Fan coil cold measuring method based on flow-cold relation model

A technology of fan coil unit and metering method, which is applied in the direction of calculation, special data processing applications, instruments, etc., and can solve the problem of low failure rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

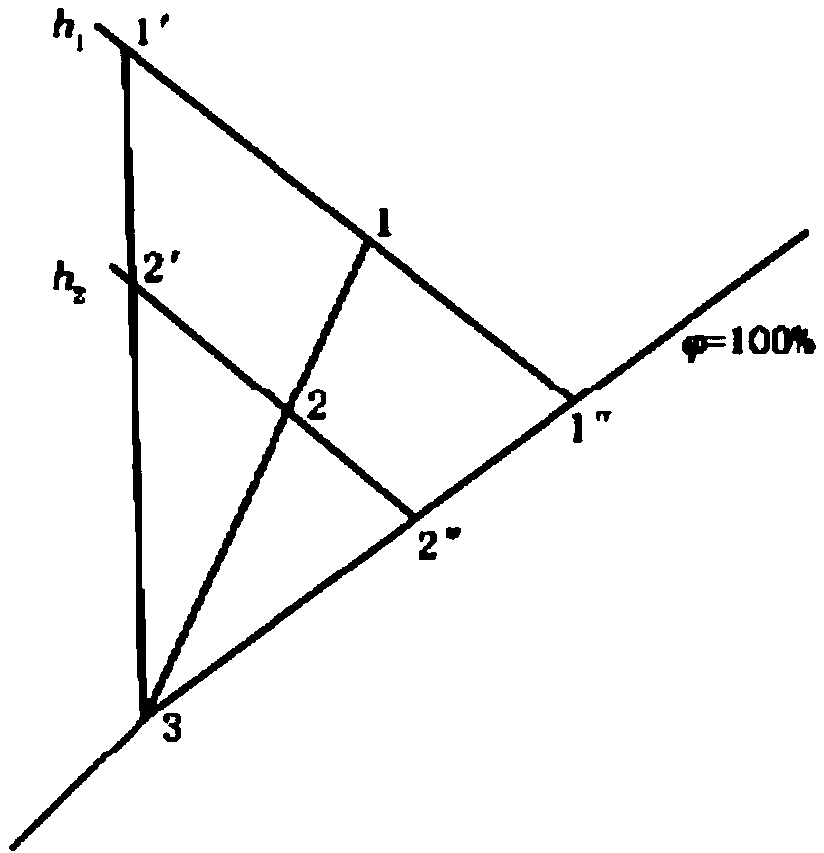

Method used

Image

Examples

Embodiment 1

[0253] This embodiment is mainly to illustrate the applicability of the present invention under different wind speed gear conditions:

[0254] (1) The model of the fan coil unit is FP-51; the structural parameters of the fan coil unit are: the tube row is 8×3 flat-sleeved tube type, the copper tube is 10×1mm, the length is 528mm, arranged in a regular triangle, the thickness of the aluminum fins and The spacing is 0.115mm and 2.35mm respectively, the vertical airflow direction tube spacing is 25mm, the ribbing coefficient is 14.5, and the windward area is 0.052m 2 , with a total heat transfer area of 6.76m 2 ;

[0255] (2) The air volumes of the high, medium and low levels are 510m respectively 3 / h, 390m 3 / h, 260m 3 / h;

[0256] (3) The water supply temperature is 13°C;

[0257] (4) The indoor air temperature is controlled at (28°C / 55%RH);

[0258] As mentioned above, due to the change of the water supply flow rate, the cooling capacity of the fan coil unit changes....

Embodiment 2

[0261] This embodiment is mainly to illustrate the applicability of the present invention under different indoor air setting states (temperature and humidity):

[0262] (1) The model of the fan coil unit is FP-51; the structural parameters of the fan coil unit are: the tube row is 8×3 flat-sleeved tube type, the copper tube is 10×1mm, the length is 528mm, arranged in a regular triangle, the thickness of the aluminum fins and The spacing is 0.115mm and 2.35mm respectively, the vertical airflow direction tube spacing is 25mm, the ribbing coefficient is 14.5, and the windward area is 0.052m 2 , with a total heat transfer area of 6.76m 2 , air volume 510m 3 / h;

[0263] (2) The water supply temperature is 13°C;

[0264] (3) The indoor air temperature is controlled at (28°C / 55%RH) and (26°C / 45%RH);

[0265] Under the above-mentioned different indoor air setting conditions (temperature and humidity), the cooling capacity of the fan coil unit changes with the flow rate as follo...

Embodiment 3

[0268] This embodiment is mainly to illustrate the applicability of the present invention under different water supply temperature setting conditions:

[0269] (1) The model of the fan coil unit is FP-51; the structural parameters of the fan coil unit are: the tube row is 8×3 flat-sleeved tube type, the copper tube is 10×1mm, the length is 528mm, arranged in a regular triangle, the thickness of the aluminum fins and The spacing is 0.115mm and 2.35mm respectively, the vertical airflow direction tube spacing is 25mm, the ribbing coefficient is 14.5, and the windward area is 0.052m 2 , with a total heat transfer area of 6.76m 2 , air volume 510m 3 / h;

[0270] (2) The indoor air temperature is controlled at (28°C / 55%RH);

[0271] (3) The water supply temperature is set to 7°C, 10°C, and 13°C respectively;

[0272] Under the above-mentioned different indoor air setting conditions (temperature and humidity), the cooling capacity of the fan coil unit changes with the flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com