Treatment method of waste water from firecracker paper making

A technology for papermaking wastewater and treatment methods, which is applied in the direction of processing wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of high concentration of organic pollutants in the effluent, paralysis, and unstable biochemical systems, etc., to achieve The effects of sufficient CODcr removal, strong adaptability to temperature changes, and enhanced anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

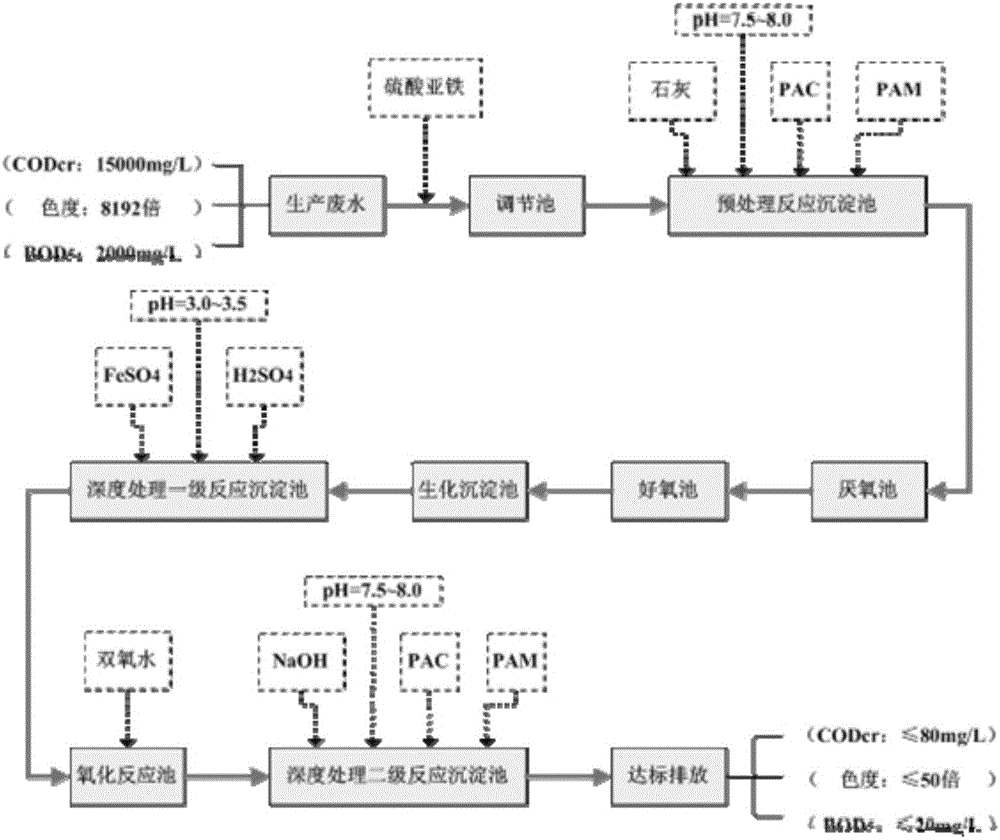

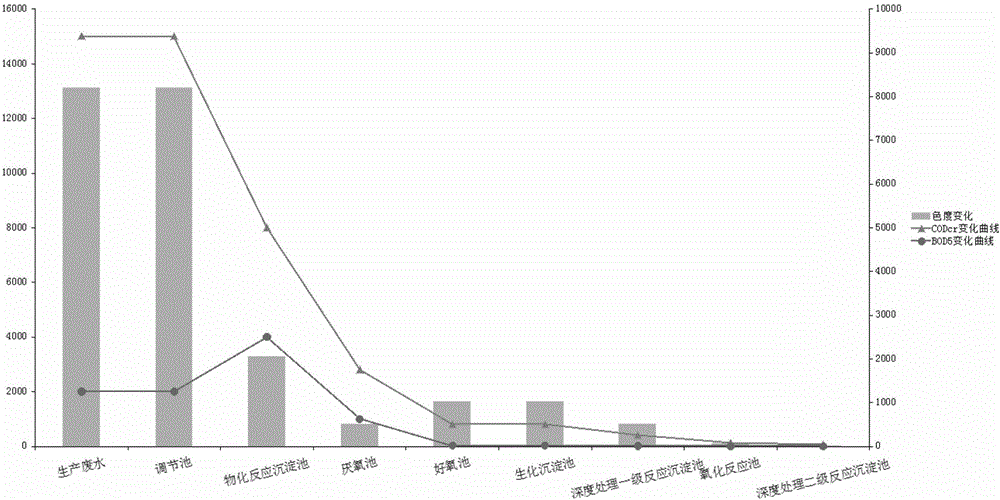

[0041] This embodiment is a treatment method for firecracker paper papermaking wastewater, and its process flow chart can be found in figure 1 , including the following steps:

[0042] (1) The waste water from the firecracker paper making is input into the adjustment tank and the pretreatment reaction sedimentation tank in sequence;

[0043] Add ferrous sulfate at the water inlet end of regulating tank, the dosage of described ferrous sulfate is 1.5kg / t, and it effectively prolongs the contact time of ferrous ion and organic dye molecule (as: rhodamine), makes The full reaction means that the complexation is sufficient; at the same time, the hydraulic retention time HRT in the adjustment pool is controlled to be 12h.

[0044] The pretreatment reaction sedimentation tank is divided into a reaction zone and a precipitation zone, and lime, PAC and PAM are added in the reaction zone, and the pH is adjusted to be 7.5-8.0; the dosage of the lime, PAC and PAM is respectively 0.5kg / ...

Embodiment 2

[0072] 1. Purpose of the experiment

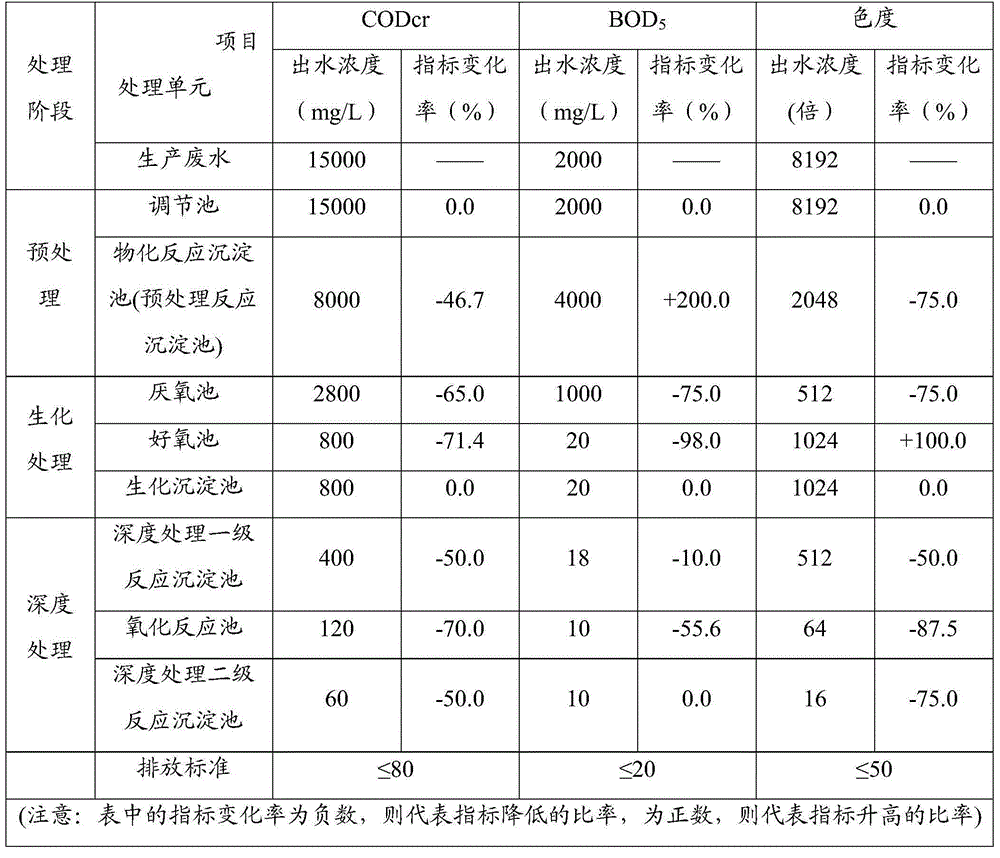

[0073] The treatment effect of the wastewater treatment method described in Example 1 was evaluated by comparative analysis.

[0074] 2. Experimental method

[0075] This experiment is divided into control group and experimental group, wherein, the processing technology of control group and experimental group is as table 2: comparative example 1 and embodiment This comparative example is to adopt conventional process, pretreatment+biochemical treatment+conventional advanced treatment, and it and The process comparison and treatment effect comparison table of the treatment method described in embodiment 1 are as table 2:

[0076] Table 2 The treatment process comparison table of the control group and the experimental group

[0077]

[0078]

[0079] 3. Experimental results

[0080] As can be seen from Table 2: compared with comparative example 1, embodiment 1 can effectively prolong the contact time of dyestuffs such as ferrous iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com