Ultrapure argon online purification system and method

A purification system, pure argon technology, applied in the field of absorption and desorption of neutral impurity nitrogen, ultra-pure argon online purification system, can solve the problems of demanding purification container, unable to meet the process requirements, and not involving neutral impurity gas, etc. Achieve the effect of eliminating pollution and good air suction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

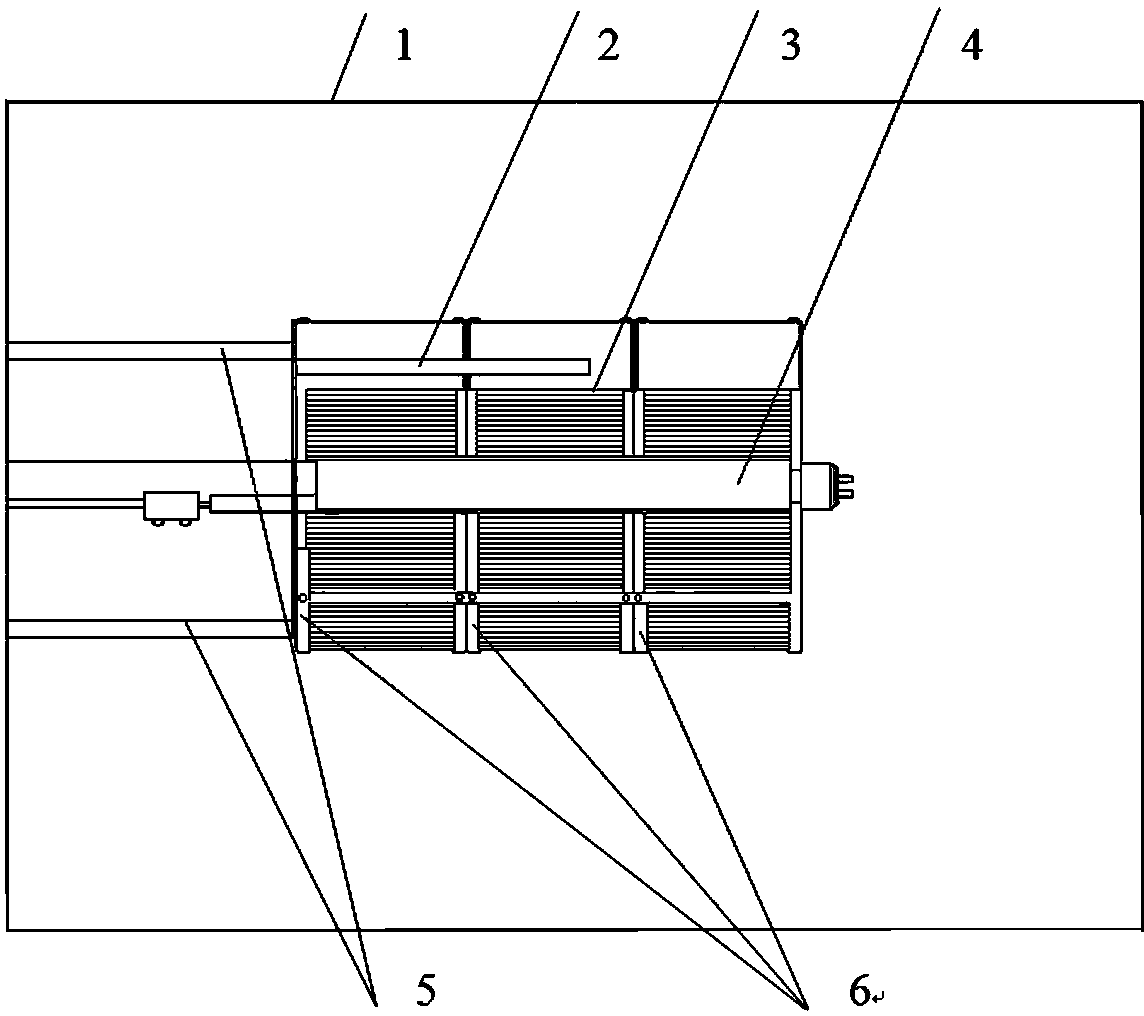

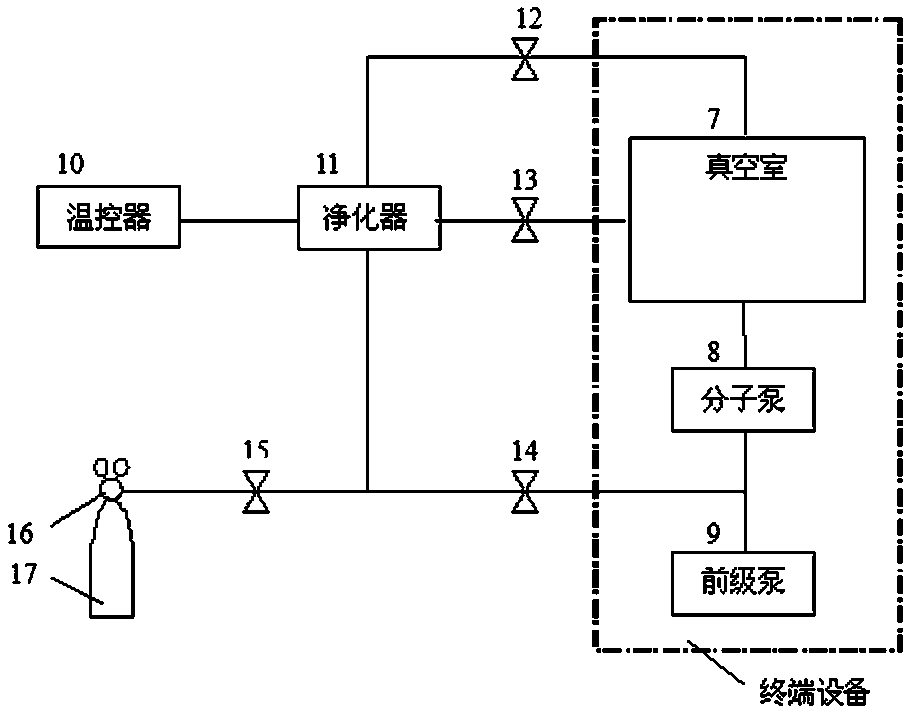

[0034] The ultra-pure argon on-line purification system used in mass spectrometry includes terminal equipment consisting of a process vacuum chamber 7, a backing pump 9, a molecular pump 8 and a vacuum gauge, and is characterized in that the high-purity argon in the high-pressure gas cylinder 17 is passed The decompression valve 16 is adjusted to the working air pressure, and after being purified by the input valve 15 to the purifier 11, it is adjusted to the working air pressure through the output regulating valve 12, and is delivered to the vacuum chamber 7 of the terminal equipment; the purifier 11 is connected to the terminal equipment through the isolation valve 13. The vacuum chamber 7 is connected to the molecular pump 8 and the backing pump 9 through the initial pumping valve 14. The purpose is to make full use of the vacuum system of the terminal equipment to clean, activate and degas the purifier 11 before working, so as Ensure the clean working environment of the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com