Hole sealing method for coal bed gas drainage drill hole

A coal seam gas and hole sealing device technology, which is applied in the direction of gas discharge, earthwork drilling, sealing/seal, etc., can solve the problems of gas leakage at the orifice, poor sealing of drilling holes, and clogging of coal dust, so as to improve the sealing hole depth, improve gas drainage rate, and avoid the effect of lax hole sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

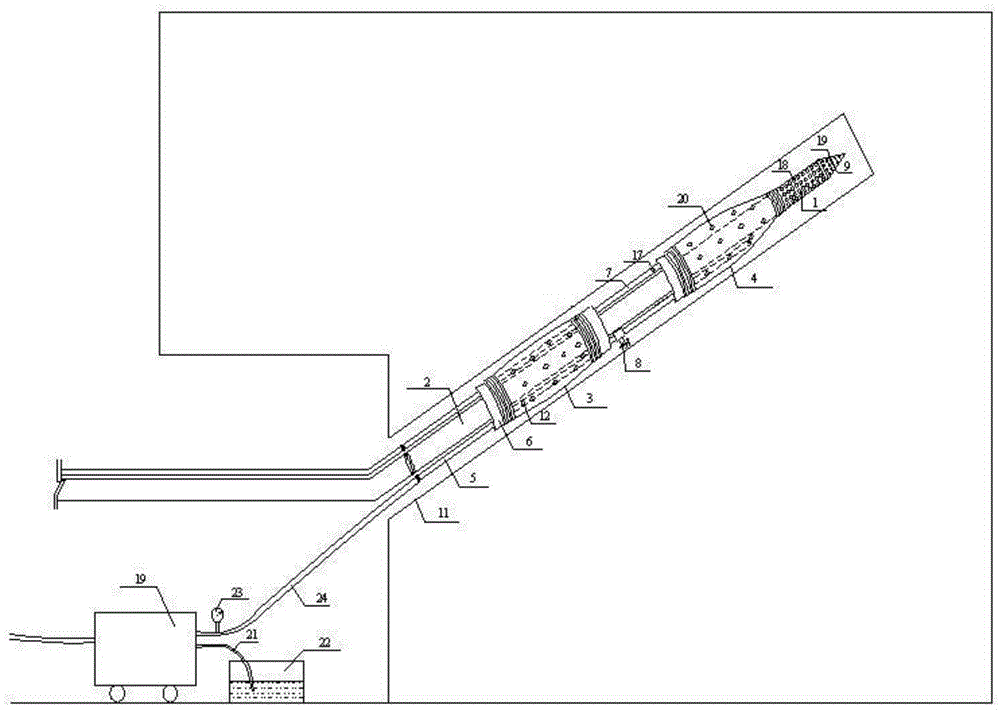

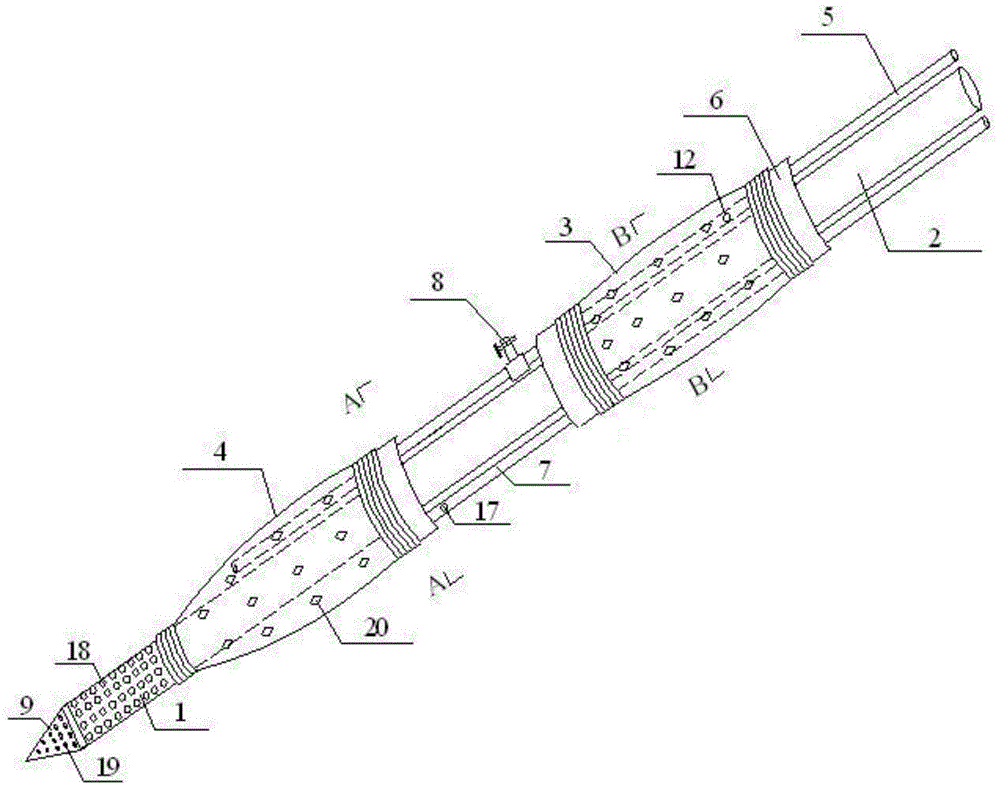

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

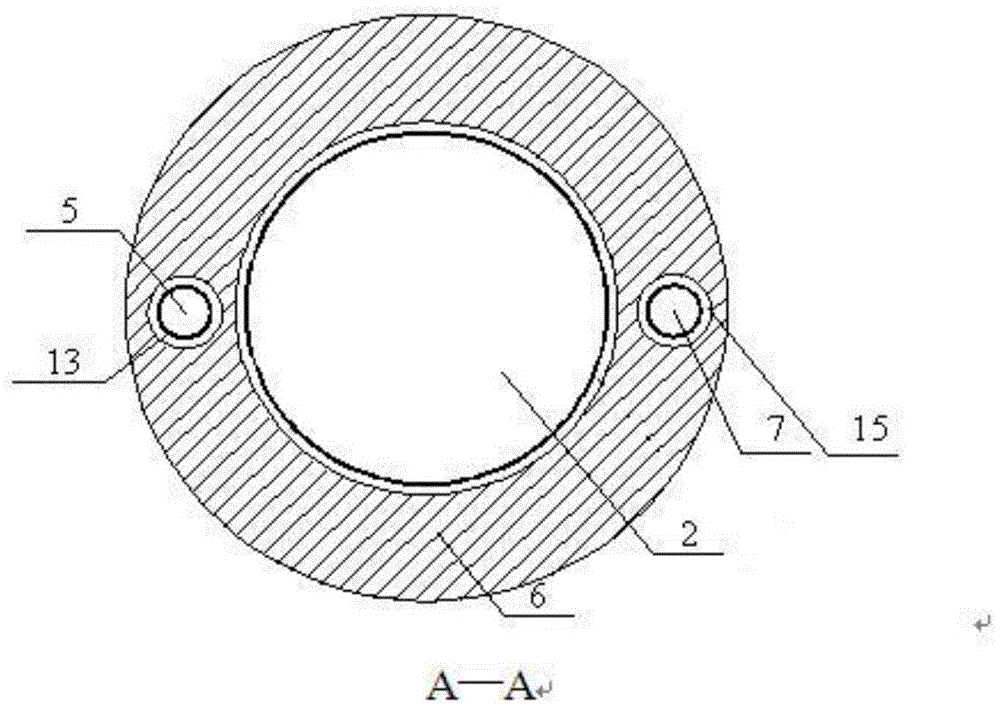

[0025] as attached figure 2 , 3 As shown in and 4, the drilling radial hole sealer involved in the present invention includes a coupling piece 9, a main suction pipe 1, an auxiliary suction pipe 2, a rear pocket 4, a front pocket 3, a grouting pipe 5, and a grout return Pipe 7 and blasting valve 8, one end of the main drawing pipe 1 is connected to the coupling 9, the length of the main drawing pipe 1 is 3-10m, the outer diameter and inner diameter are 50mm and 48mm respectively, the pipe wall of the main drawing pipe 1 Circular holes 18 are distributed around, the connector 9 is in the shape of a cone, and the surface of the connector 9 is distributed with oval holes 19. The other end of the main suction pipe 1 is connected to the secondary suction pipe 2, and the secondary suction pipe 2 The length is 5-20m, and the outer diameter and inner diameter are 50mm and 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com