Intelligent ground centralized flexible conveying system

A conveying system, centralized and released technology, applied in the field of intelligent ground centralized and released flexible conveying system, can solve problems such as complex foundation, complex chain structure, and difficult control of fault points, and achieve small cross-section and foundation, simple and reliable structure, and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

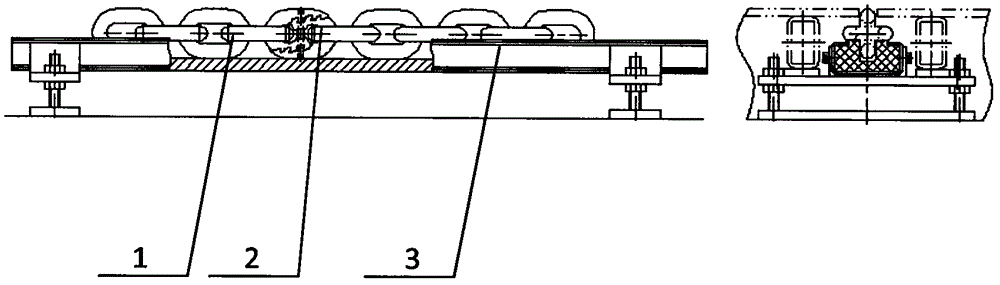

[0027] As one of the best embodiments of the intelligent ground level flexible conveying system of the present invention, see the attached Figure 1~5 , which includes a chain 1, a connecting link 2, a track 3, a collecting trolley, a driving device, a stopper and a switch actuator.

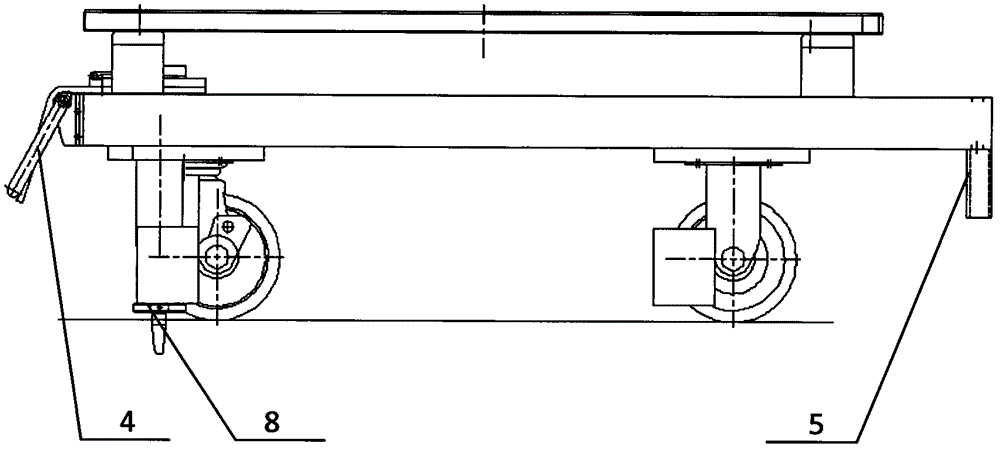

[0028] The collection and release trolley is also provided with a collection and release rod 4, and the stop rod 7 of the stopper presses down the collection and release rod of the assembly trolley so that the traction pin of the assembly trolley is pulled out from the traction chain.

[0029] The tail end of the collection and release trolley is also provided with a blocking rod 5 for the collection and release of the trolley.

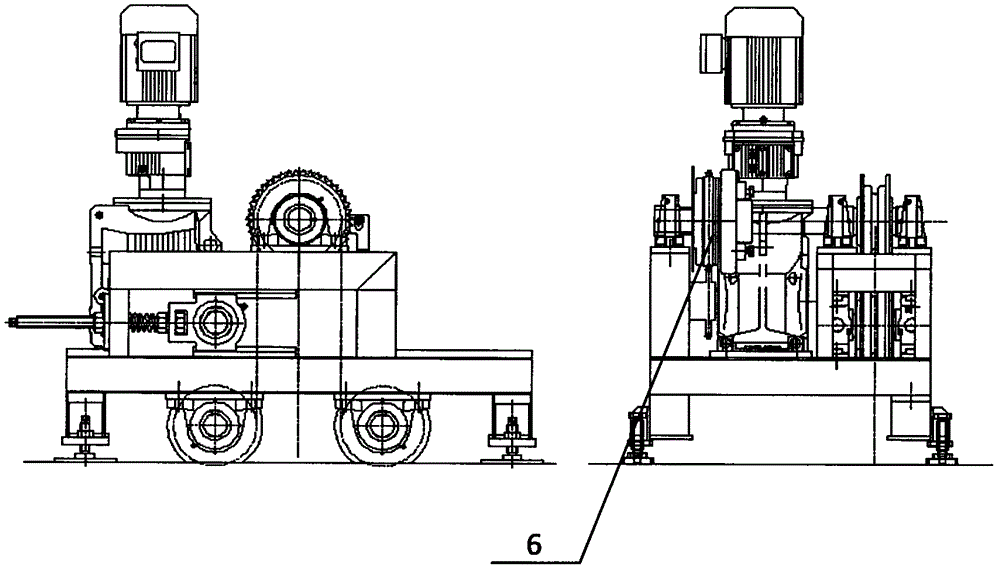

[0030] The driving device is divided into the ground driving device arranged on the ground. The ground driving device is a developed structure with protection, which is very conducive to repair and maintenance, and is equipped with a torque limiter 6, which can effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com