High-temperature-resistant laminate based on steel wire gauze pad damping structure

A technology of steel mesh pad and vibration damping structure, which is applied in the field of aerospace, can solve the problems of inconvenient maintenance, inspection and replacement, the inability to reduce the vibration level, and the inability to disassemble separately, and achieve the effect of simple structure, low cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

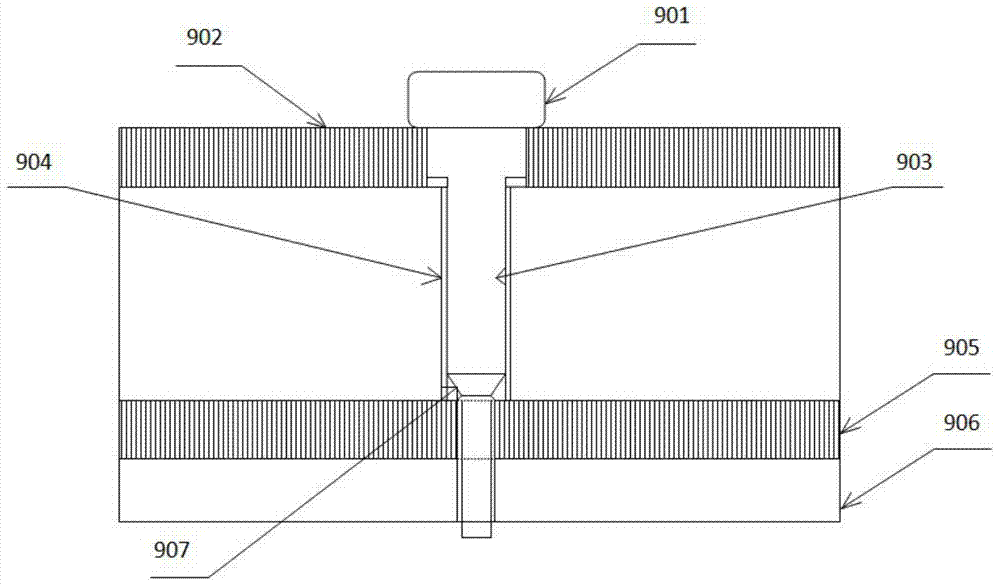

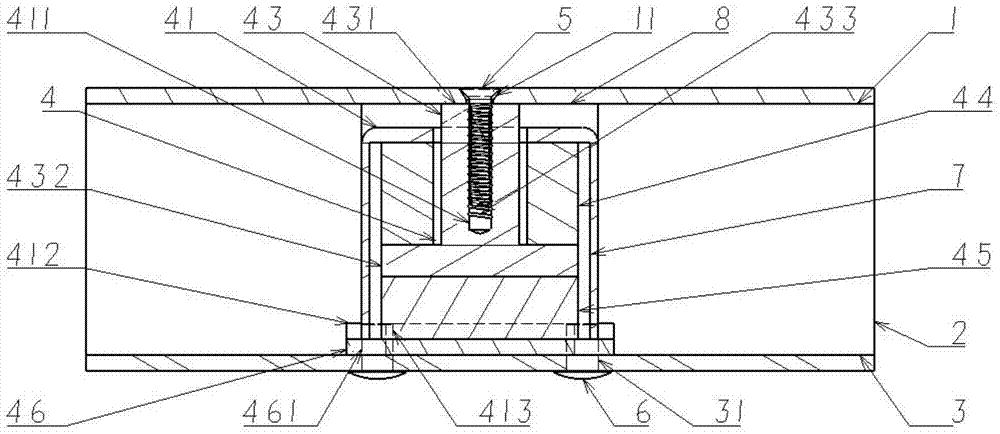

[0026] A high-temperature-resistant laminated board based on a steel wire mesh cushion damping structure according to the present invention includes an outer protective layer (1), a middle heat insulation layer (2), and an inner structural layer (3). In that: it also includes a steel wire mesh cushion damping structure (4); the steel mesh cushion damping structure (4) is arranged between the protective layer (1) and the structural layer (3) and is nested In the middle of the heat insulation layer (2); the steel mesh cushion damping structure (4) has an outer cylinder (41) and a first steel mesh horizontally arranged up and down inside the outer cylinder (41) A pad (44) and a second steel mesh pad (45); the second steel mesh pad (45) is placed on a bottom plate (46) whose lower surface is in contact with the upper surface of the structural layer (3). Among them, the material of the protective layer (1) is a high temperature resistant alloy, the material of the middle heat insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com