Fusion welding device used for optical polycarbonate transparent cover and application method of fusion welding device

A polycarbonate and transparent cover technology, which is applied in the field of welding equipment, can solve the problems of poor product appearance and uneven force, and achieve the effect of ensuring fit, uniform force, and guaranteed force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

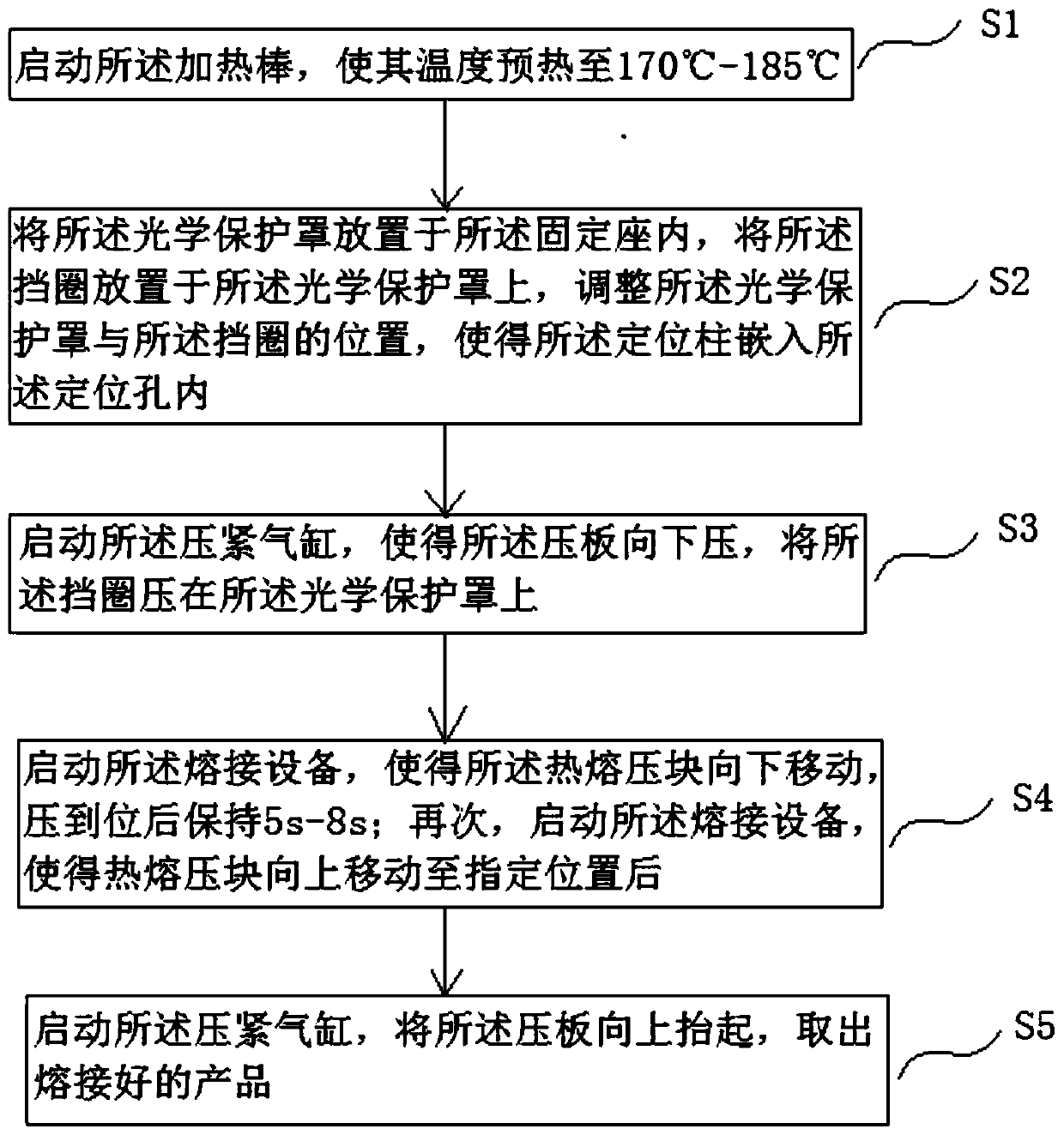

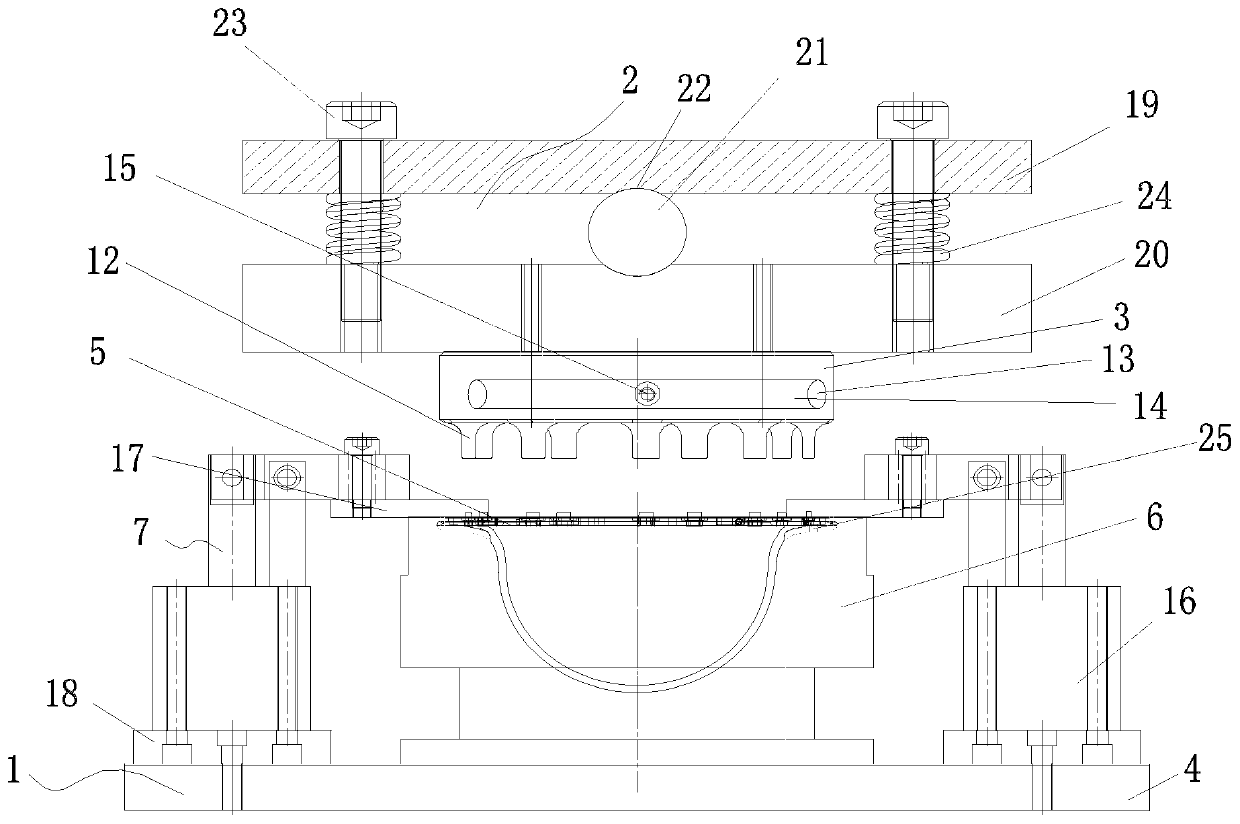

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

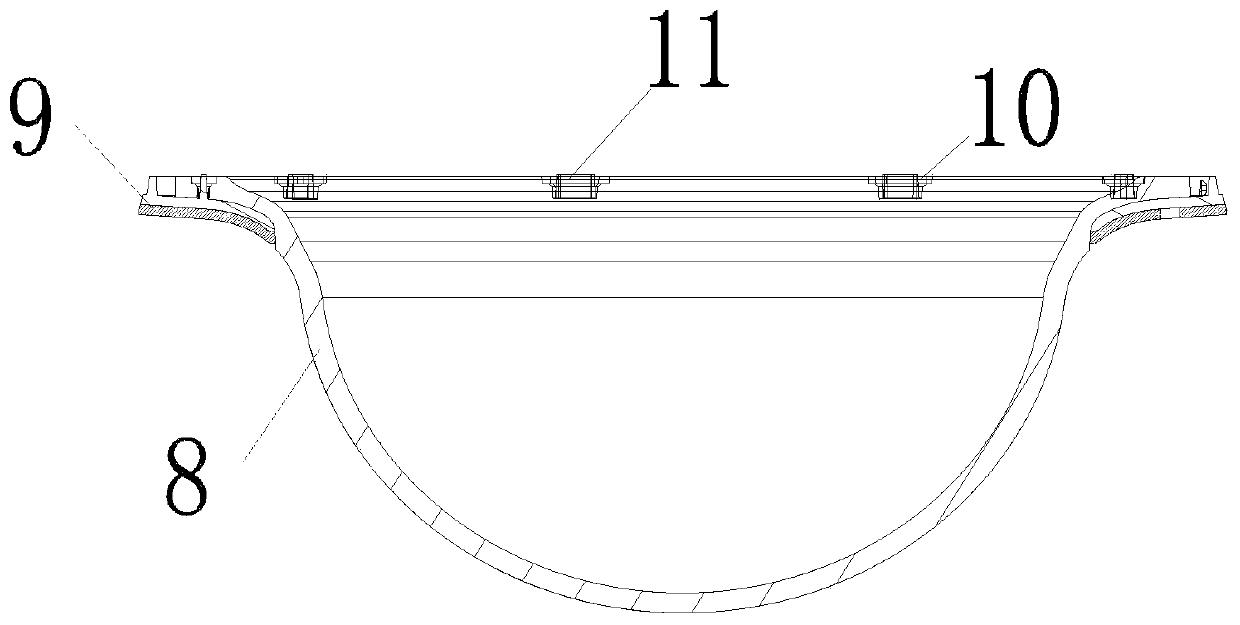

[0021] Please refer to Figure 2 to Figure 5 , in one embodiment of the present invention, a welding device for optical-grade polycarbonate transparent cover, including welding equipment (not shown), also includes a fixing assembly 1, an adjustment mechanism 2 and a hot-melt pressing block 3; The fixing assembly 1 includes a bottom plate 4, the middle part of the bottom plate 4 is provided with a fixing seat 6 for fixing the product 5 to be welded, the product 5 is placed on the fixing seat 6, and the fixing seat 6 gives The product 5 provides a supporting force, and the product 5 is limited, and the left and right sides of the bottom plate 4 are provided with a pressing mechanism 7 for clamping the product 5. Using the pressing mechanism 7 The product 5 is pre-pressed to meet the requirement that the product 5 has a good fit before welding; the product 5 includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com