Tunnel scanning pass-through demagnetizer

A demagnetization machine and tunnel technology, applied to magnetic objects, electrical components, circuits, etc., can solve the problems of wasting manpower, low work efficiency, and increased labor intensity, and achieve the effects of eliminating residual magnetism of workpieces, increasing service life, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

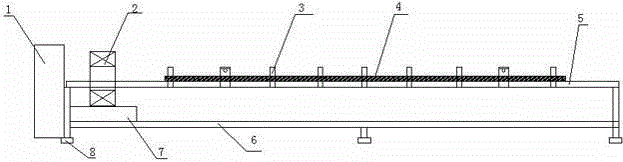

[0016] The present invention will be further described below in conjunction with the accompanying drawings:

[0017] refer to figure 1 As shown, a tunnel scanning pass-through demagnetization machine in Example 1 includes a bed, a control cabinet 1, the control cabinet 1 is at the front end of the bed, the bed includes a base 6, a material bridge 5, and a shock absorber 8 to avoid Vibration pad 8 is arranged on the bottom of base 6, and material bridge frame 5 is positioned at the top of base 6, and connects end to end with base 6, and material bridge frame 5 both sides is provided with anti-falling rib 3, and sports car 7 is installed on base 6, The base 6 and the sports car 7 are connected by guide rails, and the top of the sports car 7 is connected with the executive coil 2 through the support screw, which can be adjusted up and down. The inner layer of the executive coil 2 is a coil, and the outer layer is covered with an insulating shell. There is a frequency conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com