Drive control method and device of final dusting high-voltage motor of steel mill

A technology for secondary dust removal and electric motors, which is applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of scrapped electrical equipment, waste of costs, and the failure of high-voltage motors for secondary dust removal to operate normally, and achieve the effect of saving electric energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

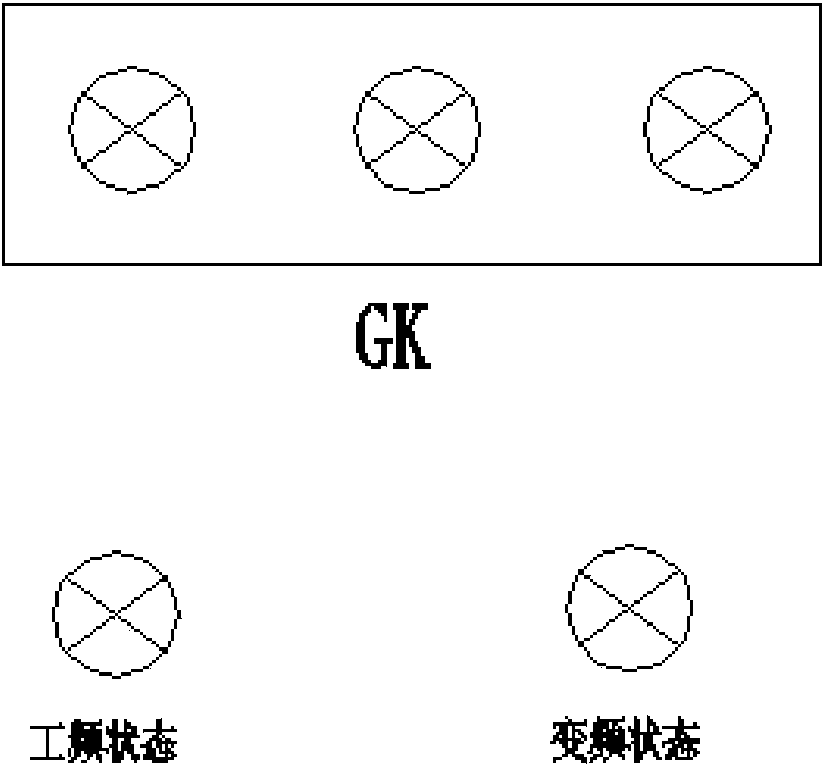

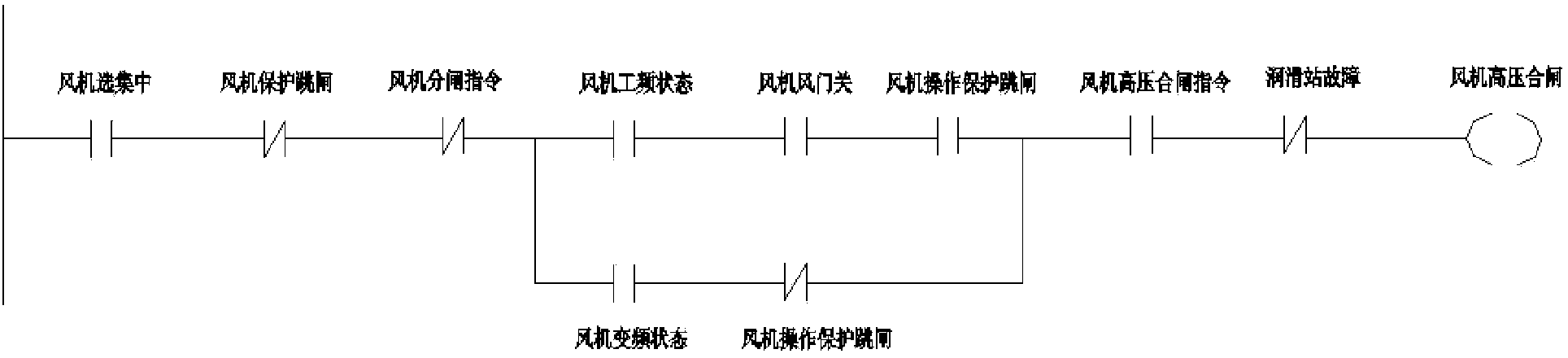

[0018] like figure 1 As shown, for the secondary dust removal high-voltage motor, in the inverter drive mode, through K 1 closed, K 2 Hit the frequency conversion position, namely K 2 The moving end of the inverter is connected to the outlet end of the inverter, and the QS 1 closed, QS 2 disconnected, and the secondary line of the motor is short-circuited. After the high-voltage power supply is closed, the inverter is in a ready state. The input line of the secondary dust removal high-voltage motor is connected to 10KV high voltage. After clicking on the start, the motor can run at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com