Aluminum oxide storage bin

An alumina and silo technology, applied in the field of silo, can solve the problems of high civil construction cost and high foundation, and achieve the effects of reducing civil construction cost, high utilization rate of warehouse capacity and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

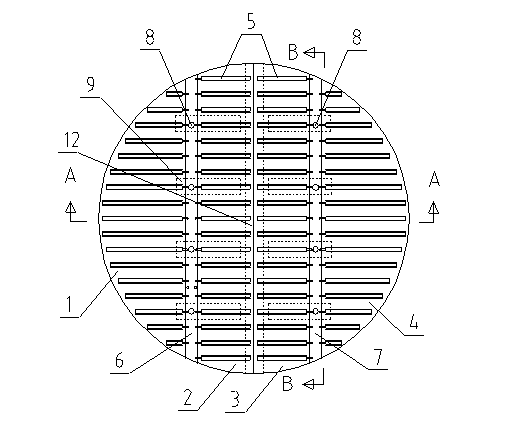

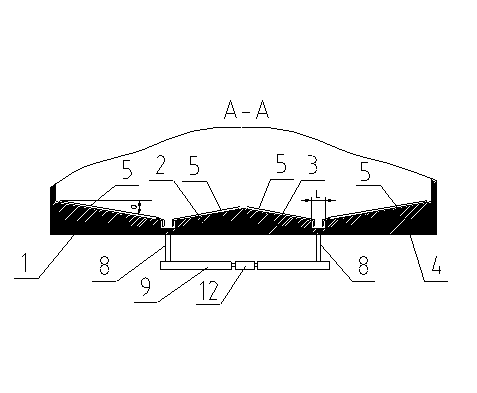

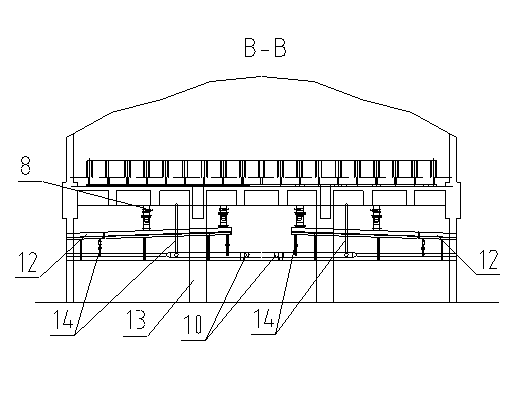

[0017] to combine figure 1 , figure 2 and image 3 , an alumina silo, the diameter of the alumina silo is greater than 18m, and the bottom of the silo is composed of a first bottom plate 1, a second bottom plate 2, a third bottom plate 3 and a fourth bottom plate 4 which are sequentially sealed and connected, along the In the direction from the first bottom plate 1 to the fourth bottom plate 4, the upper surfaces of the first bottom plate 1 and the third bottom plate 3 are inclined downward, and the upper surfaces of the second bottom plate 2 and the fourth bottom plate 4 are inclined upward, and the first bottom plate 1. The inclinations of the second bottom plate 2, the third bottom plate 3 and the fourth bottom plate 4 are all α, and α=10°, the material flows out of the warehouse by itself, without auxiliary clearing equipment, along the first bottom plate 1 and the second bottom plate 2 is provided with a first feeding ditch 6, along the junction of the third base plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com