A kind of preparation method of hemp fiber mattress material

A technology of hemp fiber and jute fiber, which is applied in the field of preparation of hemp fiber mattress materials, can solve the problems of comfort and environmental protection, antibacterial and breathable service life to be improved, and achieve the effects of comfortable mood, good ventilation and promoting blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Select jute fiber for use; The preparation method of jute fiber mattress material comprises the following steps:

[0053] (1) Opening: First, the jute fibers are degummed, then combed and shortened into short jute fibers, and then the short jute fibers are sent to the opening machine for opening;

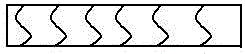

[0054] (2) Combing into a web by airflow: the short jute fibers after opening are uniformly flowed down from the drum groove through the airflow, and the short jute fibers after opening are evenly arranged by the airflow to form as shown in Fig. figure 1 A netted semi-finished product with an S-shaped cross-section structure;

[0055] (3) Non-woven needle punching: The net-like semi-finished product undergoes at least two spunlace treatments reinforced by water needles, and is compounded and entangled to form a non-woven needle-punched jute fiber semi-finished product;

[0056] (4) High-temperature baking: The non-woven needle-punched jute fiber semi-finished product is plac...

Embodiment 2

[0073] Select jute fiber for use, and the preparation method of jute fiber mattress material may further comprise the steps:

[0074] (1) Opening: First, the jute fibers are degummed, then combed and shortened into short jute fibers, and then the short jute fibers are sent to the opening machine for opening;

[0075] (2) Combing into a net by airflow: the short jute fibers after opening are evenly lowered from the drum groove through the airflow, and the short jute fibers after opening are evenly arranged by the airflow to form a mesh semi-finished product with an S-shaped cross-section structure;

[0076] (3) Non-woven needle punching: The net-like semi-finished product undergoes at least two spunlace treatments reinforced by water needles, and is compounded and entangled to form a non-woven needle-punched jute fiber semi-finished product;

[0077] (4) High-temperature baking: The non-woven needle-punched jute fiber semi-finished product is placed in a high temperature of 180...

Embodiment 3

[0094] Select jute fiber for use, and the preparation method of jute fiber mattress material may further comprise the steps:

[0095] (1) Opening: First, the jute fibers are degummed, then combed and shortened into short jute fibers, and then the short jute fibers are sent to the opening machine for opening;

[0096] (2) Combing into a net by airflow: the short jute fibers after opening are evenly lowered from the drum groove through the airflow, and the short jute fibers after opening are evenly arranged by the airflow to form a mesh semi-finished product with an S-shaped cross-section structure;

[0097] (3) Non-woven needle punching: The net-like semi-finished product undergoes at least two spunlace treatments reinforced by water needles, and is compounded and entangled to form a non-woven needle-punched jute fiber semi-finished product;

[0098] (4) High-temperature baking: The non-woven needle-punched jute fiber semi-finished product is placed in a high temperature of 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com