Method for separating byproducts C9-C10 fractions in ethylene preparation through petroleum cracking and increasing yield

A technology for petroleum cracking and by-products, applied in distillation purification/separation, depolymerization hydrocarbon production, organic chemistry, etc., can solve the problems of polymethylstyrene, large reflux ratio, loss, etc., to simplify the separation steps and reduce the separation Energy consumption, the effect of avoiding mutual aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

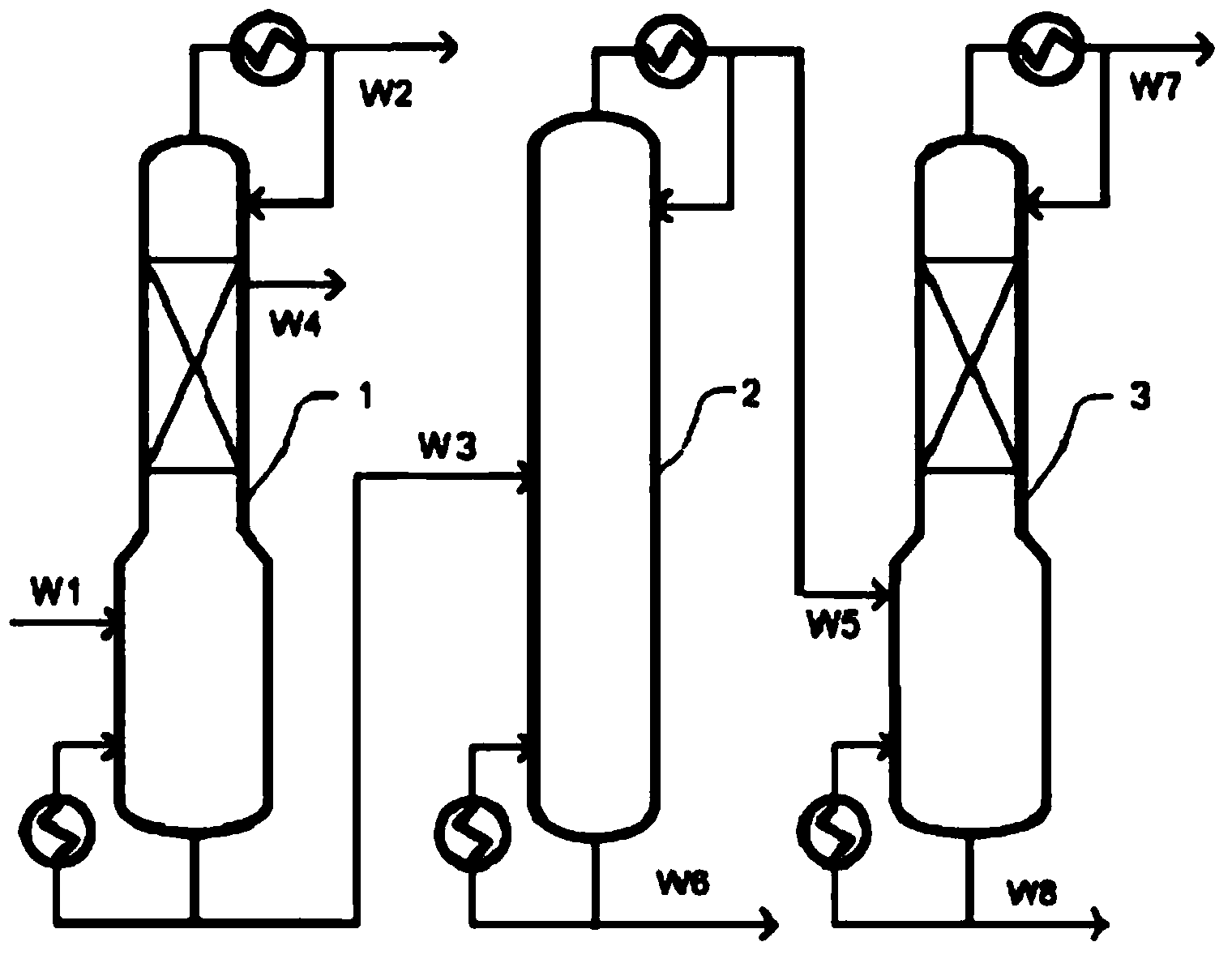

[0032] A method for separating C9-C10 fractions of ethylene by-products from petroleum cracking and improving the yield, comprising the following steps:

[0033] (1) Depolymerize and rectify the C9-C10 fraction through the first depolymerization and rectification tower 1, obtain the cyclopentadiene fraction at the top of the tower, obtain methylcyclopentadiene from the side line, and obtain the remaining fraction at the bottom of the tower; among them, the depolymerization The reaction temperature is 160-220°C, the tower top temperature is 36-50°C, the tower top pressure is 1-10KPaG, the side line temperature is 65-80°C, and the reflux ratio is 1-5;

[0034] (2) Enter the first vacuum rectification tower 2 with the tower still cut of step (1) gained and carry out vacuum distillation, and tower top obtains styrene, methylstyrene cut, and tower still cut; Wherein, tower still temperature is 115~125℃, the temperature at the top of the tower is 80~90℃, the pressure at the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com