Machining tool and machining method for controlling coaxiality and parallelism of parts

A process of processing knives and processing methods, which is used in the field of mechanical parts machine processing, can solve problems such as difficulty control of coaxial axis, reducing the efficiency of parts processing, and affecting the qualification rate of the parts. . The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

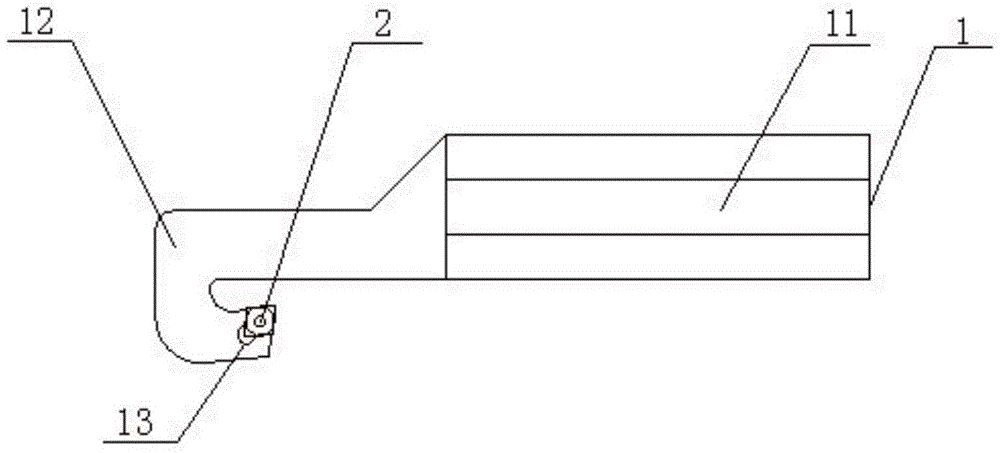

[0026] Such as figure 1 The shown processing tool for controlling the coaxiality and parallelism of parts includes a turning tool holder 1 and a processing blade 2. The turning tool holder 1 is in the shape of an "L" placed horizontally and includes a turning tool holder clamping part 11 And the turning tool bar processing part 12, the turning tool bar processing part 12 on the turning tool bar 1 is bent counterclockwise downwards into a "U" shape structure, wherein the turning tool bar processing part 12 is bent to be roughly in line with the turning tool bar The parts of the clamping parts 11 that are parallel to each other form a blade mounting part 13, and the end of the blade mounting part 13 is fixedly connected with the processing blade 2, and the processing blade 2 and the clamping part 11 of the turning tool holder are parallel to each other. The diameter of the turning tool bar clamping portion 11 on the turning tool bar 1 is greater than the diameter of the turning ...

Embodiment 2

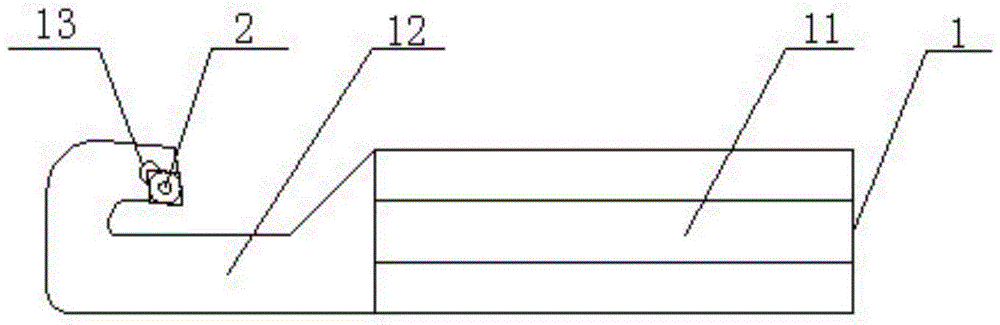

[0028] Such as figure 2 In the shown processing tool for controlling the coaxiality and parallelism of parts, the turning tool bar processing part 12 on the turning tool bar 1 is bent upwards clockwise into a "U"-shaped structure, and other structures are the same as in Embodiment 1.

Embodiment 3

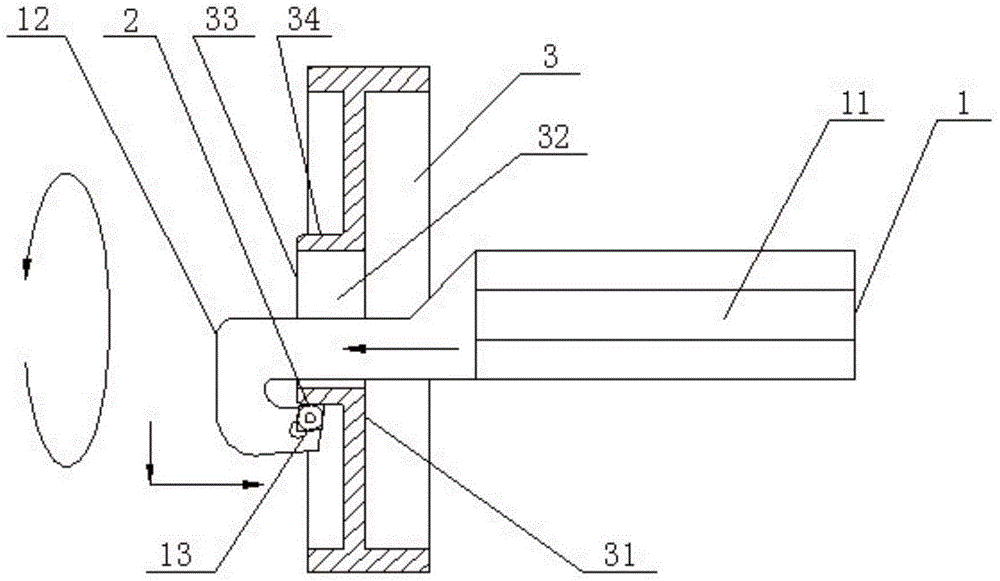

[0030] Such as Figure 4 The shown processing tool for controlling the coaxiality and parallelism of parts includes a turning tool bar 1 and a machining blade 2. The turning tool bar 1 is in the shape of an "L" placed horizontally. The tool bar processing part 12 is bent counterclockwise downwards into a right-angled structure, and the end of the turning tool bar processing part 12 is fixedly connected with the processing blade 2, and the processing blade 2 and the turning tool bar clamping part 11 are parallel to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com