A vacuum welding device and its installation and use method

A vacuum welding and pedestal technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of shape and position tolerance, unable to complete multiple key parts of the main body at the same time, to improve the yield, smooth the path, avoid uncontrollable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

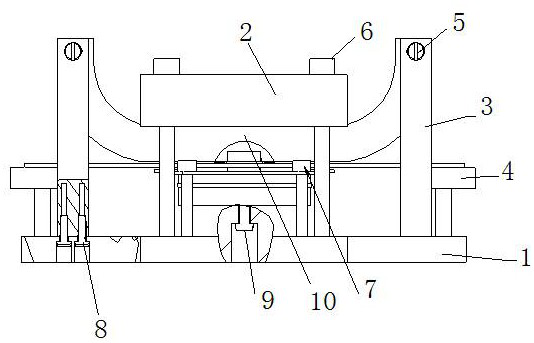

[0044] A vacuum welding device, see figure 1 , including a bottom base 1, a transverse top plate 2, a longitudinal side wall adjustment column 3, a longitudinal magnetic shield adjustment screw 4 and a transverse adjustment screw 5;

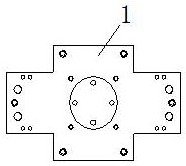

[0045] please see figure 2 and image 3 , the left side and the right side of the bottom base 1 are respectively connected with side wall adjustment columns 3, the bottom base 1 is provided with a table for placing the main body 10 of the U-shaped structure, and the table is located between the side wall adjustment columns 3 The arc-shaped convex surface between;

[0046] please see Figure 4 , Figure 5 , the bottom base 1 is provided with a top platen 2 for clamping and fixing the main body 10 with the table top, and the first platen for fixing the top platen 2, the main body 10 and the bottom base 1 passes between the top platen 2 and the bottom base 1 The fixing part 6 is connected and fixed;

[0047] please see Figure 6 and Figure...

Embodiment 2

[0059] A vacuum welding device, similar to Embodiment 1, the difference is that at least four first fixing holes evenly distributed in a square are arranged on the main body 10, the top platen 2 and the bottom base 1 respectively, the main body 10, The top pressing plate 2 and the bottom base 1 are connected and fixed through the first fixing member 6 arranged in the first fixing hole.

[0060] It may further be provided that at least four second fixing holes evenly distributed into a square are arranged on the table and the main body 10, the second fixing holes are screw holes, and the outer wall of the second fixing member 7 is provided with The external thread matched with the second fixing hole, the main body 10 and the bottom base 1 are connected through the second fixing member 7 arranged in the second fixing hole.

[0061] It can be further improved that column holes are respectively provided on the left and right sides of the upper surface of the bottom base 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com