A kind of zero-creep low-temperature rubber rubber and its preparation method

A zero-creep, elastic technology, applied in adhesive types, mineral oil hydrocarbon copolymer adhesives, rosin adhesives, etc., can solve the problem of holes in the bottom film, easily scalded bottom film, affecting product appearance, etc. problem, to achieve excellent coating performance, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Naphthenic oil 20KG; SBC (thermoplastic styrene-butadiene rubber) 25KG; hydrogenated rosin resin 35KG; hydrogenated petroleum resin 15KG; pure C9 hydrogenated petroleum resin 5KG; antioxidant 1010 0.6KG / 100KG.

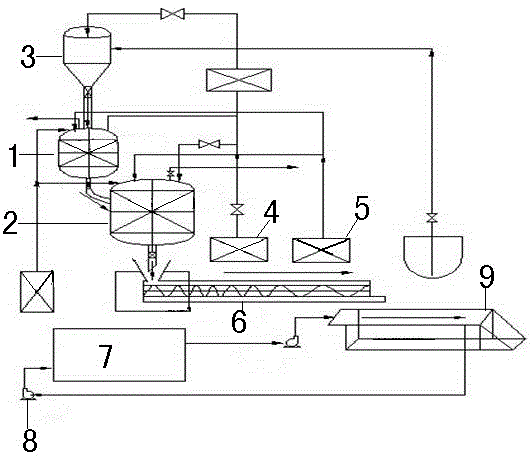

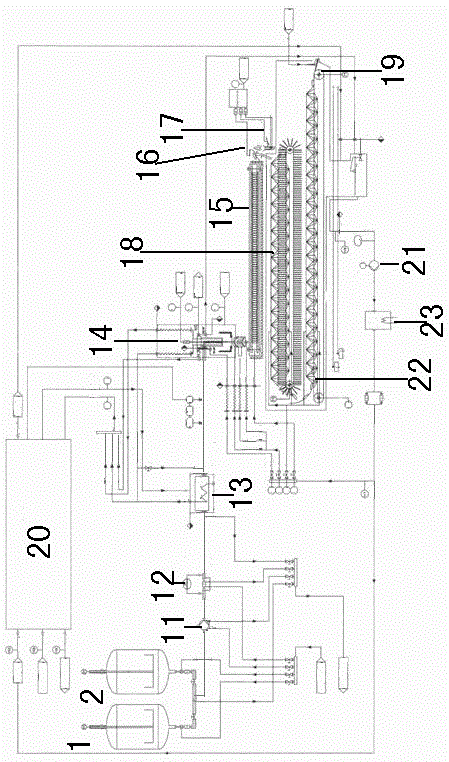

[0024] Process flow:

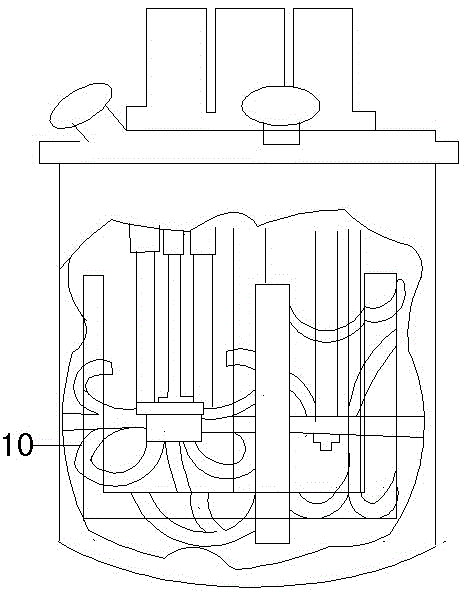

[0025] First put naphthenic oil and antioxidant 1010 into the 300L reaction kettle A1 filled with nitrogen through the gear pump (the air compressor 5 pressurizes the nitrogen in the nitrogen bottle to the reaction kettle A1) to heat, turn on the stirring motor, and gradually adjust the speed to 15~25r / min, after the temperature rises to 70~80°C, suck half of the SBC through the vacuum feeding device 3, turn on the stirring motor at a low level during the feeding process, and stir the materials evenly. Then gradually adjust the motor speed to 120r / min. After the temperature of the material rises to 100~120°C, gradually add the remaining SBC. The feeding method is the same as above, and set the heating nest temperature of the reactor A1 at...

Embodiment 2

[0030] Naphthenic oil 10KG; paraffin-based white oil 5KG; SIS 25KG; hydrogenated rosin resin 15KG; hydrogenated petroleum resin 30KG; pure C9 hydrogenated petroleum resin 15KG; antioxidant 1010 0.8KG / 100KG.

[0031]First put naphthenic oil, paraffin-based white oil and antioxidant 1010 into the 300L reaction kettle A1 filled with nitrogen through the gear pump (the air compressor 5 pressurizes the nitrogen in the nitrogen bottle to the reaction kettle A1) to heat, and start stirring The rotation speed of the motor is gradually adjusted to 15~25r / min. After the temperature rises to 70~80°C, half of the SIS is sucked through the vacuum feeding device 3. During the feeding process, the stirring motor is turned on at a low level, and the material is stirred evenly. Then gradually adjust the motor speed to 120r / min. After the temperature of the material rises to 100~120°C, gradually add the remaining SIS. The feeding method is the same as above, and set the heating nest temperature...

Embodiment 3

[0036] Naphthenic oil 15KG; SIS 25KG; hydrogenated rosin resin 25KG; hydrogenated petroleum resin 25KG; pure C9 hydrogenated petroleum resin 10KG; antioxidant 1010 0.8KG / 100KG.

[0037] First put naphthenic oil and antioxidant 1010 into the 300L reaction kettle A1 filled with nitrogen through the gear pump (the air compressor 5 pressurizes the nitrogen in the nitrogen bottle to the reaction kettle A1) to heat, turn on the stirring motor, and gradually adjust the speed After the temperature reaches 15~25r / min, when the temperature rises to 70~80°C, half of the SIS is sucked through the vacuum feeding device 3, and the stirring motor is turned on at a low level during the feeding process, and the material is stirred evenly. Then gradually adjust the motor speed to 120r / min. After the temperature of the material rises to 100~120°C, gradually add the remaining SIS. The feeding method is the same as above, and set the heating nest temperature of the reactor A1 at 160~180°C; after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com