MEMS (micro-electromechanical system) methane sensor as well as application and preparation method thereof

A methane sensor, wet method, applied in material resistance and other directions, can solve the problems of high power consumption, short calibration time, and high price of infrared methane sensors, and achieve the effect of low power consumption and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

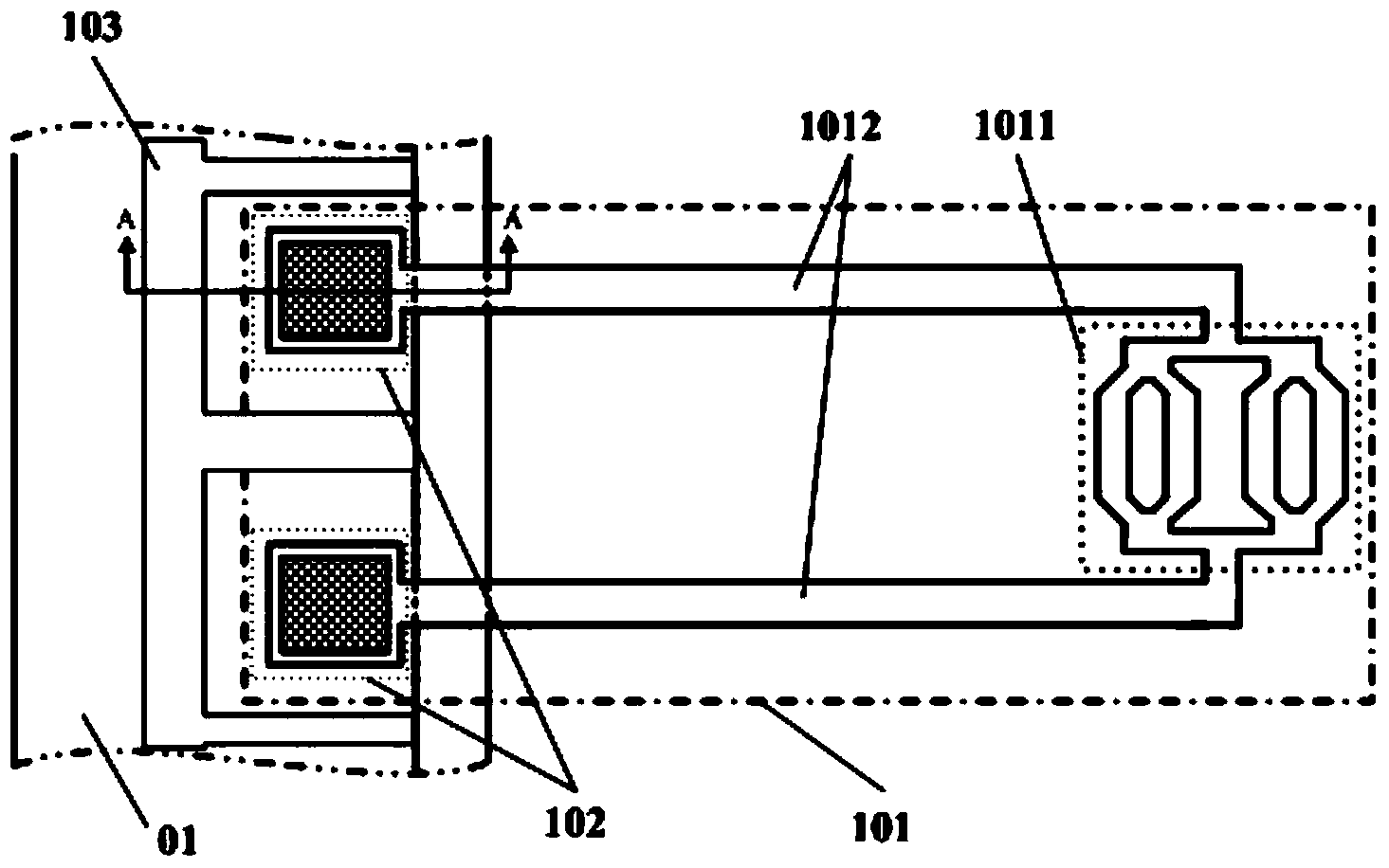

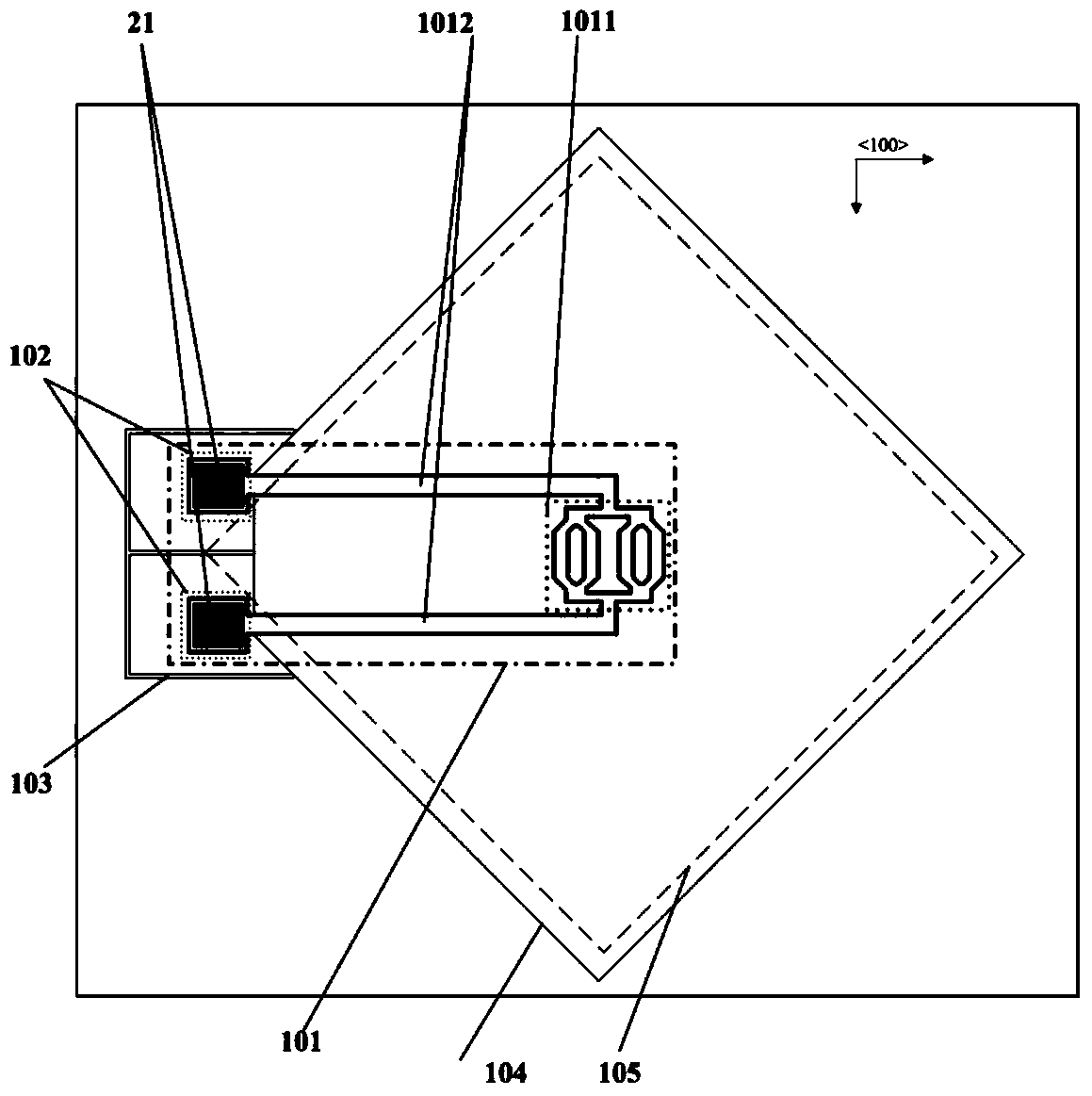

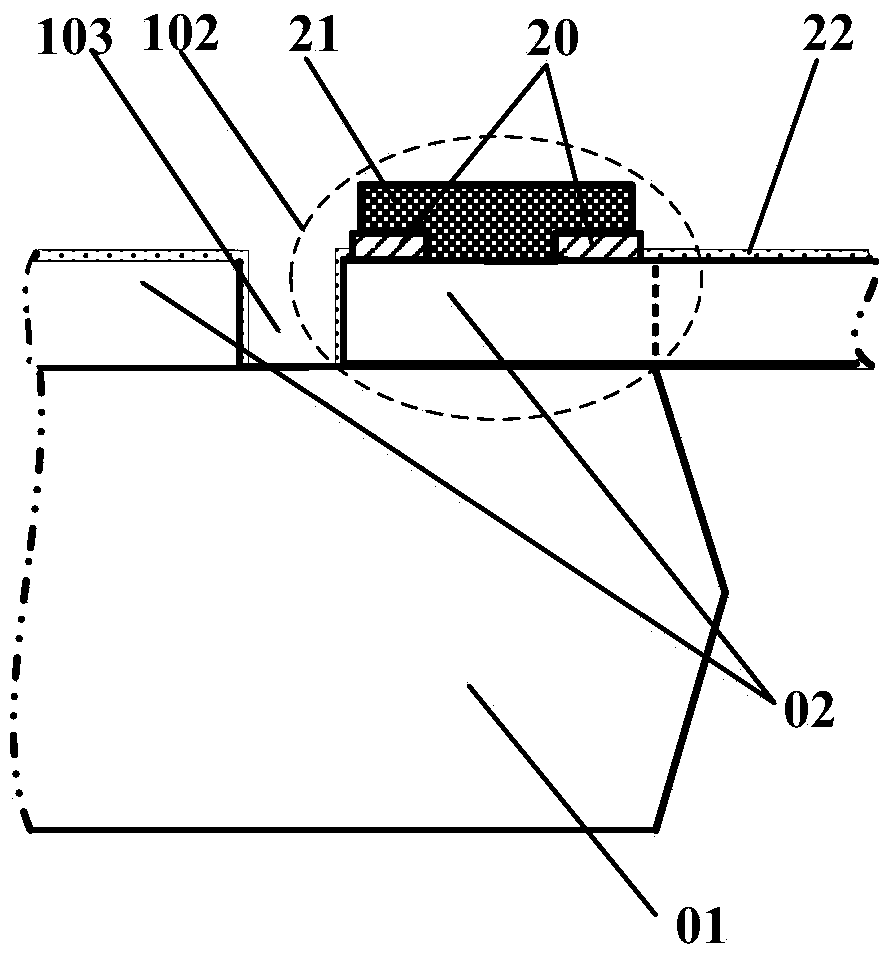

[0052] Such as figure 1 , figure 2 , image 3 As shown, the MEMS methane sensor of the present invention includes a P-type silicon substrate 01, and an N-type silicon 02 is arranged on the P-type silicon substrate 01; Element 101; the silicon heating element 101 includes two fixed ends 102, a silicon heater 1011, and two silicon cantilevers 1012; the length of the single silicon cantilever 1012 is at least 300um; one end of the single silicon cantilever 1012 is connected to the silicon heating The other end is connected to a fixed end 102 to provide electrical connection for the silicon heater 1011; the two silicon cantilevers 1012 are arranged in parallel and side by side, forming a U-shaped cantilever structure with the silicon heater 1011 as a whole, and the silicon heater 1011 Suspended in the air; the silicon heater 1011 of the silicon heating elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com