Environment-friendly water-based synthetic metal machining liquid

A metal cutting fluid, an environment-friendly technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve problems such as poor lubricity and anti-corrosion performance, achieve good cleaning effect, good lubricity, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

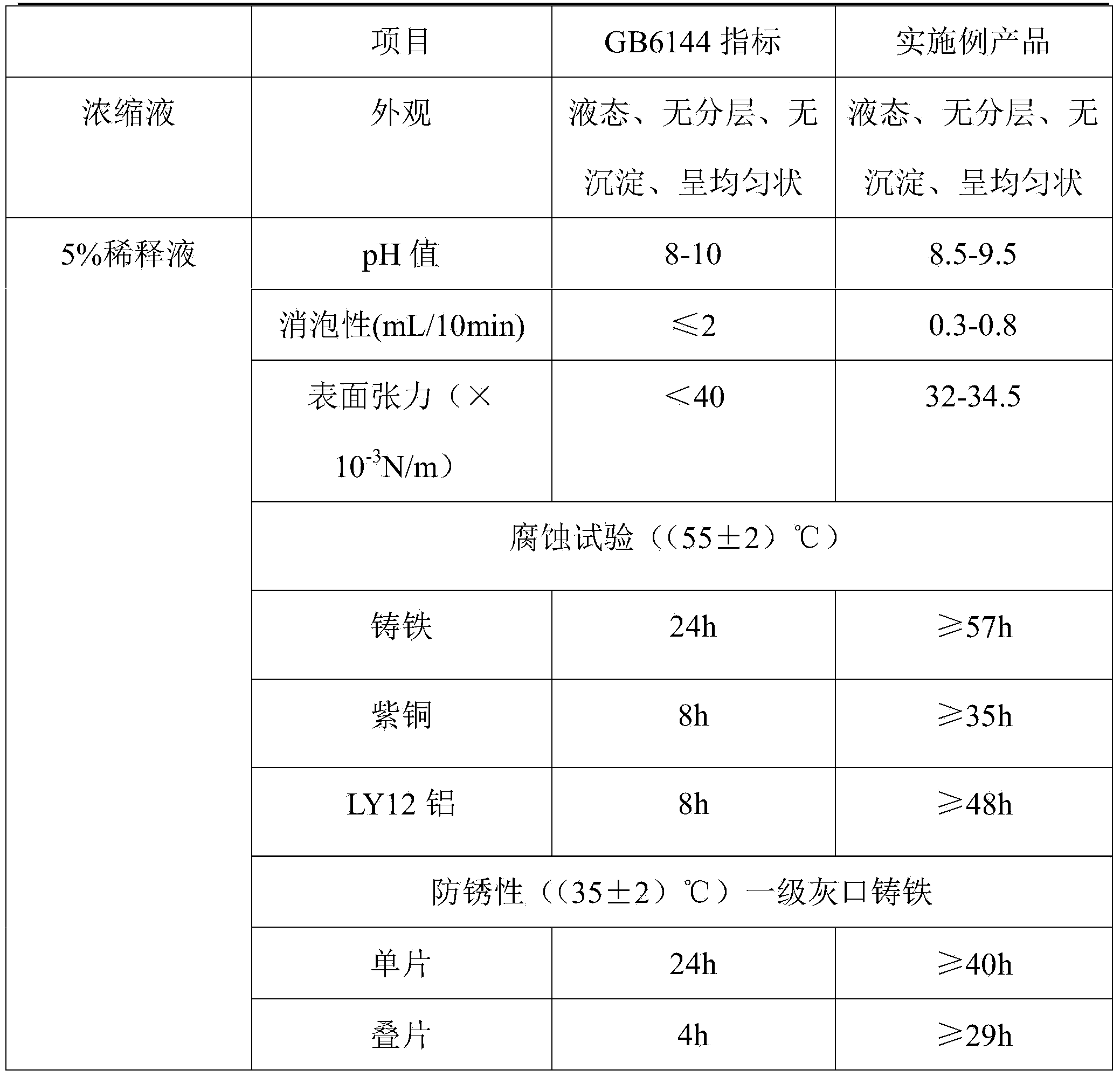

Examples

Embodiment 1

[0020] The environment-friendly water-based synthetic metal cutting fluid of the present invention, its raw materials include by weight: 10.8 parts of triethanolamine sebacate, 12 parts of benzotriazole, 7.6 parts of sodium benzoate, and 9 parts of dodecenylsuccinic acid , 12.3 parts of n-alcohol laurate, 6 parts of triethanolamine oleate, 12.5 parts of boric acid ester, 8.9 parts of polyether type nonionic surfactant, 5.8 parts of triethanolamine, 4.3 parts of ethylenediaminetetraacetic acid, 5.6 parts of borax, 3.6 parts of chelating agent, 2.6 parts of fungicide, 4 parts of defoamer, 160 parts of water.

Embodiment 2

[0022] The environment-friendly water-based synthetic metal cutting fluid of the present invention, its raw material comprises by weight: 10 parts of triethanolamine sebacate, 13 parts of benzotriazole, 5 parts of sodium benzoate, 10 parts of dodecenylsuccinic acid , 5 parts of n-alcohol laurate, 10 parts of triethanolamine oleate, 15 parts of triethanolamide borate laurate, 20 parts of polyether nonionic surfactant, 5 parts of triethanolamine, 3 parts of ethylenediaminetetraacetic acid , 10 parts of borax, 2 parts of chelating agent, 3 parts of fungicide, 2 parts of defoamer, 180 parts of water.

Embodiment 3

[0024] The environment-friendly water-based synthetic metal cutting fluid of the present invention, its raw materials include by weight: 25 parts of triethanolamine sebacate, 5 parts of benzotriazole, 10 parts of sodium benzoate, 3 parts of dodecenylsuccinic acid , 13 parts of n-alcohol laurate, 5 parts of triethanolamine oleate, 3 parts of O-(N-succinimide)-1,1,3,3-tetramethylurea tetrafluoroboric acid, triethanolamine borate 2 parts, 8 parts of polyether nonionic surfactant, 8 parts of triethanolamine, 5 parts of ethylenediaminetetraacetic acid, 5 parts of borax, 1 part of bishydroxyethylglycine, 2 parts of aspartic acid, 2 parts of aminepentaacetic acid, 0.5 parts of 2-methyl-4-isothiazolin-3-one, 4 parts of polyether defoamer, 1 part of simethicone, and 120 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com