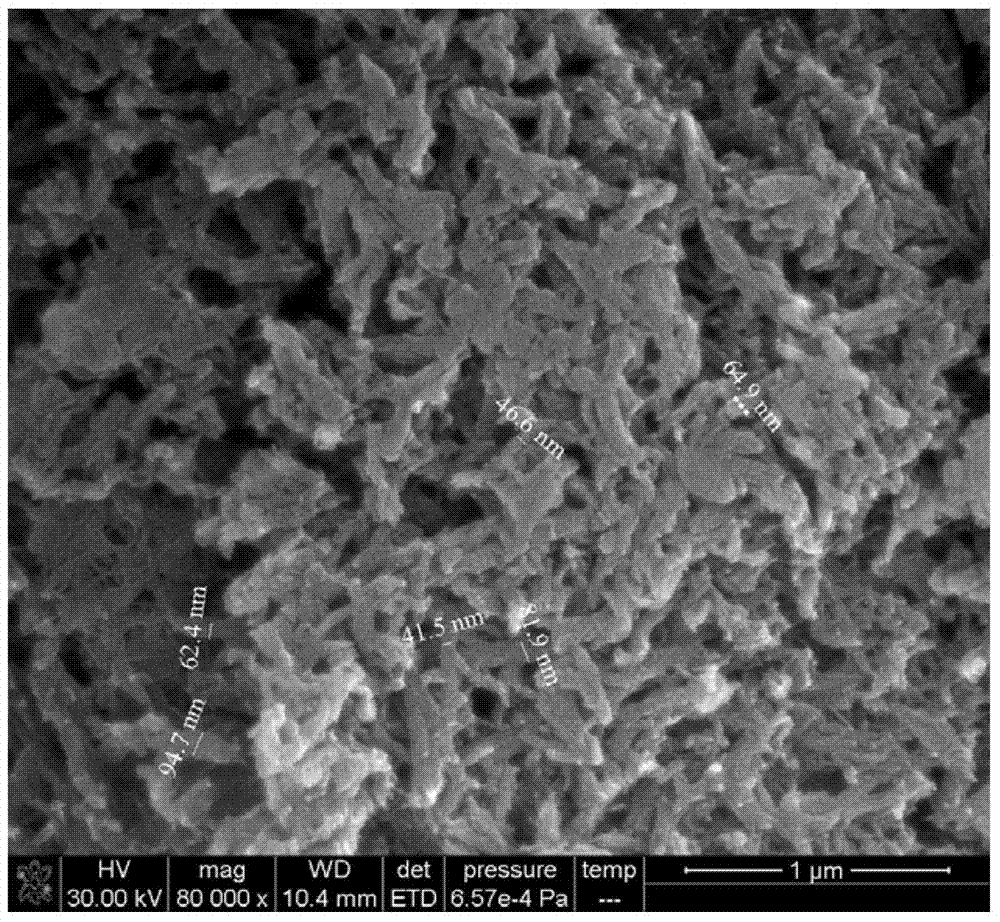

Porous polyaniline-doped nano fiber material with three-dimensional structure as well as preparation method and application of porous polyaniline-doped nano fiber material

A three-dimensional structure, nanofiber technology, used in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., to achieve good cycle life, mild reaction conditions, and high specific capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Dissolve 4.0 mL of aniline in 100 mL of 1.0 mol / L hydrochloric acid solution, and magnetically stir for 30 min at a speed of 60 r / min to obtain solution A;

[0037] 2) Under the stirring speed of 60r / min, slowly add 4.0mL of 0.05wt% Nafion ethanol solution (V AN :V Nafion =100:1), the dropping rate is 2.0mL / min, and the magnetic stirring is 20min to obtain solution B;

[0038] 3) Under the stirring speed of 60r / min, add MnO to the solution B obtained in step 2) 2 (n AN :n MnO2 =1:1), at room temperature, magnetic stirring for 12h to obtain latex liquid C;

[0039] 4) Suction and filter the latex liquid C, collect the product (ie filter cake), and wash the product with ethanol, acetone and double distilled water in sequence until the filtrate is colorless and NaOH does not detect Mn 2+ ion;

[0040] 5) Dry the washed product in vacuum at 60° C. for 24 hours to obtain dark green powder, namely Nafion-doped polyaniline nanofiber material (hereinafter referred to as PANI-Nafi...

Embodiment 2

[0061] 1) Dissolve 4.0 mL of aniline in 100 mL of 1.0 mol / L hydrochloric acid solution, and magnetically stir for 30 min at a speed of 60 r / min to obtain solution A;

[0062] 2) Under the stirring speed of 60r / min, add 4.0 mL of the ethanol solution of sodium lauryl sulfate (V) to the solution A obtained in step 1). AN :V surf =1:1), the dropping rate is 0.25~2.5mL / min, and the magnetic stirring is 30min to obtain solution B;

[0063] 3) Under a stirring speed of 100r / min, slowly add MnO to the solution B obtained in step 2) 2 (n AN :n MnO2 =1:2), magnetically stirred at 15°C for 8 hours to obtain latex liquid C;

[0064] 4) Suction the latex liquid C, collect the product (ie filter cake), and wash the product with ethanol, acetone and double distilled water in sequence until the filtrate is colorless, and NaOH does not detect Mn 2+ ion;

[0065] 5) Vacuum drying the washed product at 50° C. for 24 hours to obtain dark green powder, which is the porous three-dimensional structure d...

Embodiment 3

[0068] 1) Dissolve 4.0 mL of freshly distilled aniline (ie, aniline collected by distillation under reduced pressure) in 100 mL of 1.5 mol / L hydrochloric acid solution, and magnetically stir at a speed of 50 r / min for 25 min to obtain solution A;

[0069] 2) Under the stirring speed of 80r / min, add 4.0 mL of ethanol solution of sodium lauryl sulfate (V) to the solution A obtained in step 1). AN :V surf =1:1), the dropping rate is 0.25~2.5mL / min, and the magnetic stirring is 30min to obtain solution B;

[0070] 3) Under the stirring speed of 100r / min, slowly add ammonium persulfate (n AN :n Ammonium persulfate =1:0.5), magnetically stirred at 30°C for 24h to obtain latex liquid C;

[0071] 4) Suction the latex liquid C, collect the product (ie filter cake), and wash the product with ethanol, acetone and double distilled water in sequence until the filtrate is colorless and N a OH cannot detect Mn 2+ ion;

[0072] 5) Vacuum drying the washed product at 60° C. for 20 hours to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com