Improved process of weaving perforated sheet with hook and loop without combing

A technology of perforated sheet and hook and loop, which is applied in the direction of textiles, papermaking, textiles, looms, etc., can solve the problems of large processing wear of terry 22, messy and broken hair of terry 22, failure to meet customer requirements, etc., to achieve The effect of saving yarn consumption, improving structural strength and shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A non-combing improvement process for weaving perforated sheets using hook and loop fasteners, comprising the following steps:

[0032] ① Whole yarn: weave raw material yarns into embryo belts according to the warp yarn, weft yarn and wool yarn respectively, and put them into the loom according to the ratio of warp yarn, weft yarn and wool yarn length ratio of 2:1:1.1;

[0033] ②Basic weaving: Weave the base layer of the hook and loop according to the ratio of two strands of warp yarn and one strand of weft yarn;

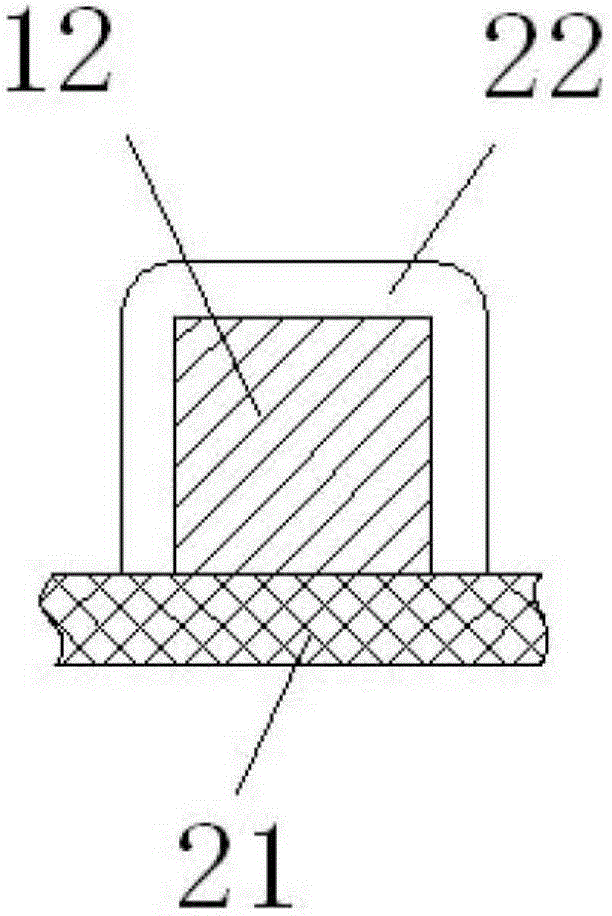

[0034] ③ Terry weaving: use the perforated sheet as a support, weave loops on the base layer with wool yarn;

[0035] ④Heat-shrinking treatment: Heat-shrinking the woven Velcro through boiling water.

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

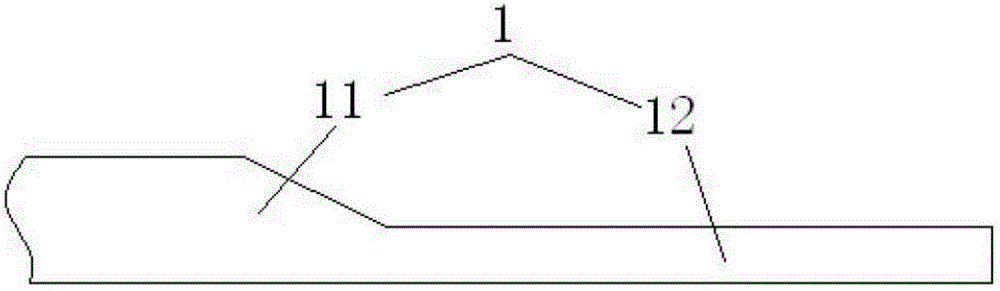

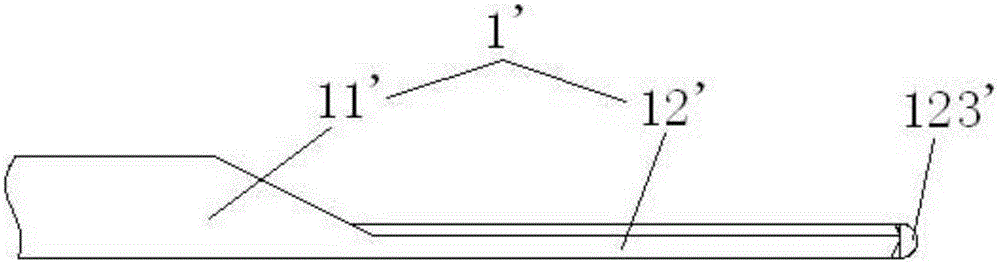

[0037] Such as image 3 , Figure 4 As shown, the present invention is a weaving perforated sheet 1' for Velcro, which is used for weavin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com