Making method of graphene-based film with automatic cleaning function

A functional graphene, graphene-based technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problem that the self-cleaning function of graphene film has not been found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

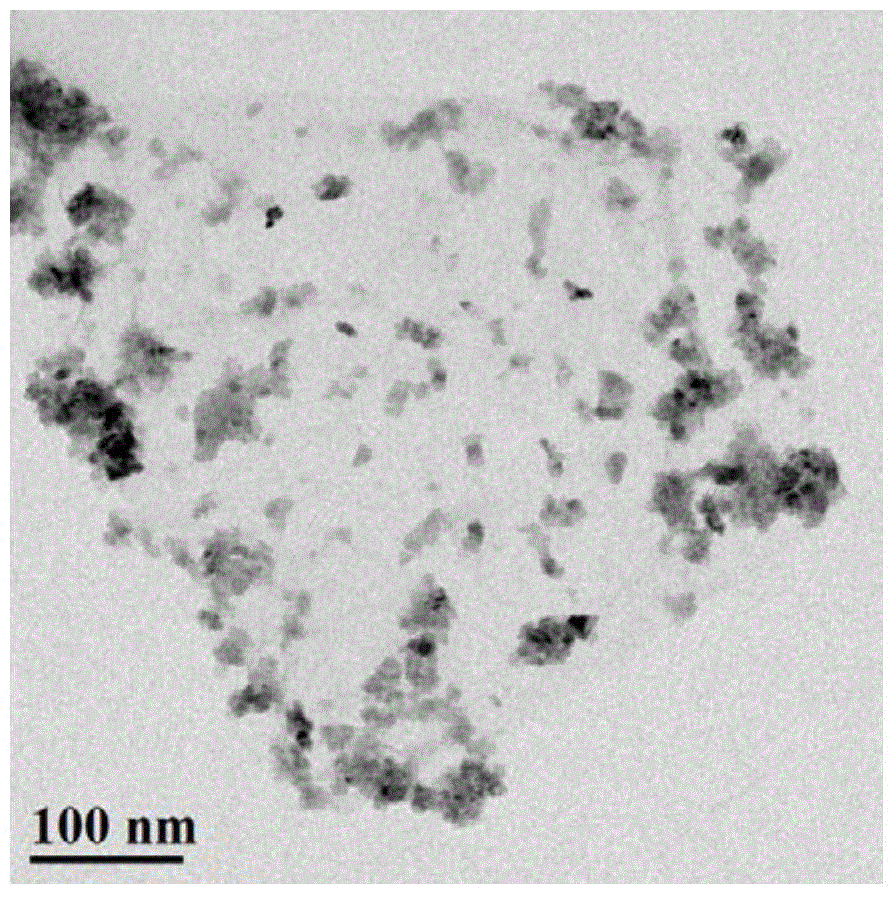

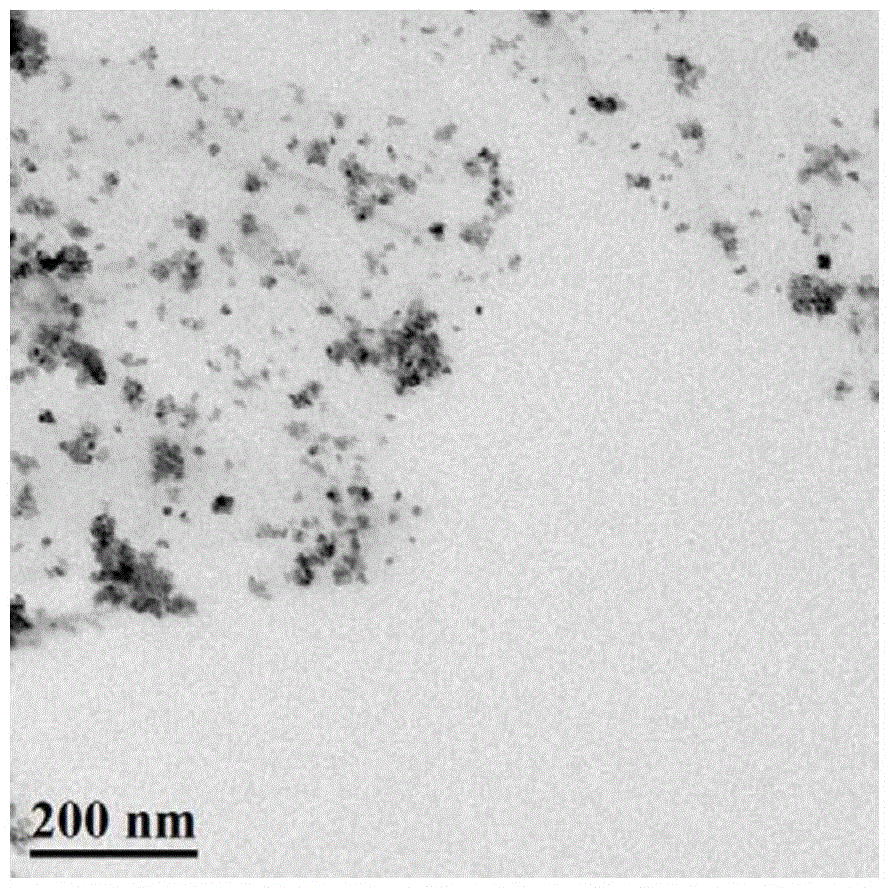

[0031] Use ethanol as the solvent to prepare 0.2mg / ml graphene oxide solution and 0.5mg / ml titanium dioxide solution. The two were blended so that the mass ratio of graphene oxide and titanium dioxide was 1:1, and the ultrasound was conducted for 30 minutes. The graphene oxide and titanium dioxide dispersion liquid is obtained. Take 6ml of the homogeneous solution and add it to the spray gun. The PC substrate is cleaned, then dried, and placed on a heating table to raise the temperature to 100°C. At this time, a spray gun connected with an air pump was used to spray the above solution on a PC substrate with an area of 5×5 cm, and the spray distance was about 5 cm. Prepared graphene oxide film / titanium dioxide film (such as figure 1 , figure 2 Shown). The film was placed in a 200ml methyl orange solution with a concentration of 2mg / L for degradation experiments. The power of the UV lamp is 175W, the distance between the lamp tube and the sample is 15cm, and the irradiatio...

Embodiment 2

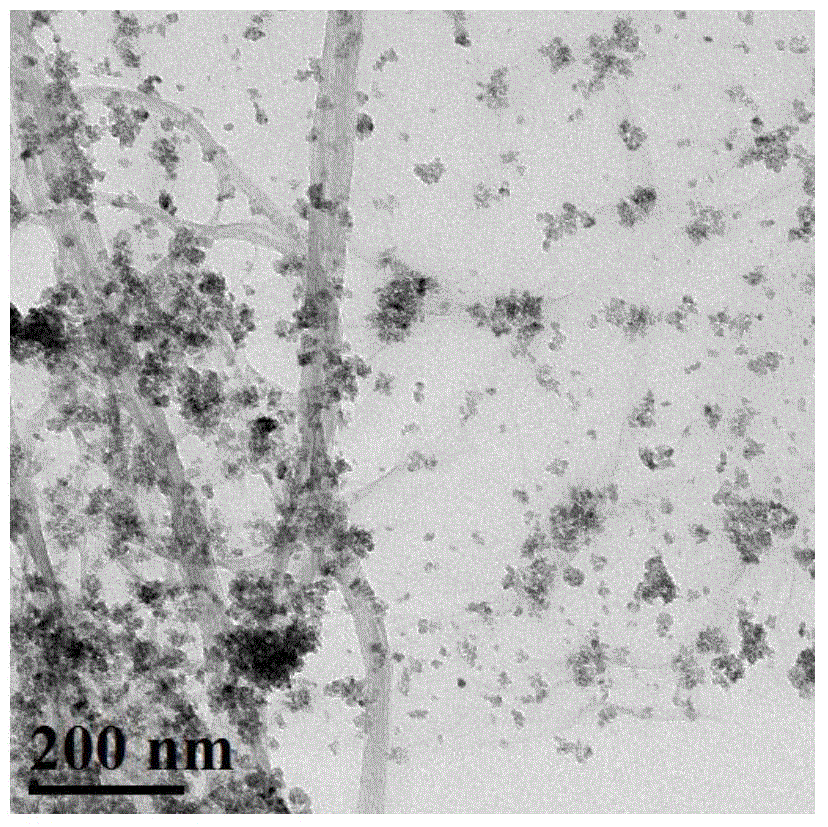

[0033] Using ethanol as a solvent, a 0.2 mg / ml graphene oxide solution was prepared, and carbon nanotubes were added to make the mass ratio of graphene oxide and carbon nanotubes 5:1. After 30 minutes of ultrasound, the graphene oxide / carbon nanotube composite solution was prepared. The 0.5mg / ml titanium dioxide solution was also prepared with ethanol solution as solvent. The three are blended so that the mass ratio of graphene oxide, carbon nanotubes and titanium dioxide is 5:1:5, and the ultrasound is performed for 10 minutes. The graphene oxide / carbon nanotube / titanium dioxide dispersion is obtained. Take 6ml of the homogeneous solution and add it to the spray gun. The PC substrate is cleaned, then dried, and placed on a heating table to raise the temperature to 100°C. At this time, a spray gun connected with an air pump was used to spray the above solution on a PC substrate with an area of 5×5 cm, and the spray distance was about 5 cm. The graphene oxide / carbon nanotu...

Embodiment 3

[0035] The preparation method of graphene-based film with self-cleaning function includes the following steps:

[0036] (1) Prepare graphene oxide dispersion in water / ethanol or ethanol solution. The concentration of graphene oxide is 0.1 mg / ml. After ultrasonic vibration, a graphene oxide dispersion with better dispersion and stability is prepared.

[0037] As a preferred mode, the graphene oxide dispersion is added with an enhanced conductive material, and the weight ratio of the graphene oxide to the enhanced conductive material is 1:1. The reinforced conductive material is carbon nanotubes or metal nanowires.

[0038] (2) The nano-sized titanium dioxide was added to the ethanol solution, and a titanium dioxide dispersion with a concentration of 0.1 mg / ml was prepared after ultrasonic for 1 hour.

[0039] (3) After blending the graphene oxide dispersion with the titanium dioxide dispersion, properly sonicate to obtain the graphene oxide / titanium dioxide dispersion. In the graphene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com