UV (ultraviolet) color paste capable of being used for optical fiber coloring printing ink and preparation method thereof

A technology of coloring ink and color paste, which is applied in the field of UV color paste of optical fiber coloring ink and its preparation, which can solve the problems of inability to directly purchase UV color paste, distinction, low lightness, etc., and achieve small fineness and good storage stability , The effect of fast grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

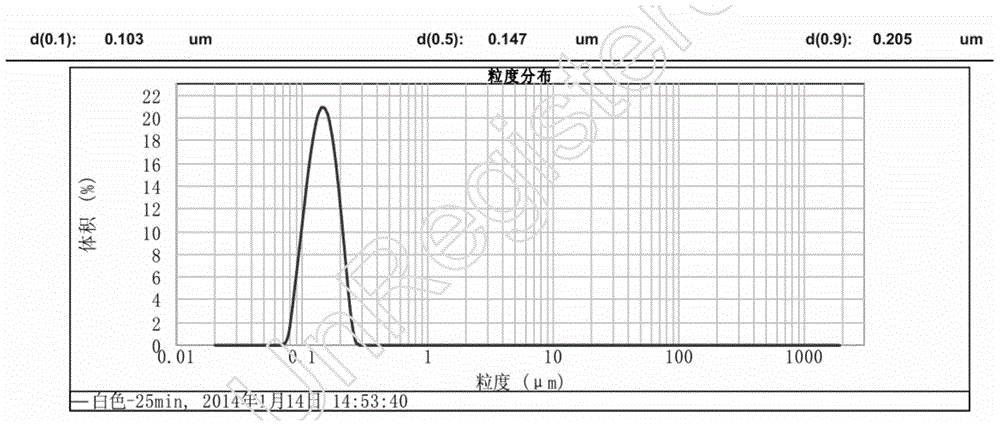

[0038] A UV white color paste that can be used for optical fiber coloring ink, the content of each component is as follows: 50% titanium dioxide white, 3% BYK-111, 1% BYK-1790, 10% self-made resin M-512 , 36% trimethylolpropane triacrylate, the sum of each component meets 100%, the specific preparation method is as follows: (1) trimethylolpropane triacrylate, self-made resin M-512, BYK-111 and BYK -1790 uniform mixing to obtain a mixed liquid component; then, under the stirring state of 500r / min, add the pigment titanium dioxide white to the mixed liquid component, after the pigment is added, increase the speed to 1000r / min and stir for 1.0 hour, The obtained UV crude color paste; (2) grind the UV crude color paste and use a laser particle size analyzer to measure the fineness, when all pigment particles are measured to be less than 1 micron, the UV color paste that can be used for optical fiber coloring ink is obtained. White color paste.

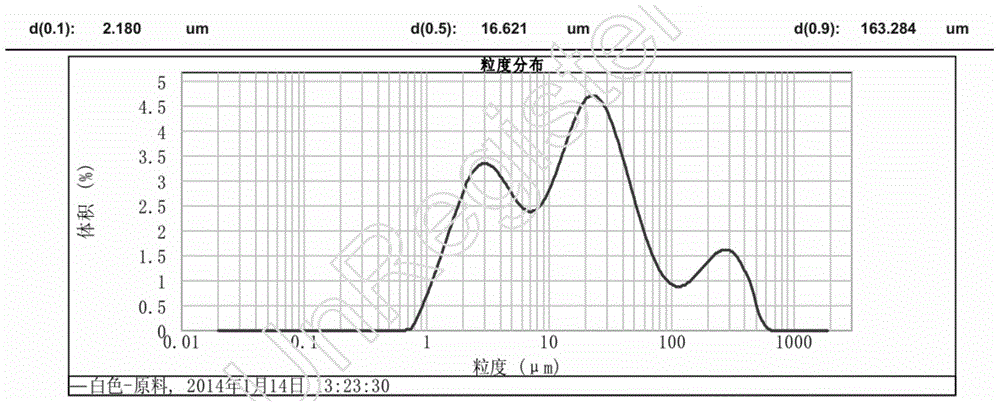

[0039] The initial fineness D90163...

Embodiment 2

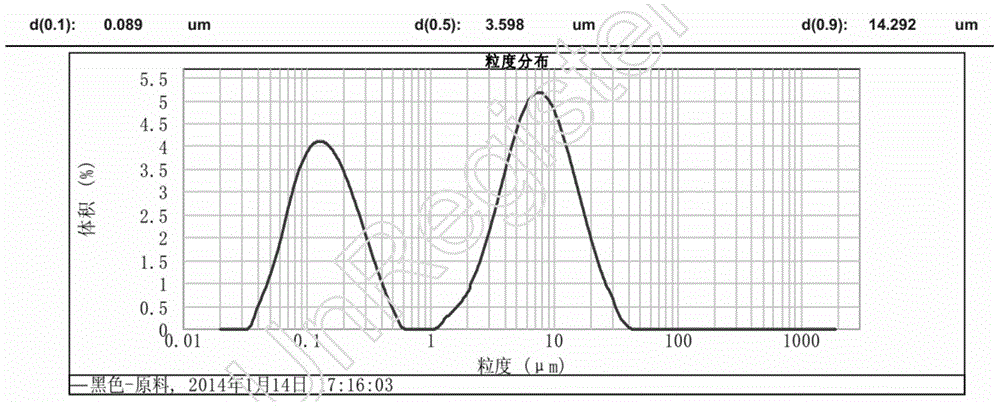

[0041] A UV black color paste that can be used for optical fiber coloring ink, the content of each component is: 20% carbon black, 18% BYK-163, 1% BYK-1790, 20% resin M-512, 41% trimethylolpropane triacrylate, the sum of each component meets 100%, is prepared according to the preparation method of Example 1, initial fineness D9014.292 micron (as image 3 shown), the final fineness D900.131 microns after grinding for 15 minutes (as Figure 4 shown).

Embodiment 3

[0043] A UV red color paste that can be used for optical fiber coloring ink, the content of each component is as follows: 20% quinacridone red, 8% BYK-163, 1% BYK-1790, 10% resin M -512, 61% tripropylene glycol diacrylate, the sum of each component meets 100%, is prepared according to the compounding method of embodiment 1, initial fineness D9086.654 micron (as Figure 5 shown), the final fineness D900.215 microns after grinding for 10 minutes (as Figure 6 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com