Wear-free thick laminated plate stirring friction brazing method adopting wide-shoulder tool with thick needle

A technology of friction stir and brazing method, applied in manufacturing tools, welding equipment, welding equipment and other directions, can solve the problems of poor oxide film removal effect, insufficient mechanical effect effect, insufficient thermal-mechanical effect effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] 1. Base metal and welding method

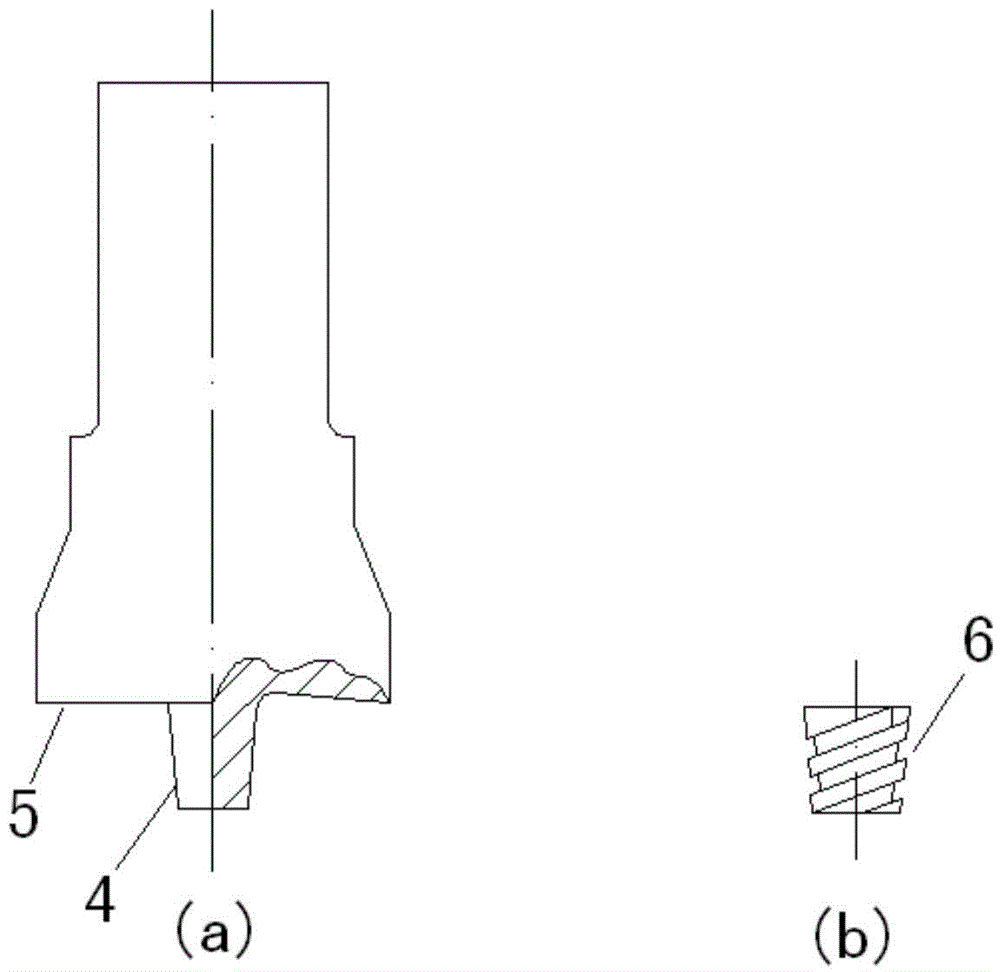

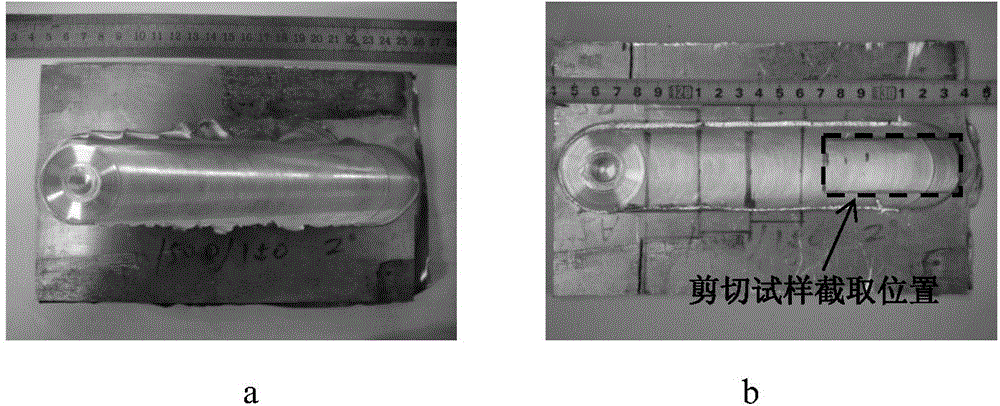

[0040] see figure 1 , The welding base material is pure aluminum plate (upper plate) with a thickness of 14mm and 304 stainless steel plate (lower plate) with a thickness of 2mm, and the solder is pure zinc foil with a thickness of 0.1mm. Before welding, polish the surface of the pure aluminum plate, stainless steel plate to be welded and both sides of the zinc foil with No. 240 sandpaper to remove the surface oxide film, and then wipe it with absolute ethanol. Pre-place the zinc foil between the two plates and perform welding. When welding, the needle tool is pressed into the pure aluminum plate, and the pressing depth is controlled at a distance of about 1mm between the stirring needle and the lower stainless steel base material, without contact with the stainless steel plate, and the inclination angle of the stirring head is 2o. After the stirring head is completely pressed into the aluminum base metal, it is preheated for about 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com