Silicon single crystal and method for manufacture thereof

A manufacturing method and technology of single crystal silicon, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of high temperature, high cost, poor crystallization yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

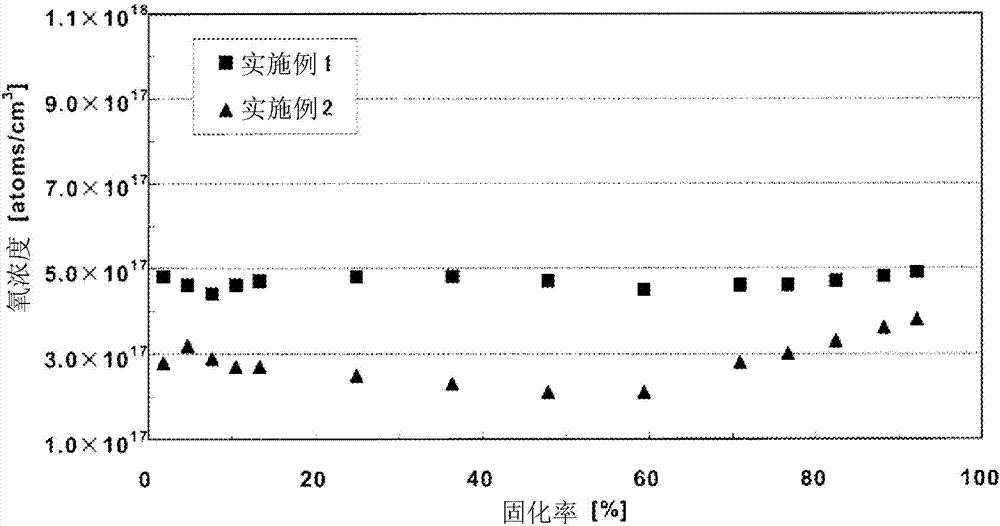

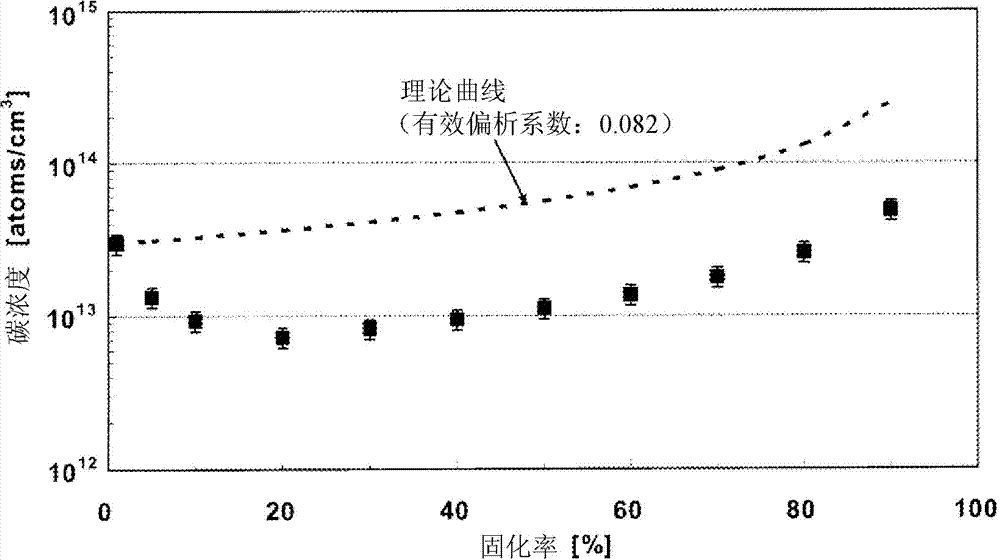

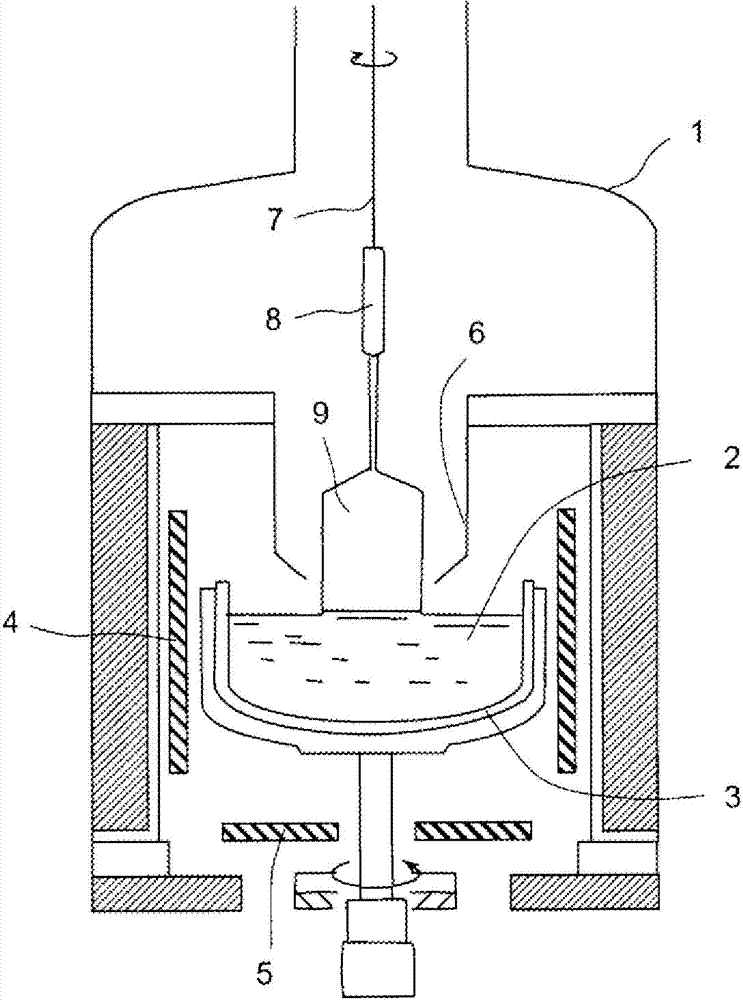

[0091] in figure 1 In the single crystal pulling device using the CZ method shown, 10 single crystal silicon are pulled so that the crystal diameter of the straight body portion is 200 mm, and the solidification rate of the crystal at the end of the straight body portion reaches 90%.

[0092] The carbon concentration used in raw materials is about 5.0×10 14 atoms / cm 3 Of polysilicon.

[0093] As the pulling conditions, a transverse magnetic field is applied to the raw material melt during crystal pulling, the rotation speed of the quartz crucible filled with the raw material melt is 0.1 to 1.0 rpm, and the crystal rotation speed is controlled in the range of 15 to 25 rpm, so that The pulling speed of the crystal straight body part is 1.0-1.3mm / min. It should be noted that the effective segregation coefficient calculated by considering these working conditions is 0.082.

[0094] In addition, the flow rate Q of argon gas is 150 L / min, the pressure P in the furnace is 30 Torr, the open...

Embodiment 2

[0101] The distance Y from the surface of the raw material melt to the lower end of the radiation shield is 40mm, the flow rate Q of argon is 80L / min, the pressure P in the furnace is 50 Torr, and the opening diameter X of the radiation shield is 250mm. At a position 8-20 mm above the surface of the raw material melt, at least the flow rate A of argon gas from the beginning of the melting of the raw material until the solidification rate of the pulled crystal reaches 30% is 0.2-25 m / sec. In addition, The reduction rate of the total power of the side heater and the bottom heater from when the seed crystal comes into contact with the aforementioned raw material melt until the solidification rate of the pulled crystal reaches 30%, the side heater Except for the reduction rate of power of 13%, 10 pieces of single crystal silicon were pulled in the same manner as in Example 1, and the carbon concentration was measured. The graph of the relationship between the carbon concentration a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com