Au-Pd/graphene catalyst and preparation method and application thereof

A graphene and catalyst technology, applied in the field of catalyst preparation and sustainable development of the environment and energy, to achieve the effects of environmental friendliness, high photocatalytic activity and selectivity, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

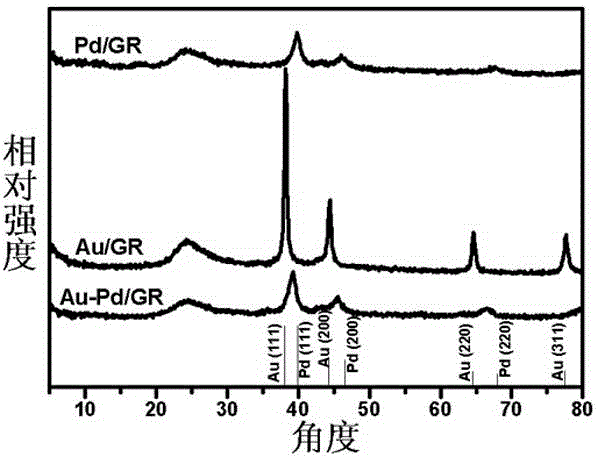

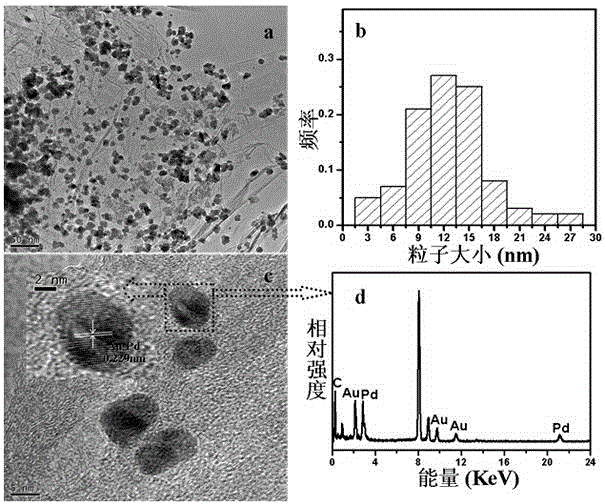

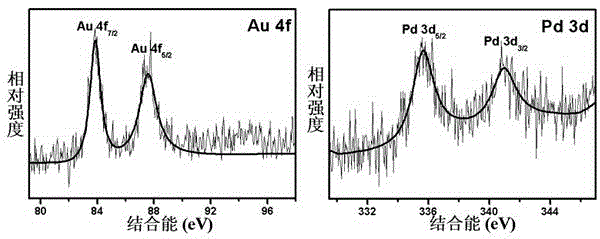

Embodiment 1

[0034] 95 mg of graphene oxide was ultrasonically dispersed in 100 mL of deionized water, followed by the addition of 1.27 mL of 10 mM HAuCl 4 and 2.35 mL of 10 mM H 2 PdCl 4 solution and stirred for 0.5 h. While stirring, slowly add 50 mL of 0.15 M NaBH 4 solution, and then the reaction solution was heated to reflux at 100 °C for 24 h. After the reaction was completed and cooled to room temperature, the solid-liquid was separated by filtration, the solid was washed with water, and dried in an oven at 60°C to obtain a 2.5 wt %Au-2.5 wt %Pd / GR catalyst. For comparison, only a single metal precursor salt was added to synthesize 5 wt %Au / GR and 5 wt %Pd / GR catalysts under the same conditions. In a 100 mL thermal catalytic reactor, add 50 mg of catalyst and 20 mL of benzyl alcohol and stir to mix evenly, then set the thermal catalytic reaction conditions, the reaction temperature is 100 ° C, the stirring rate is 1500 rpm and the pressure is 3 atmospheres Oxygen, along with th...

Embodiment 2

[0038] 95 mg of graphene oxide was ultrasonically dispersed in 100 mL of deionized water, followed by the addition of 1.27 mL of 10 mM HAuCl 4 and 2.35 mL of 10 mM H 2 PdCl 4 solution and stirred for 0.5 h. While stirring, slowly add 50 mL of 0.15 M NaBH 4 solution, and then the reaction solution was heated to reflux at 100 °C for 24 h. After the reaction was completed and cooled to room temperature, the solid-liquid was separated by filtration, the solid was washed with water, and dried in an oven at 60°C to obtain a 2.5 wt %Au-2.5 wt %Pd / GR catalyst. For comparison, only a single metal precursor salt was added to synthesize 5 wt %Au / GR and 5 wt %Pd / GR catalysts under the same conditions. 80 mg of NaBH 4 Mix well with 160 mL of p-nitroaniline with a concentration of 10 ppm, and then add 5 mg of catalyst. With the progress of the catalytic reaction, p-nitroaniline is reduced to p-phenylenediamine. The relevant data are shown in Table 2.

[0039] Table 2 is the activity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com