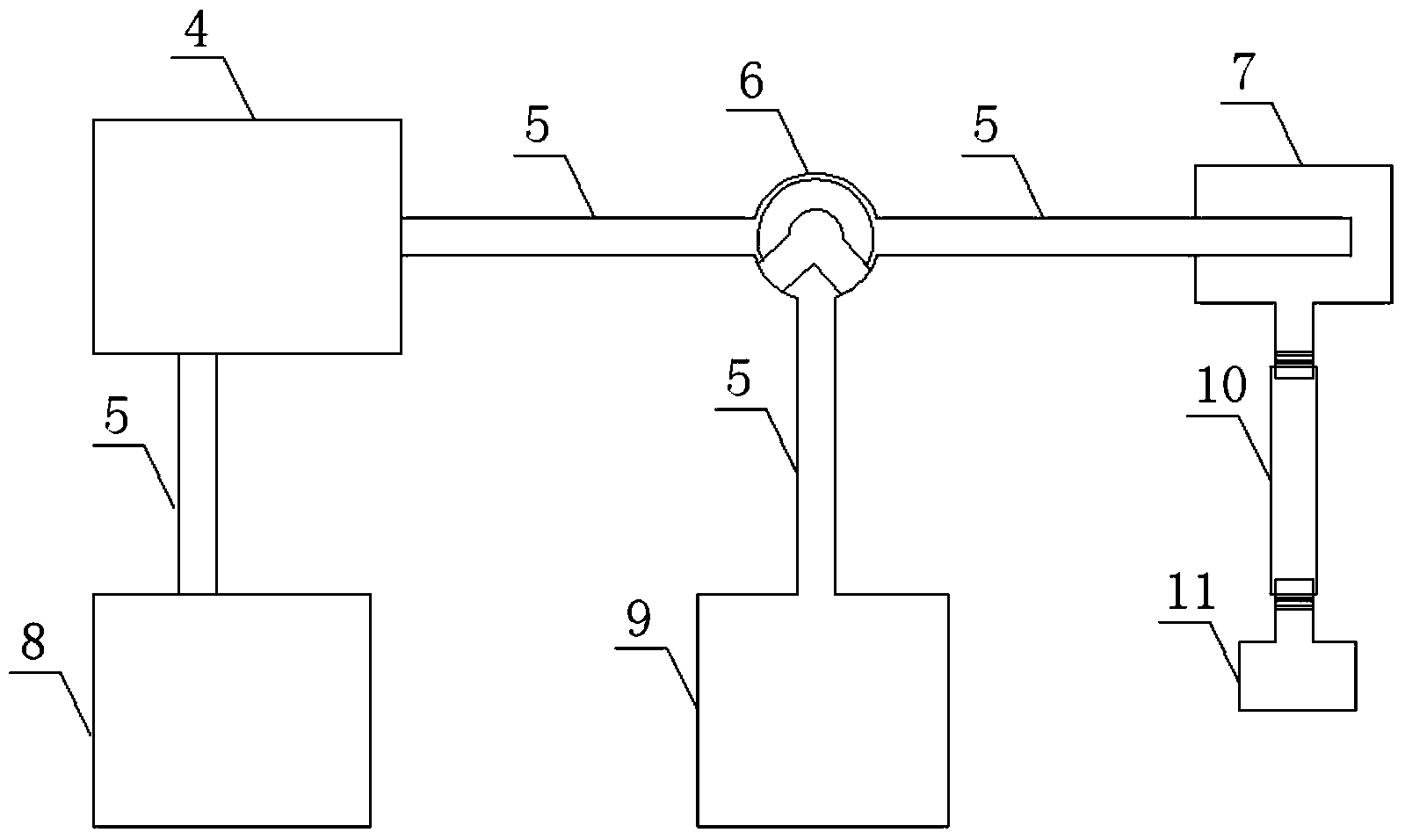

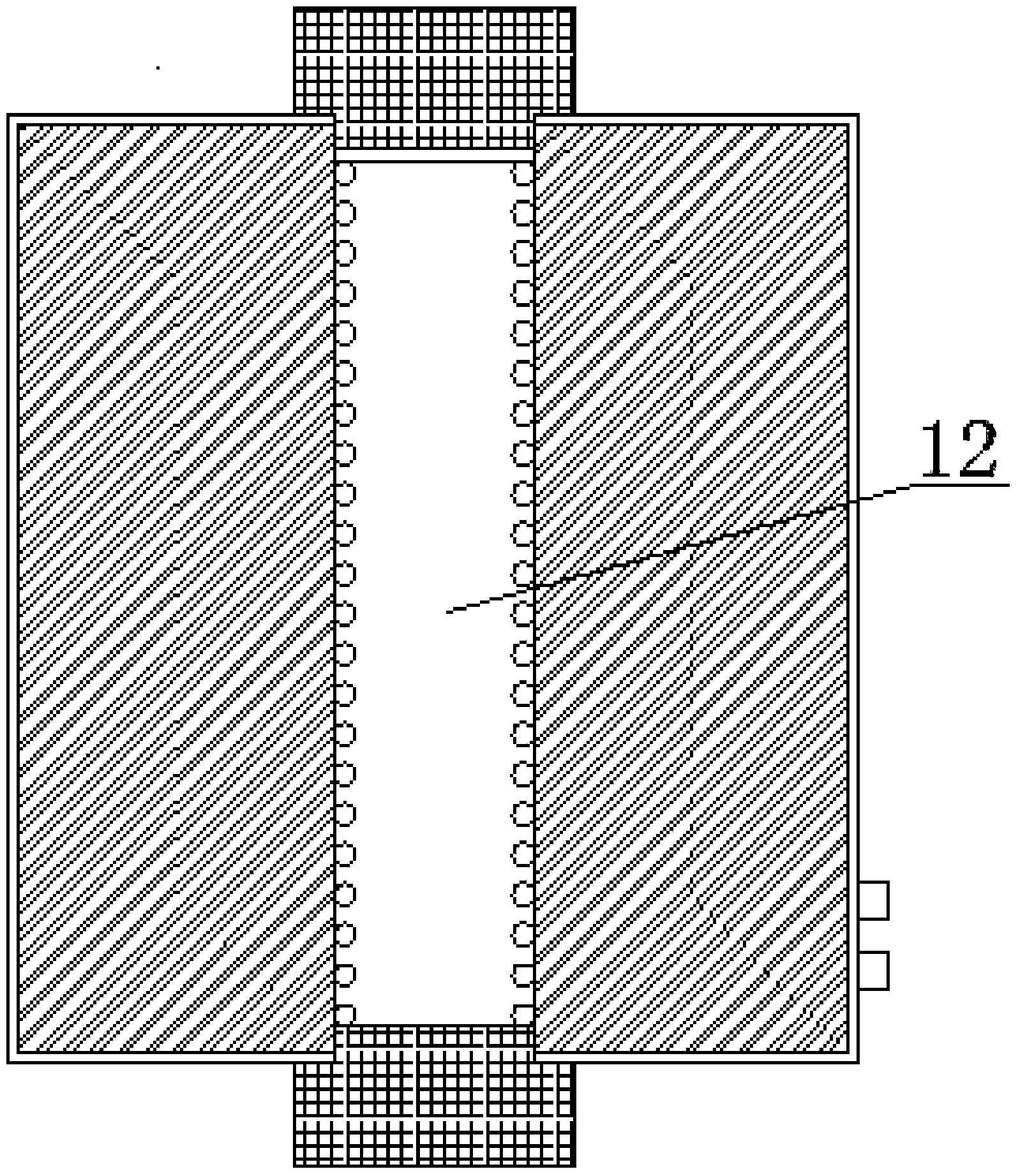

[0033]2) Connect the charging component loaded with the single substance to the quick conversion interface 11 of the vacuum sealing component with a three-way ventilation valve, and connect the quick conversion interface 11 to the backing vacuum pump 8 and the molecular pump through the three-way ventilation valve 6 After the air path between 4, open the front vacuum pump 8 for vacuuming, when the vacuum degree reaches 1×10 -1 After Pa, the gas path between the quick conversion interface 11 and the high-purity argon bag 9 is connected through the three-way gas exchange valve 6, and the high-purity a...

Embodiment 2

[0040] 1) Weigh the single substance of the raw material of the multi-component compound to be synthesized according to the proportion, and then put the simple substance that will not generate high vapor pressure during synthesis into the charging member of the charging device for the dual-temperature zone synthesis of the multi-component compound polycrystalline material bottom;

[0041] 2) Connect the charging component loaded with the single substance to the quick conversion interface 11 of the vacuum sealing component with a three-way ventilation valve, and connect the quick conversion interface 11 to the backing vacuum pump 8 and the molecular pump through the three-way ventilation valve 6 After the air path between 4, turn on the front vacuum pump 8 to vacuumize, when the vacuum degree reaches 3×10 -1 After Pa, the gas path between the quick conversion interface 11 and the high-purity argon bag 9 is connected through the three-way gas exchange valve 6, and the high-purit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com