Cellulose based beer stabilizer and preparation method thereof

A technology of beer-based beer and stabilizer is applied in the field of cellulose-based beer stabilizer to achieve the effects of simple addition method, avoiding time-consuming and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A cellulose-based beer stabilizer, made of the following parts by weight: 10 parts of microcrystalline cellulose, 4 parts of sodium carboxymethylcellulose with a molecular weight of 6000, 4 parts of citric acid, 4 parts of sodium bicarbonate and 0.5 parts of polyethylene glycol with a molecular weight of 6000.

[0036] The preparation process of cellulose-based beer stabilizer:

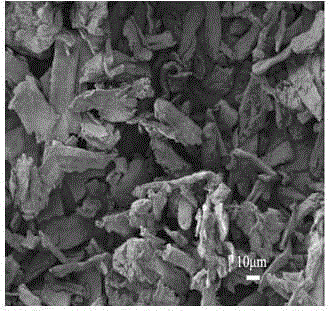

[0037] (1) Accurately weigh 10 g of microcrystalline cellulose, add 150 mL of 0.1 mol / L NaOH and mix well, boil for 15 min, wash thoroughly with water, filter, and dry for later use.

[0038] (2) Fully dissolve 4g sodium carboxymethyl cellulose in 150mL water, divide it into 2 equal parts, mix with 4g citric acid and 4g sodium bicarbonate respectively, stir and knead for 10 minutes, wrap citric acid and sodium bicarbonate respectively Buried in sodium carboxymethyl cellulose, then dried by blasting at 60°C, crushed and granulated. Under anhydrous conditions, the embedded citric acid and sodiu...

Embodiment 2

[0044] A cellulose-based beer stabilizer, made of the following parts by weight: 10 parts of microcrystalline cellulose, 4 parts of sodium carboxymethylcellulose with a molecular weight of 6000, 4 parts of citric acid, 4 parts of sodium bicarbonate and 1 part of polyethylene glycol with a molecular weight of 6000.

[0045] The preparation process of cellulose-based beer stabilizer:

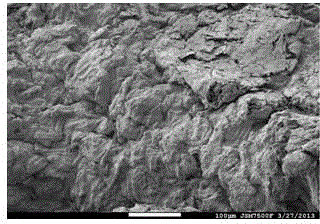

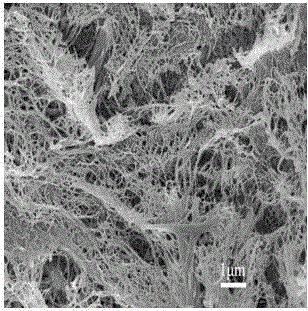

[0046] (1) Accurately weigh 10g of microcrystalline cellulose, add 150mL of 0.1 mol / L NaOH and mix evenly, keep it for 15min after boiling, wash thoroughly with water and suspend in water to prepare a 1.5% alkali-treated microcrystalline cellulose suspension . Using an APV2000 high-pressure homogenizer, the suspension was homogenized 20 times under a pressure of 1250 bar to obtain a white milky high-pressure homogenized microcrystalline cellulose (ie, microfibrillated cellulose) suspension. Filter and dry for later use.

[0047] (2) Fully dissolve 4g sodium carboxymethyl cellulose in 150mL wate...

Embodiment 3

[0053] A cellulose-based beer stabilizer, made of the following parts by weight: 3 parts of microcrystalline cellulose, 12 parts of sodium carboxymethylcellulose with a molecular weight of 5000, 3 parts of citric acid, 5 parts of sodium bicarbonate and 1 part of polyethylene glycol with a molecular weight of 4000.

[0054] The preparation process of cellulose-based beer stabilizer:

[0055] (1) Accurately weigh 3 g of microcrystalline cellulose, mix evenly with 100 mL of 0.1 mol / L NaOH, boil for 10 min, wash thoroughly with water and suspend in water to prepare a 1.5% alkali-treated microcrystalline cellulose suspension. Using an APV2000 high-pressure homogenizer, the suspension was homogenized 10 times under a pressure of 1250 bar to obtain a white milky microfibrillated cellulose suspension. Filter and dry for later use.

[0056] (2) Fully dissolve 12g sodium carboxymethylcellulose in 250mL water, divide it into 2 equal parts, mix them with 3g of citric acid and 5g of sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com