A vibration-insulating type composite-energy water heater

A composite energy, water heater technology, applied in solar collectors, water heaters/stoves, solar thermal energy, etc., can solve the problems of single energy source, inability to supply hot water and large vibration of water heaters, and achieve a single and smooth flow direction. Good heat exchange and vibration isolation effect, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

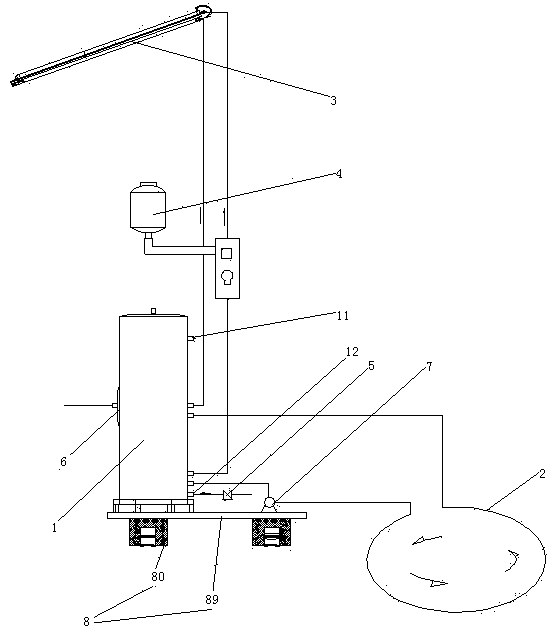

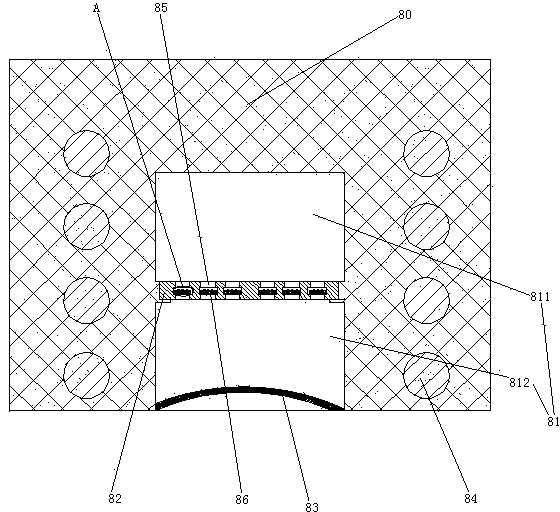

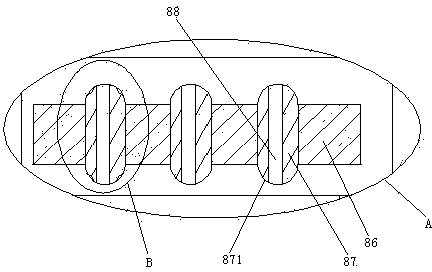

[0030] Embodiment one, see figure 1 , The shock-isolated composite energy water heater includes a water tank 1, a heating coil 2, a solar collector 3 and a shock-isolation frame 8.

[0031]The water tank 1 is also provided with a hot water outlet 11 and a cold water inlet 12 . A one-way valve 5 is installed in the cold water inlet 12 . The one-way valve 5 is opened toward the inside of the water tank 1 . An electric heater 6 is also provided in the water tank 1 . The electric heater 6 is used for heating the water in the water tank 1 .

[0032] Both ends of the heating coil 2 are connected with the water tank 1 . The heating coil 2 and the water tank 1 form a hot water circulation loop of the earth stove. A circulating water pump 7 is provided in the earth stove hot water circulation circuit.

[0033] The water inlet and outlet of the solar heat collector 3 are connected together with the water tank 1. The solar heat collector 3 and the water tank 1 form a solar hot wat...

Embodiment 2

[0039] Embodiment two, the difference with embodiment one is:

[0040] see Figure 5 , also includes oil replenishment mechanism 9.

[0041] see Image 6 , The circulating water pump 7 includes a pump casing 71 , a pump shaft 72 and a bearing 73 . The pump shaft 72 is rotatably connected in the pump housing 71 through a bearing 73 . The pump casing 71 is provided with an oil filling hole shaft hole 74 for oiling the bearing.

[0042] The oil replenishing mechanism 9 includes an oil storage tank 91 , an oil outlet channel 92 and a corrosive liquid storage tank 94 .

[0043] One end of the oil outlet passage 92 is provided with a filler nozzle 922 , and the other end is provided with an oil inlet bucket 921 . The filler nozzle 922 is butted together with the filler hole 74 . The oil inlet hopper 921 is located below the oil storage tank 91 . The filler nozzle 922 is lower than the oil storage tank 91 , that is, the oil in the oil outlet passage 92 can automatically flow i...

Embodiment 3

[0055] Embodiment three, see Figure 10 , the difference with the second embodiment is: the corrosive liquid storage tank 94 is provided with a wave-dissipating plate 941 floating on the corrosive liquid 97 in the corrosive liquid storage tank. The shell 951 passes through the wave breaking board 941 in a liftable manner along the up and down direction. The peripheral surface of the wave breaking plate 941 abuts against the side wall of the corrosive liquid storage tank 94 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com