A reticulated box-shaped component for forming holes in cast-in-place hollow floor

A technology of hollow floor and mesh box, which is applied in the direction of building components, floor slabs, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

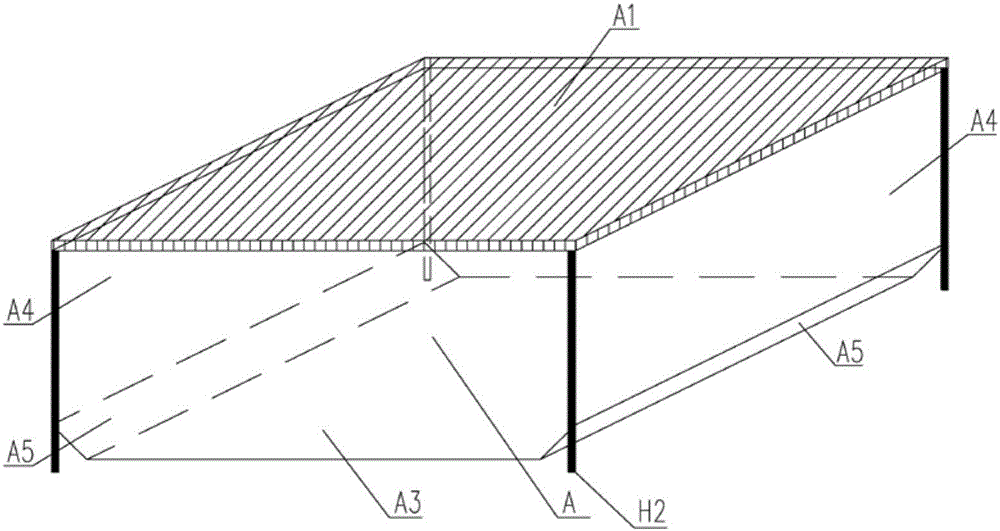

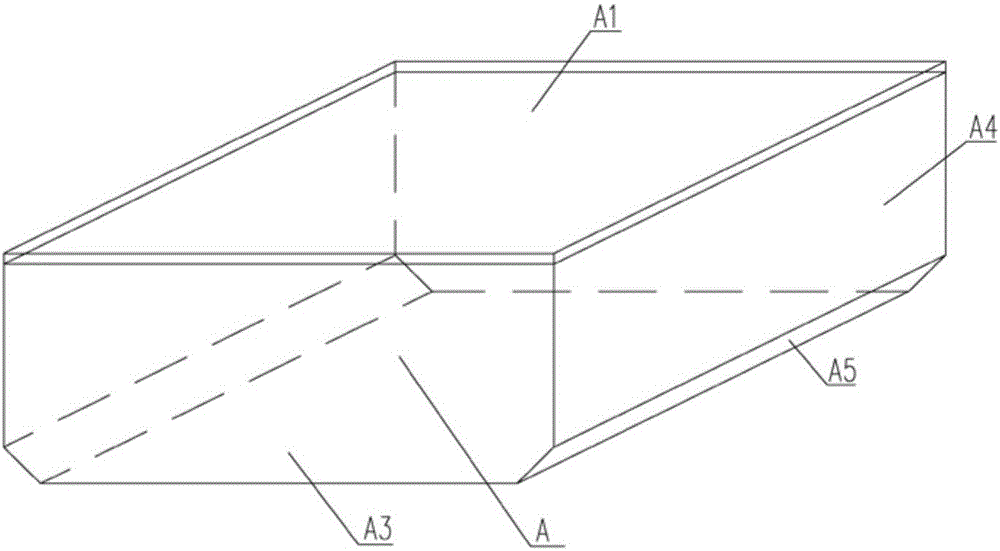

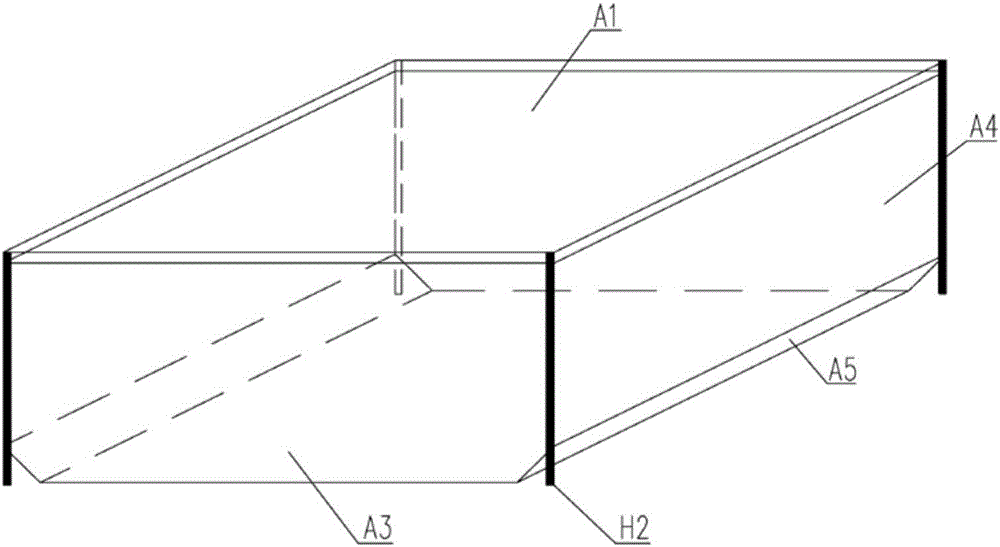

[0029] The invention will be further described below in conjunction with the accompanying drawings.

[0030] A reticulated box-shaped component for forming holes in cast-in-place hollow floors according to the present invention uses special mechanical equipment and molds to manufacture a reticulated body A2 comprising a reticulated plate A21, reinforcing ribs A22 and connecting nets A23. The reinforcing rib is made along the length direction, and the thin steel plate is punched or rotated with the positioning blade of the mold, and the incision is stretched on both sides to form a mesh body with a fixed width, and the mesh body is cut to the required length. The plan is to cut three mesh bodies A2, the length L of which is the width L3 of the box bottom A3, the length L5 of the two structural slopes A5 at the corner between the box bottom A3 and the box body A4, and the height L4 of the two sides of the box body. And, namely: L=2L5 ten L3 ten 2L4; Mesh body A2 makes the U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com