Child type special cereal cooking-free noodles and production method thereof

A kid-friendly noodle-cooking technology, applied in application, food preparation, food science, etc., can solve the problems of high fat content in instant noodles, low dietary fiber content, human malnutrition, etc., to promote children's brain cell development, reasonable diet, Promotes the conduction of nerve media and the effect of retinal formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

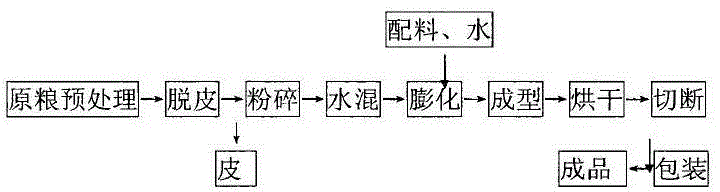

Image

Examples

Embodiment 1

[0023] A special non-cooking noodles for children, the specific preparation steps are as follows:

[0024] (1) Raw material pretreatment: remove miscellaneous grain raw materials and remove bad particles;

[0025] (2) Peeling: Raw materials such as sorghum and buckwheat need to be peeled;

[0026] (3) Grinding: The raw materials are divided into 13% corn, 7% soybean, 4% barley, 30% millet, 10% red bean, 10% oat, 5% buckwheat, 6% mung bean, 7% sorghum, 3% yellow rice, The ratio of gluten powder 5% is mixed and put into pulverizer to pulverize, cross 200 mesh sieves;

[0027] (4) Water mixing: add 2% salt, 1% compound phosphate, and 0.5% edible alkali to the mixed raw materials, and then mix with water to adjust the moisture content to about 16%;

[0028] (5) Extrusion and puffing: extrude the mixed raw materials through a twin-screw extrusion puffing machine, the puffing temperature is 160-165°C, and the screw speed is 100-120r / min;

[0029] (6) Forming: After puffing, form ...

Embodiment 2

[0034] A special non-cooking noodles for children, the specific preparation steps are as follows:

[0035] (1) Raw material pretreatment: remove miscellaneous grain raw materials and remove bad particles;

[0036] (2) Peeling: Raw materials such as sorghum and buckwheat need to be peeled;

[0037] (3) Crushing: The raw materials are divided into 18% corn, 5% soybean, 6% barley, 20% millet, 14% red bean, 8% oat, 7% buckwheat, 4% mung bean, 9% sorghum, 3% yellow rice, The ratio of gluten powder 6% is mixed and put into pulverizer to pulverize, cross 200 mesh sieves;

[0038] (4) Water mixing: Add 4% salt, 1% compound phosphate and 0.3% edible alkali to the mixed raw materials, and then mix with water to adjust the moisture content to about 16%;

[0039] (5) Extrusion and puffing: extrude the mixed raw materials through a twin-screw extrusion puffing machine, the puffing temperature is 160-165°C, and the screw speed is 100-120r / min;

[0040] (6) Forming: After puffing, form fo...

Embodiment 3

[0045] A special non-cooking noodles for children, the specific preparation steps are as follows:

[0046] (1) Raw material pretreatment: remove miscellaneous grain raw materials and remove bad particles;

[0047] (2) Peeling: Raw materials such as sorghum and buckwheat need to be peeled;

[0048](3) Crushing: The raw materials are divided into 15% corn, 6% soybean, 5% barley, 25% millet, 12% red bean, 9% oat, 6% buckwheat, 5% mung bean, 8% sorghum, 4% yellow rice, The ratio of gluten powder 5% is mixed and put into pulverizer to pulverize, cross 200 mesh sieves;

[0049] (4) Water mixing: add 3% salt, 1.5% compound phosphate, and 0.4% edible alkali to the mixed raw materials, and then mix with water to adjust the moisture content to about 16%;

[0050] (5) Extrusion and puffing: extrude the mixed raw materials through a twin-screw extrusion puffing machine, the puffing temperature is 160-165°C, and the screw speed is 100-120r / min;

[0051] (6) Forming: After puffing, form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com