Precast concrete members connected by locking and anchoring pier heads and grouting variable diameter sleeve, prefabricated concrete member and manufacturing method of prefabricated concrete member

A technology of prefabricated concrete and prefabricated components, applied to building components, structural elements, building reinforcements, etc., can solve the problems of continuous collapse of buildings, low reliability, and insufficient durability verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

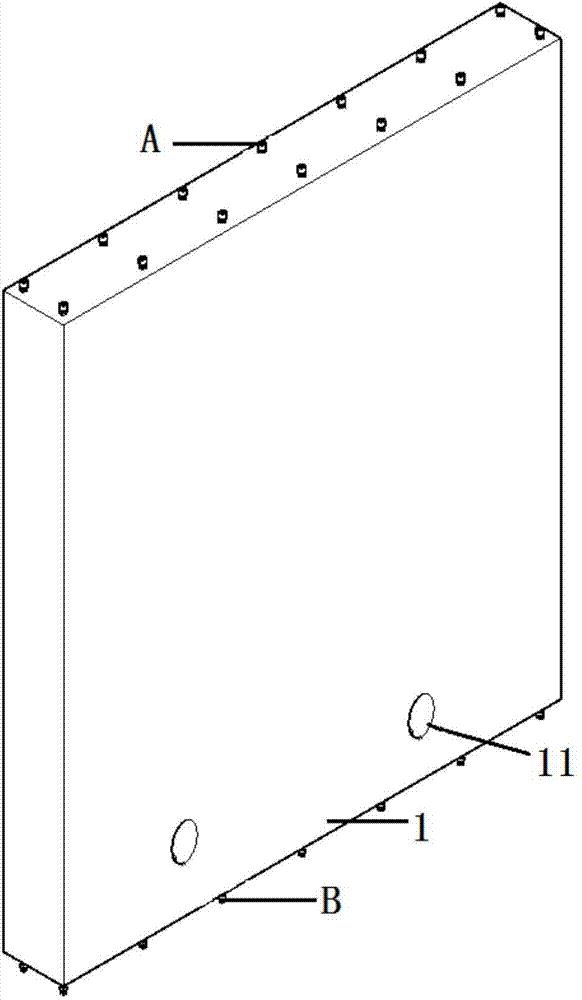

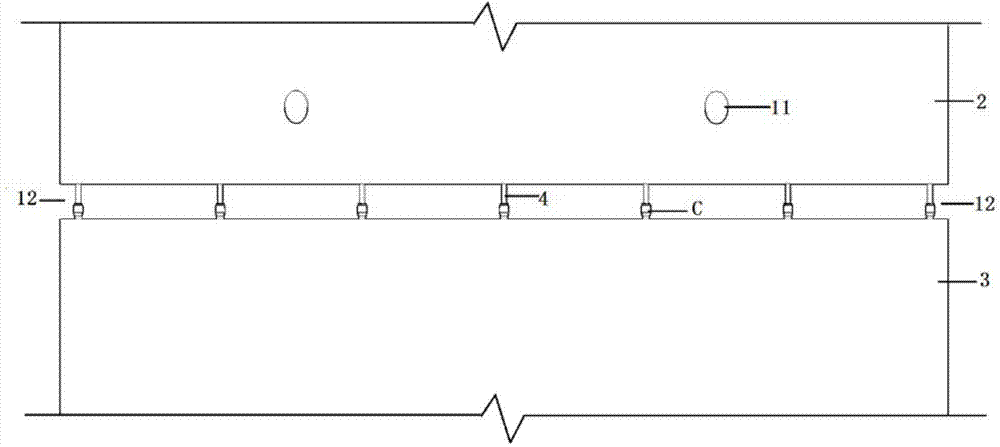

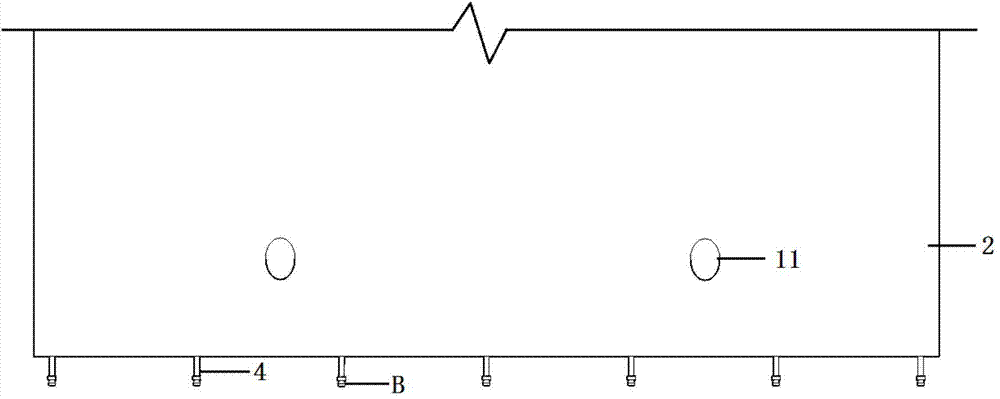

[0037] This embodiment takes the prefabricated concrete components used for vertical connection to form an assembled prefabricated shear wall as an example to describe in detail.

[0038] Such as Figure 1 to Figure 13 As shown, the assembled concrete shear wall connected by the pier head lock anchor grouting variable diameter sleeve is composed of prefabricated concrete shear wall connected by the pier head lock anchor grouting variable diameter sleeve in the cast-in-place zone; The prefabricated components are the upper wall and the lower wall.

[0039]The assembled concrete member connected by the locking anchor grouting variable diameter sleeve of the pier head includes the vertical reinforcement 4 of the upper wall, the vertical reinforcement 13 of the lower wall, the vertical reinforcement 4 of the upper wall and the vertical reinforcement 13 of the lower wall pass through The sleeves 7 are connected to each other; the upper end of the sleeve 7 is provided with an inter...

Embodiment 2

[0052] Such as Figure 14-15 As shown, in this embodiment, the prefabricated concrete beams and assembled concrete beams connected by the pier head lock and anchor grouting reducing sleeve are similar to those in Embodiment 1, and can be referred to Figure 1-9 . The prefabricated component is a prefabricated concrete beam: one side prefabricated beam 18 and the other side prefabricated beam 19, and the one side prefabricated beam 18 and the other side prefabricated beam 19 are connected by a sleeve. The difference is that there is no need to set construction holes in the prefabricated beam 18 on one side and the prefabricated beam 19 on the other side, and the concrete is poured directly between the prefabricated beam 18 on one side and the prefabricated beam 19 on the other side to form a cast-in-place belt; One side also has a plugging pad; a grouting hole and a grouting hole will be set on the sleeve 7 tops placed horizontally, and grouting begins from the grouting hole u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com