A graphene-based water-based ink and its inkjet printing transparent patterned conductive electrode application

A kind of alkenyl water-based and graphene technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, application, printing, etc., can solve the problems of inkjet pattern conductivity to be improved, and achieve excellent conductivity and transparency, Effect of low post-treatment temperature and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

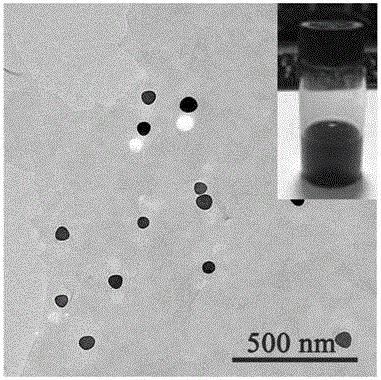

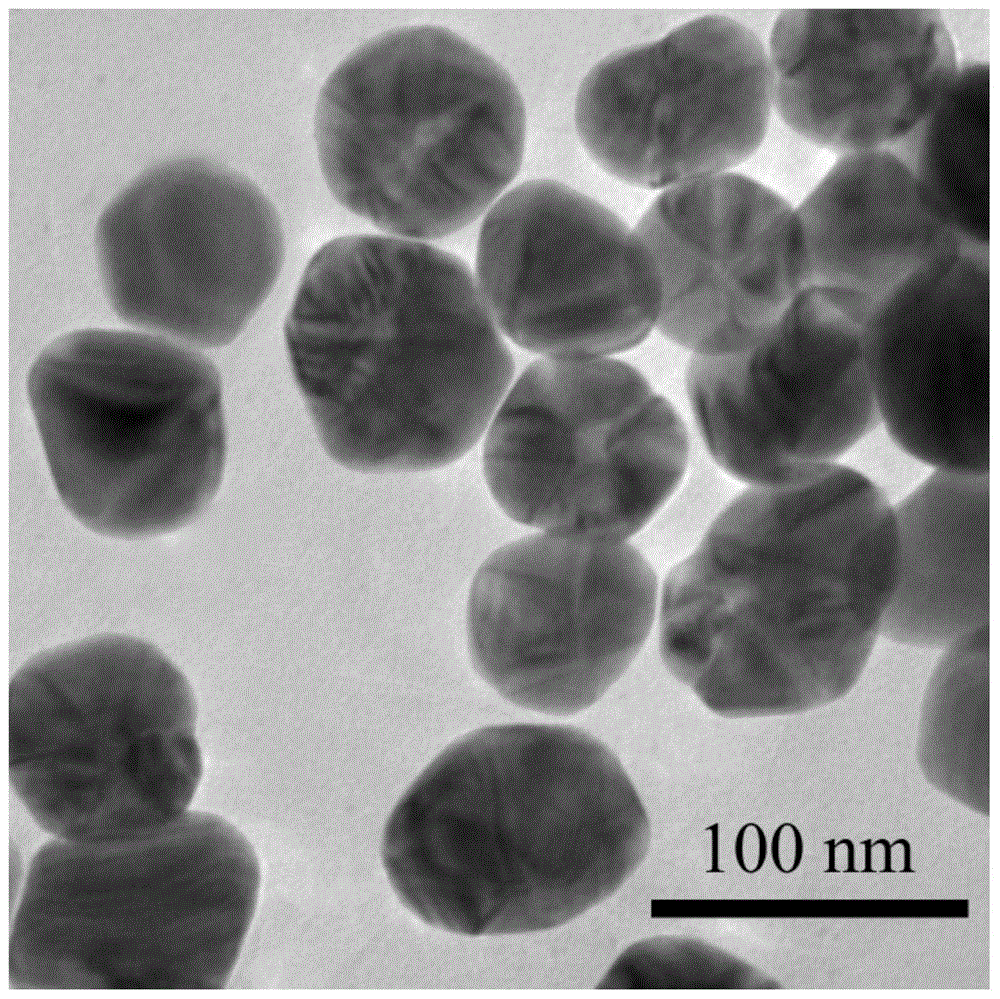

[0029] The graphene-based water-based ink is composed of a composite of graphene oxide and silver nanoparticles and water, the mass fraction of the composite of graphene oxide and silver nanoparticles is 2.4%, and the mass ratio of graphene oxide to silver nanoparticles is 0.5; The diameter of graphene is less than 2 μm; the particle diameter of silver nanoparticles is less than 100 nm.

[0030] Synthesis of graphene oxide: the graphene oxide prepared by the improved Hummer method is a golden yellow product; the product is treated with an ultrasonic crusher 200W for 2 hours, and then passed through a 1 μM filter membrane to remove large-scale graphene oxide; the obtained solid is in Vacuum-dried overnight at room temperature to obtain the obtained product.

[0031] Synthesis of silver nanoparticles: 100 μL of 10 wt% sodium citrate solution and 50 μL of 10 wt% silver nitrate solution were added to 1 mL of water, and stirred at room temperature until the color changed from white...

Embodiment 2

[0036] The graphene-based water-based ink is composed of a composite of graphene oxide and silver nanoparticles and an acetone solution with a volume fraction of 20%, the mass fraction of the composite of graphene oxide and silver nanoparticles is 4.5%, and the composite of graphene oxide and silver nanoparticles is The mass ratio of the particles is 0.2; the diameter of the graphene oxide is less than 2 μm; the particle diameter of the silver nanoparticles is less than 100 nm.

[0037] Synthesis of graphene oxide: the graphene oxide prepared by the improved Hummer method is a golden yellow product; the product is treated with an ultrasonic crusher at 200W for 2 hours, and then passed through a 1 μM filter membrane to remove large-sized graphene oxide; the obtained solid Vacuum-dried overnight at room temperature to obtain the obtained product.

[0038] Synthesis of silver nanoparticles: 100 μL of 0.1mol / L sodium citrate solution and 45 μL of 0.1mol / L silver nitrate solution w...

Embodiment 3

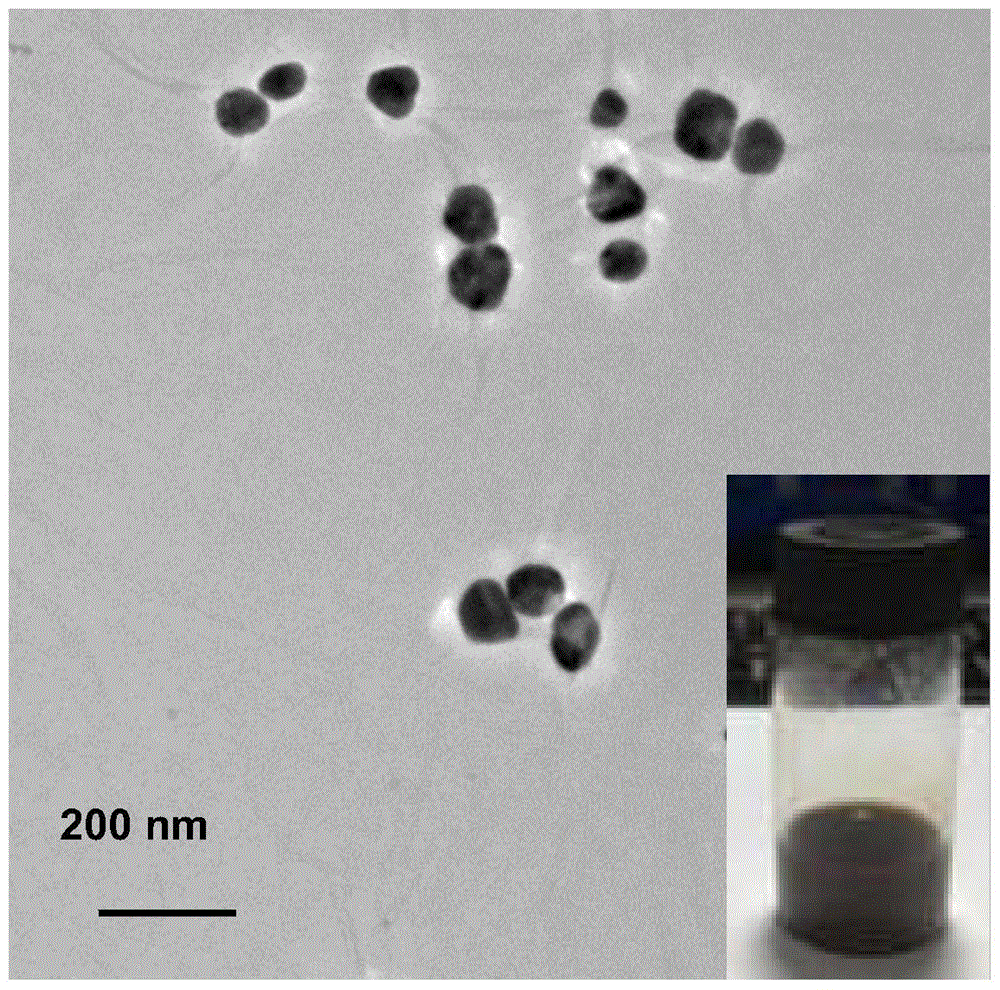

[0043] Graphene-based water-based ink consists of a composite of graphene and silver nanoparticles and a saturated aqueous solution of ethyl acetate at 30°C. The mass fraction of the composite of graphene and silver nanoparticles is 3.1%. Graphene is obtained by liquid phase exfoliation , the mass ratio of graphene to silver nanoparticles is 0.15; the diameter of graphene is less than 2 μm; the particle diameter of silver nanoparticles is less than 100 nm.

[0044] Synthesis of silver nanoparticles: 100 μL of 10wt% tartaric acid solution and 50 μL of 10wt% silver nitrate solution were added to 1 mL of water, stirred at room temperature until the color changed from white to colorless to obtain mixed solution A; 49 μL of 0.1mol / Mix L of ascorbic acid and 49 μL of 5mmol / L potassium iodide, add it to water at 80°C whose volume is 1000 times that of the ascorbic acid solution, and stir evenly to obtain a mixed solution B; after heating the mixed solution B to boil, inject the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com